Version française abrégée

1 Introduction

Le stockage souterrain de dioxyde de carbone rencontre en Pologne un d'intérêt toujours croissant [9,10]. Le but de cet article est de montrer les secteurs industriels émetteurs de grandes quantités de CO2 et qui, dans un proche avenir, peuvent faire l'objet d'une séquestration souterraine en Pologne. Les émissions de CO2 des catégories « énergie » et « procédés industriels », les concentrations dans le flux des gaz de combustion ainsi que la localisation des importantes sources ponctuelles d'émission de CO2 ont été analysées.

2 Origine des données

Les données sur les émissions de CO2 proviennent des études statistiques officielles, des collectivités locales, du secteur industriel et de la documentation. Dans ce domaine, le rapport du Centre de l'inventaire des émissions présente un intérêt fondamental [4].

3 Catégories d'émission de CO2

Les plus grandes sources d'émission de dioxyde de carbone en Pologne sont les secteurs industriels appartenant aux catégories (d'après la méthodologie IPCC) « énergie » et « procédés industriels ». La part d'émission des autres catégories est insignifiante (Tableau 1). La catégorie « énergie » est responsable d'environ 96 % des émissions totales ; les 4 % restant reviennent à la catégorie « procédés industriels ».

Inventory of CO2 emissions from individual categories of industry in Poland in the year 2000 (data after [1])

Inventaire des émissions de CO2 en 2000 des différentes catégories d'industries en Pologne (données provenant de [1])

| GHG emission categories | CO2 emission [Mt] |

| Energy | 302.46 |

| Fuel combustion | 302.28 |

| Fugitive emissions from fuels | 0.184 |

| Industrial processes | 12.35 |

| Solvent and other product use | 0 |

| Agriculture | 0 |

| Land-use change and forestry | 0 |

| Waste | 0 |

| Other | 0 |

| Total | 314.81 |

3.1 Catégorie « énergie »

Dans la catégorie « énergie », les secteurs industriels appartenant à la sous-catégorie « combustion des carburants » sont les sources dominantes d'émission de CO2 (Tableau 2) ; la plus grande partie de ces émissions provient du secteur énergétique (production d'énergie électrique et thermique). La combustion du charbon est responsable de 45 % des émissions totales de CO2, dont 56 % revient à la houille et 44 % à la lignite [9].

Emission of CO2 from plants of the ‘energy’ category in Poland in the year 2000 (data after [4])

Emission de CO2 de la catégorie « énergie » en 2000 en Pologne (données d'après [4])

| Category – Energy | CO2 emission [Mt] | Share in category |

| Fuel combustion activities | 302.29 | |

| 1. Energy industries | 176.32 | 58.29 |

| 2. Manufacturing industries and construction | 52.07 | 17.21 |

| 3. Transport | 28.21 | 9.33 |

| 4. Other sectors | 45.40 | 15.01 |

| 5. Other | 0.29 | 0.10 |

| Fugitive emissions from fuels | 0.18 | |

| 1. Solid fuels | 0.00 | 0.00 |

| 2. Oil and natural gas | 0.18 | 0.06 |

| Energy | 302.47 | 100.00 |

3.2 Catégorie « procédés industriels »

En 2000, la part des émissions de CO2 des secteurs industriels appartenant à cette catégorie est de 12,35 Mt. La part des émissions des sous-catégories « produits minéraux » est la plus importante (85,7 %), celles de l'industrie chimique et de la métallurgie représentent respectivement 10,2 et 4,1 % (Tableau 3).

Emission of CO2 from sources of the ‘industrial processes’ category in Poland in the year 2000 (data after [4])

