1 Introduction

The development of new engineering techniques promotes the finding of new technologies that increase product quality [1]. Due to their increased consumption, materials have to meet stringent requirements to comply with current ecology principles [2,3]. Toxic substances, such as derivatives of aromatic amines that are potentially carcinogenic, should, therefore, be avoided in commercial production [4–7]. Amino compounds are currently incorporated into polymeric materials to obtain anti-ageing compounds. In the past years, there have been no significant changes in polymer stabilisation methods [8,9]. Most investigations have focused on structural improvements to increase the effectiveness of the Hindered Amine Light Stabilisers (HALS)-type anti-oxidants used [10,11]. In our study, we decided to propose natural anti-oxidants obtained in the form of natural extracts from plants, such as green tea leaves. Green tea leaves are the richest source of various polyphenolic compounds, with up to 36% of these compounds being flavonids [12–14], which are known as strong anti-oxidants [15–18]. Polyphenols can be obtained by standard extraction in an organic solvent or by innovative extraction methods, e.g., in supercritical carbon dioxide [19–21]. The addition of natural anti-oxidants to polymers may eliminate hazardous substances from technological processes (Scheme 1).

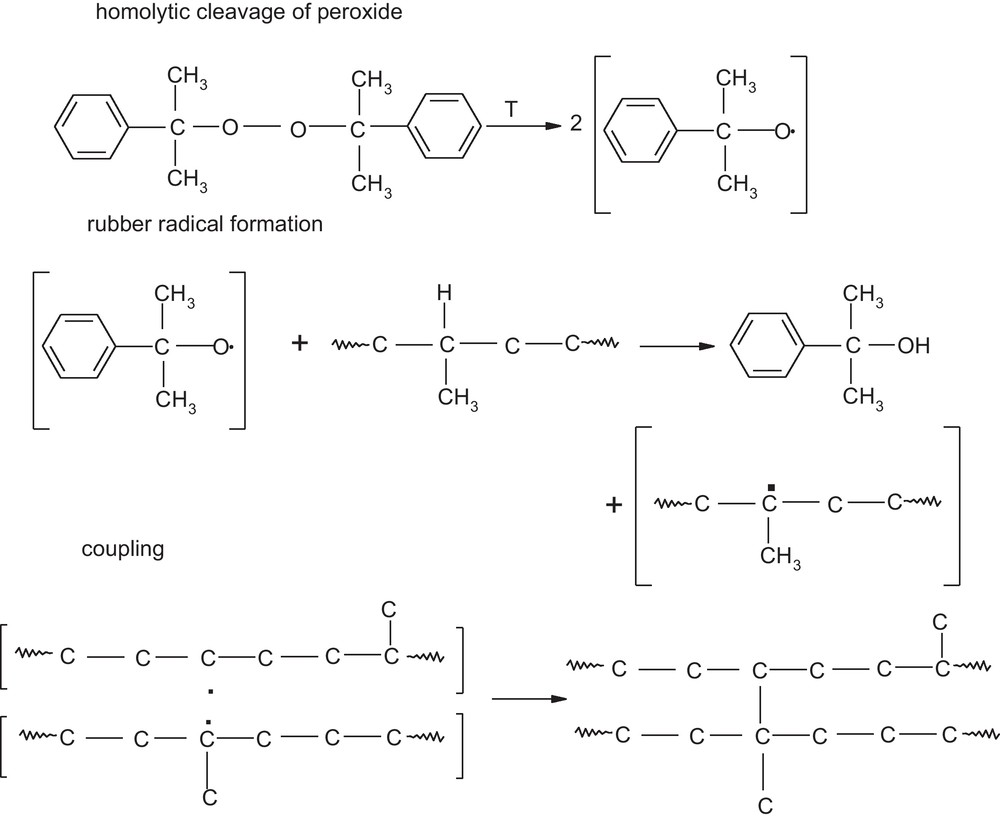

Mechanism of polymer degradation.

