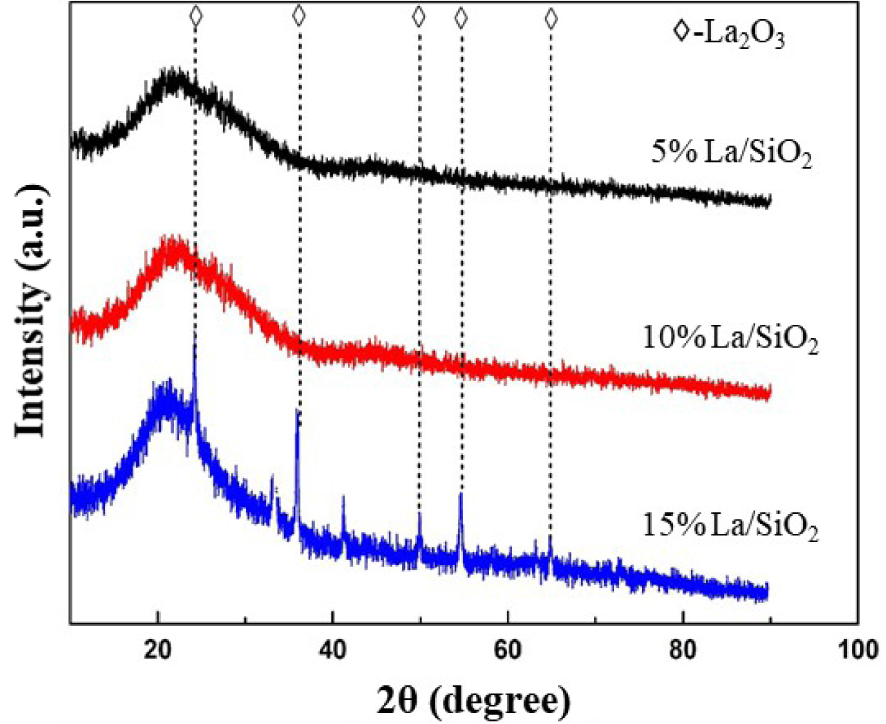

As the result of new, independent investigations, Figure 12 and the corresponding discussion have to be retracted:

“In Figure 12, when the loadings of La are 5% and 10%, the diffraction peak of lanthanum oxide crystal does not appear, indicating lanthanum oxides are highly dispersed on the surface of SiO2 at the current loading. When the loading of La is increased to 15%, a weak diffraction peak appears, it is shown that the lanthanum oxides are excessive and cannot be uniformly dispersed on the surface of the carrier. The peak positions are about 25°, 37°, 50°, 55°, and 63°. It is indicated that lanthanum oxide crystals begin to appear on the catalyst surface. Combined with the conclusion: 15% La∕SiO2 > 10% La∕SiO2 > 5% La∕SiO2, it is indicated the best loading of La∕SiO2 is between 10% and 15%.”

XRD images of La∕SiO2 with different loadings (Figure 12 in original paper).

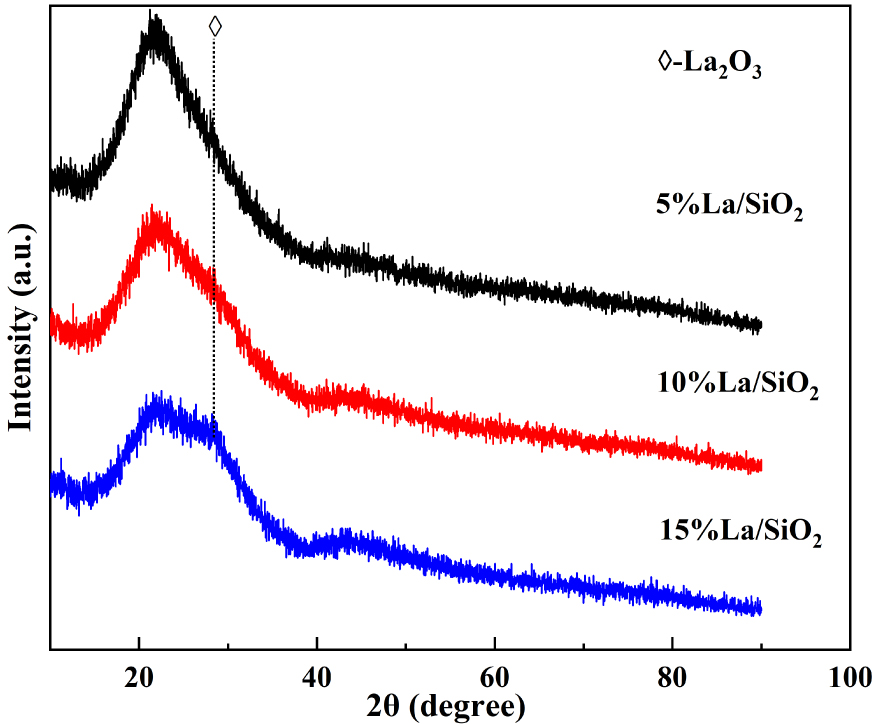

and should be replaced with the new Figure 12 and the corresponding discussion:

“It can be seen from Figure 12 that when the loading of La is 5% and 10%, the diffraction peaks of crystalline lanthanum oxide do not appear, indicating that under these conditions, lanthanum oxide is in a highly dispersed state on the surface of the SiO2. However, when the La loading is increased to 15%, a weak diffraction peak appears at about 28° (Figure 12), but there are still no sharp diffraction peaks, which indicates that lanthanum oxide is not uniformly dispersed on the surface of the carrier and lanthanum oxide crystals begin to appear on the surface of the catalyst. Combining the conclusion that loadings of 15%La∕SiO2 and 10%La∕SiO2 lead to high catalytic activity with the XRD characterization, the optimal loading of La∕SiO2 catalyst is between 10%–15%.”

XRD images of La∕SiO2 catalysts with different catalyst loading (obtained after control experiments).

The authors deeply apologize for the inconvenience caused.

CC-BY 4.0

CC-BY 4.0