Émission de CO2 de la catégorie « procédés industriels » en 2000 en Pologne (données provenant de [4])

| Category – Industrial processes | CO2 emission (Mt) | Share in category |

| Mineral products | 10.58 | |

| 1. Cement production | 7.52 | 60.93 |

| 2. Lime production | 1.87 | 15.11 |

| 3. Limestone and dolomite use | 0.0 | 0.00 |

| 4. Soda ash production and use | 0.44 | 3.56 |

| 7. Other | 0.75 | 6.04 |

| Chemical industry | 1.26 | |

| 1. Ammonia production | 1.21 | 9.78 |

| 2. Ferroalloys production | 0.0 | 0.00 |

| 4. Carbide production | 0.05 | 0.44 |

| 5. Other | 0.001 | 0.01 |

| Metal production | 0.51 | |

| 1. Iron and steel production | 0.21 | 1.68 |

| 2. Ferroalloys production | 0.22 | 1.77 |

| 3. Aluminium production | 0.08 | 0.68 |

| Industrial processes | 12.35 | 100.00 |

4 Données sur les concentrations de CO2 dans le flux des gaz de combustion/gaz industriels

Les données sur les concentrations de CO2 dans les gaz de combustion/gaz industriels concernent : les centrales à gaz naturel, les centrales à houille et lignite ainsi que les gaz des industries chimiques et des industries métallurgiques [4,6,7]. La concentration de CO2 dans le flux des gaz de combustion des centrales à gaz naturel représente environ 3,3 %, à lignite 8,5 à 13,5 %, à houille 9,5 à 15,2 %. La production de l'ammoniac émet du CO2 pur, celle de la soude 37 %. Certains procédés métallurgiques émettent un flux concentré de dioxyde de carbone.