2 Materials and methods

2.1 Reagents

The object of this study was ethylene-propylene rubber (EPM, Dutral CO-054, manufacturer: Montedison Ferrara–Italy). Dicumyl peroxide (DCP; Fluka), 1,3,5-Triallyl-1,3,5-triazine-2,4,6 (Sigma Aldrich Chemie GmbH), hexadecyltrimethylammonium bromide (CTBA; Sigma Aldrich Chemie GmbH), and Areosil 380 silica (Degussa) were used as a cross-linking agent, a cross-linking co-agent, a dispersing agent, and a filler, respectively.

Extracts from green teas were used as anti-ageing substances. More specifically, dried leaves of Chinese Sencha (S) and Gun Powder (GP), which were purchased from Natur-Vit, Poland, were used. The anti-oxidant properties of their extracts were compared with that of a commonly used hydroxybenzophenone UV stabiliser, Chimassorb81 (commercial-type anti-oxidant [Ciba]). The compositions of the elastomer blends are given in Table 1.

Composition of ethylene-propylene rubbers (EPM) elastomer blends containing extracts of tea.

| Composition | M1 (phr) | M2 (phr) | M3 (phr) | M4 (phr) |

| EPM | 100 | 100 | 100 | 100 |

| DCP | 2.00 | 2.00 | 2.00 | 2.00 |

| CTBA | 2.00 | 2.00 | 2.00 | 2.00 |

| 1,3,5-Triallyl-1,3,5-triazine | 0.5 | 0.5 | 0.5 | 0.5 |

| A380 | 30 | 30 | 30 | 30 |

| Chimassorb81 | 1.25 | |||

| Gun Powder | 1.25 | |||

| Sencha | 1.25 |

2.2 Preparation and measurement methods

The extraction of the green tea leaves was performed in an 80% ethanolic solution using an OMC SER 148 apparatus from Envag consisting of three extraction columns and three containers with thimbles, in which samples of disintegrated and dried tea leaves were placed. The process was carried out for 6 h at the boiling point of ethanol, 78.5 °C.

Rubber blends were prepared using a laboratory mixing mill with rolls of the following dimensions: length L = 330 mm, diameter D = 140 mm. The speed of rotation the front roll was Vp = 20 rpm, the friction was 1.1, and the average temperature of the rolls was of about 40 °C.

The vulcanization of rubber blends was carried out using steel vulcanization molds placed between the plates of an electrically heated hydraulic press. Teflon films were used as spacers to prevent adherence of the blends to the press plates. Samples were vulcanised for 30 min at a temperature of 160 °C and under a pressure of 15 MPa. The vulcanization process of EPM rubber followed according to Scheme 2.The density of crosslinks in the vulcanizates was determined by the method of equilibrium swelling. More specifically, the vulcanizates were subjected to equilibrium swelling in toluene for 48 h at room temperature. The swollen samples were then weighed on a torsion balance and dried to a constant weight in a dryer at a temperature of 60 °C; they were reweighed after 48 h. The cross-linking density was determined using the Flory-Rehner's equation:

| (1) |

Vulcanization process of ethylene-propylene rubber with dicumyl peroxide.