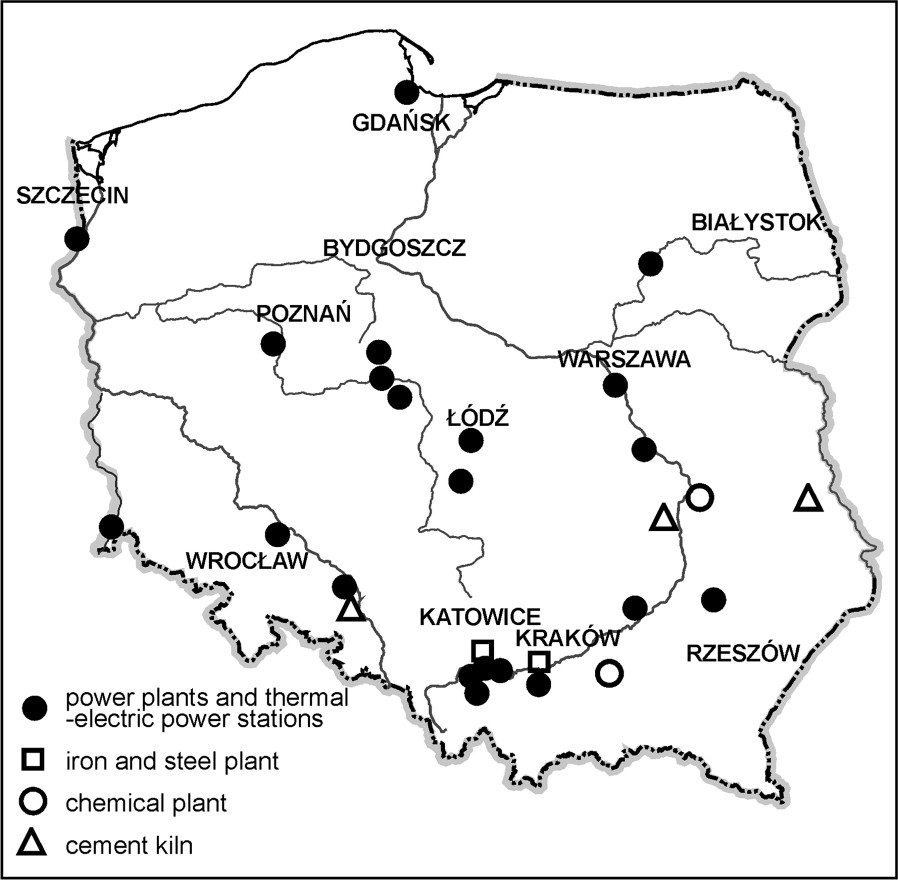

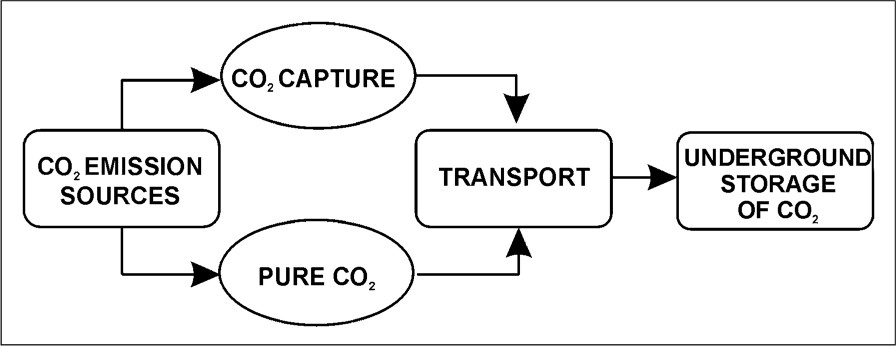

5 Les sources industrielles d'émission de CO2 dans le contexte du stockage souterrain

En Pologne, les émissions annuelles de CO2 des 28 entreprises répertoriées en 2000 dans les secteurs de l'énergie, de l'industrie chimique, de la métallurgie et du ciment dépassent 1 Mt (Fig. 1). Le CO2 émis dans l'atmosphère est un composant des gaz de combustion (teneur jusqu'à quelques dizaines de pourcent) et des gaz industriels (de diverses teneurs au CO2 pur). L'utilisation de ce gaz à des fins de stockage souterrain passe par une séparation (procédés coûteux) des gaz de combustion/industriels [3,5]. Dans le cas d'un flux de CO2 pur, une fois transporté, ce gaz peut être injecté directement sous terre (Fig. 2). Pour des raisons économiques, l'utilisation d'un flux de CO2 pur est plus intéressante, plus particulièrement pour des installations pilotes de stockage souterrain.

Major point sources of emission of CO2 in Poland.

Importantes sources ponctuelles d'émission de CO2 en Pologne.

Gaining CO2 for underground storage from large point sources of emission.

Captage du CO2 des importantes sources ponctuelles d'émission pour son stockage souterrain.

6 Conclusions

L'analyse des données concernant les quantités d'émission de CO2, les informations sur les concentrations de CO2 dans les gaz de combustion et les gaz industriels ainsi que la localisation des grandes sources ponctuelles d'émission peuvent être le point de départ des discussions sur le contrôle souterrain de ce gaz à l'échelle d'un pays donné.

Les secteurs industriels émettant un important flux concentré de CO2 (dans la catégorie « procédés industriels » ; par exemple, la production d'hydrogène, d'ammoniac...) peuvent dans un proche avenir et en priorité être une source de CO2 pour le stockage souterrain.

1 Introduction

The question of sequestration of CO2 by underground storage begins to focus remarkable attention in Poland. This is reflected by ongoing attempts to work out premises for studies on possibilities to store this gas in deep-seated geological oil- and gas-reservoirs and aquifers [9,10]. Moreover, studies aimed at drawing out the basis for building a pilot installation for underground storage of CO2 in an abandoned hydrocarbon deposit are carried out. Poland has experience in underground injection and storage of acid gases and the Central Mining Institute in Katowice participates in the EU RECOPOL Project (5 FP EU), aimed at testing possibilities to inject and store CO2 in deep non-exploitable coal seams.

The aim of this paper is to identify sectors of the Polish industry and single plants that are responsible for emissions of large amounts of CO2 and might be good candidates for a future pilot program of sequestration of this gas by underground storage. The paper also presents estimations of emissions coming from individual categories, sub-categories and sectors of industry, and concentrations of CO2 in combustion gases and those emitted to air by industrial sources, calculated with reference to the methodology of IPCC, and location of the largest point sources of emission of this gas in Poland. Concerning the fact that underground storage of CO2 refers to large point sources, this article does not develop problems of emission from transport (dispersed source of emission), biomass contribution and other greenhouse gases emission, for example methane. The information presented here may be used as a starting point for further studies on possibilities to intercept and sequestrate CO2 emissions by underground storage.

2 Sources of data

The data used in this study include those coming from Polish official statistical analyses of the National Emission Centre affiliated to the Institute of Environmental Protection as well as information provided by agencies of local administration and information provided directly by individual plants of the ‘energy’ and ‘industry’ categories, that are responsible for the major part of the emissions.

A special attention should be paid to a report of the National Emission Centre [4]. The report summarizes emissions of carbon dioxide and other greenhouse gases in Poland. The presented data were processed with reference to structure of emissions and sequestration as given in the methodology recommended by ‘Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories’. Reports of that type, which is based on IPCC methodology, are to be compiled in several countries for the needs of international clearings.

3 Categories of CO2 emissions

In Poland, the bulk of carbon dioxide emissions has its source in industrial sectors assignable in the IPCC approach to the categories ‘energy’ and ‘industrial processes’, whereas the shares of the remaining categories appear negligible (Table 1). The ‘Energy’ category appears to be responsible for about 96% of the national emissions of CO2, estimated at 314.8 Mt for the year 2000 and the ‘industrial processes’ category, comprising CO2 emissions freed in the course of various technological processes not related to production of energy, comprises only about 4% of total emission of this gas.

3.1 Energy category

Sources of CO2 emissions assigned to this category are clearly dominated by those of industrial sectors representing sub-category of fuel combustion activities (Table 2). The bulk (58.3%) of the emissions comes from the energy sector (power and power and heat plants), 17.2% from manufacturing industries and the construction sector, 9.3% from transportation (dispersed sources) and 15.1% from other industrial sectors. CO2 emissions assigned to the sub-category of ‘fugitive emissions from fuels’ represent merely 0.06% of the total CO2 emissions in this category.

In the year 2000, power and power and heat producing plants were responsible for the emission of 164.7 Mt of carbon dioxide, that is 54.5% of emissions in the ‘energy’ category [4]. The share of sectors of petroleum refining and manufacture of solid fuels and other energy industries in emissions of CO2 is small. The share of emissions resulting from combustion of solid fossil fuels is estimated at 98% of this emission, and that of liquid and gaseous fuels at 2%. Polish industry is mainly based on the use of hard coal and lignite, and combustion of these fuels was responsible for 45% of total emissions of CO2, and the share of hard coal is equal to 56%, and that of lignite to 44% [9]. The share of CO2 emissions resulting from combustion of fossil fuels in the sector of manufacturing industries and construction is mainly related to the iron and steel industry (6.6% of total emissions in this category). The shares of chemicals, food processing, pulp paper and print, and non-ferrous metals industries are smaller and that of other industries of this category is equal to 5.6% of the total emissions in this field [4].

3.2 Category of industrial processes

In the year 2000, CO2 emissions from sectors assigned to the category ‘industrial processes’ were estimated at 12.35 Mt (Table 3). The share of the sub-category ‘mineral products’ was equal 85.7% of emissions in this category, that of ‘chemical industry’ 10.2% and that of ‘production of metals’ 4.1%. In the sub-category of mineral products, the share of emissions related to production of cement was the highest (60.9%), markedly higher than those related to production of lime (15.1%) and calcinated soda (3.6%) and all the remaining products (6.0%). In the sub-category ‘chemical industry’, attention should be paid to emissions related to production of ammonia (9.8%) and small share of emissions released in production of carbide and, among emissions classified as related to production of other chemicals, those released in the production of ethylene oxide. The share of the sub-category (production of metals' is generally small (4.1%) and mainly related to the production of iron and steel (especially converter steel, sinters, open-hearth steel and cast iron) and of ferroalloys and aluminium).

4 Data on content of CO2 in streams of combustion and industrial gases

Content of carbon dioxide in gases originating in combustion of fossil fuels depends on the type of fuel and content of elementary carbon, and, in industrial gases, on the processes that generate them. CO2-rich stream is emitted in some technological processes such as those connected with production of ammonia in nitrogen plants, hydrogen, ethylene in petrochemical plants as well as some processes taking place in steelworks [2].

Data on concentration of carbon dioxide in streams of combustion/industrial gases emitted by industry in Poland are given below. The data were obtained directly from plants emitting large quantities of carbon dioxide and were supplemented with those taken from the available literature.

Analysis of composition of combustion gases from two power plants run on natural gas showed that they mainly consist of nitrogen (from 76.3 to 81.7%), oxygen (14 do 15%), water vapour (6.5%), carbon dioxide (3.2 to 3.3%), with small concentrations of other gases. In turn, data from five power plants run on lignite show clearly a higher content of carbon dioxide in combustion gases, ranging from 8.5 to 13.5%. In gases from combustion of hard coal (data from 13 power and power and heat plants), nitrogen clearly predominates (71.6 to 80.8%) over carbon dioxide (9.5 to 15.2%), oxygen (6 to 10%), water vapour (4.8 to 10.1%) and other gases occurring in negligible concentrations (CO, SO2, NOx).

Data from the chemical industry show that air emissions from ammonia plants include: pure carbon dioxide and combustion gases yielding nitrogen, carbon dioxide, oxygen, water vapour and some other gases. In production of urea, installations for methane decomposition, absorption and condensation of NH3 steadily emit gas with the following composition: NH3, 28 kg h−1, CO2, 27 kg h−1, and H2O, 1045 kg h−1 [6]. One of Polish plants that produce calcinated soda is emitting gases with carbon dioxide content equal to 37% of their volume. Strongly concentrated stream of carbon dioxide is also emitted by ethylene-producing petrochemical plants.

In production of iron and steel, concentrations of carbon dioxide in converter gas before CO is burned up over stock hole range from 7 to 14%, and those of CO from 75 to 90%, and O2 from 2.5 to 20% [7]. Concentrations of carbon dioxide in emissions coming from arc (electric) furnaces used for the production of steel is small, ranging from 0.2 do 4.6% of volume of gases, depending on a given phase of this process [8]. In the sintering section of one of Polish iron and steel works, concentration of carbon oxide equals 17% of volume of off-gases (flue-gases), whereas it drops to 1 to 3.5% in such gases from converter processes, that is to similar values as given by Jędrzejowski [7]. Converter gas above metal in converter (before burning it up) yields about 90% of CO and 10% of CO2. Combustion gases from open-hearth furnaces of Polish iron and steel works yield 14–18% of CO2 and 2–5% of O2, whereas contents of CO and SO2 is up to 0.5% and water vapour – up to 25% [8].

5 Industrial sources of CO2 emissions in underground storage context

In year 2000, there were in Poland 28 power and chemical plants and cement kilns, which were responsible for emitting over 1 Mt of CO2 (Fig. 1) [11]. Estimations show that total emission from these plants was equal to 165.6 Mt, which corresponds to 52.6% of the total emission of CO2 in Poland in that year. Energy plants have here the largest share in total emissions of CO2, with the Bełchatów power plant as the largest source of emission on the country scale (over 10% of total emissions). Eight plants are emitting from 5 to 10 Mt of CO2 and 19 from 1 to 5 Mt.

Appropriate geological structures for underground storage of CO2 should be found for these plants. From the three basic elements of underground storage of this gas: capturing, transporting and storing, the first is the one that generates the highest costs. The costs of transport depend on the distance from the source of emission to the storage place. The costs of injection are the lowest and depend on the depth of reservoir and the volume of CO2 injected [3,5].

The high costs of CO2 capture are the main reason why underground storage is not in common use. Industrial examples of underground storage of CO2 (EOR installations, Sleipner installation in the North Sea) show that this operation is technically feasible and can bring economical profit.

CO2 that is emitted to the atmosphere is the component of gases that are produced during fuel combustion (concentration up to tens per cent) and industrial gases (diversified concentration up to pure gas). Using combustion/industrial gases with low concentration CO2 for underground storage purposes needs its separation, which is an expensive process. In case of pure stream of CO2, it is ready for injection underground immediately after transport (Fig. 2). Using pure stream of CO2 is also more interesting, because of economical reasons, especially for pilot installations of underground storage of this gas in order to avoid the emission toward the environment.

6 Conclusions

Analysis of data on the magnitude of CO2 emissions, processed in accordance with the IPCC methodology, provided interesting and comparable results. The results, especially those concerning emissions of the categories ‘energy’ and ‘industrial processes’, along with data on the concentration of CO2 in combustion and industrial gases and location of major point sources of emissions give a good starting point for discussion on the possibilities of sequestration of this gas by underground storage methods on the scale of a specific country, both in industrial (EOR installations) and in environmental purposes.

Chosen industrial branches (e.g., ammonia production, hydrogen production) from industrial sector (Industrial Processes category) that emit significant concentrated streams of CO2 may become the first source of carbon dioxide for sequestration by underground storage in the near future, especially in pilot installations.

Acknowledgements

This paper have been written in the frame of Research Project of the State Committee of Scientific Research No. 5 T12B 041 24.