The tensile strength (TS) of the vulcanizates was tested according to the standard method described in PN-ISO 37:1998 using a ZWICK tester (model 1435) and a w-3 dumbbell. Ageing characteristics were determined according to the standard method described in PN-82/C-04216. More specifically, samples were subjected to the action of air at an elevated temperature (353 K) for 7 days in a dryer with thermo-circulation. UV ageing was performed using an UV 2000 apparatus from Atlas. The measurements lasted for 120 h and involved repetition of consecutive day and night segments with the following parameters: day segment (radiation intensity: 0.7 W m−2, temperature: 60 °C, duration: 8 h), night segment (no UV radiation, temperature: 50 °C, duration: 4 h). Climatic ageing was carried out using a Weather-Ometer (Atlas; Ci4000). The test was based on two variable segments simulating day and night conditions, and the samples were subjected to two different cycles of thermal shocks. During the first cycle, they were subjected to a temperature of 120 °C for 10 min, and during the second cycle, they were kept at a temperature of −50 °C for 10 min. The whole ageing process consisted of 450 cycles. The ageing coefficient S was calculated according to the relationship: S = [TSA × EbA]/[TSB × EbB], where TS corresponds to the tensile strength; Eb to the elongation at break; and TSA and EbA correspond to the values of the TS and elongation at break after ageing, respectively. The color of the vulcanizates obtained was measured by means of a CM-3600d spectrophotometer. The radiation source consisted of four impulses of xenon tubes. The spectral range of the apparatus was 360–740 nm, where the change of color ΔE was calculated by the equation:

| (2) |

3 Results and discussion

3.1 Effect of green tea extracts on the cross-linking density of ethylene-propylene rubbers (EPM) vulcanizates

The addition of a Ciba increases the network density of EPM vulcanizates to 7.32 × 10−5 mol cm−3. On the other hand, extracts of S and GP teas influence the value of ve to a lesser extent; the differences amount to about 10% and are within the measurement error limits.

UV radiation on a standard sample containing no anti-oxidant results in its degradation as indicated by a decreased cross-linking density. The thermal ageing of most of the vulcanizates tested increases their cross-linking. The highest increase, which is about 52.4%, is observed in the case of a standard sample. The EPM vulcanizate exclusively containing an S extract is characterised by an insignificant decrease in cross-linking. Ageing performed under simulated weather conditions causes small changes in the network density of samples containing green tea extracts, whereas in the case of a standard EPM sample, its cross-linking is increased by 37% to a value of 8.38 × 10−5 mol cm−3 (Table 2).

Effect of extracts of green tea on the cross-linking density of ethylene-propylene rubbers (EPM) vulcanizates.

| Vulcanizates | ν(t) × 105(mol dm−3) Before | ν(t) × 105 (mol dm−3) After UV | ν(t) × 105 (mol dm−3) After thermal | ν(t) × 105 (mol dm−3) After weathering |

| EPM | 6.10 | 2.92 | 9.30 | 8.38 |

| EPM/chimassorb81 | 7.32 | 6.63 | 6.81 | 6.28 |

| EPM/Gun Powder | 5.87 | 6.35 | 6.43 | 5.83 |

| EPM/Sencha | 6.71 | 6.12 | 6.24 | 6.49 |

3.2 Effect of green tea extracts on the mechanical properties of ethylene-propylene rubbers (EPM) vulcanizates before and after ageing

The lowest TS of 16.7 MPa was observed for the vulcanizate sample containing the extract obtained from S leaves. Compared to a standard vulcanizate, no significant changes in the mechanical properties were observed when a GP tea extract was added. A minimal value of elongation at break (Eb) of 581% was observed in the case of the vulcanizate containing Chimassorb 81, whereas the Eb values of the remaining vulcanizates were comparable with that of the standard sample (Table 3).

Effect of extracts of green tea on the tensile strength of ethylene-propylene rubbers (EPM) vulcanizates.

| Vulcanizates | SE300 (MPa) | TS (MPa) | Eb (%) |

| EPM | 3.30 | 21.10 | 623 |

| EPM/chimassorb81 | 3.17 | 19.40 | 581 |

| EPM/Gun Powder | 2.81 | 20.80 | 645 |

| EPM/Sencha | 3.08 | 16.70 | 617 |

Ageing coefficients calculated on the basis of changes in the deformation energy indicate the degree of degradation or additional cross-linking of the samples tested. Indeed, the lesser the degradation, the closer the ageing coefficient value is to 1. UV radiation leads to considerable changes in the mechanical properties of the standard sample, whose TS is decreased by 60%.

By contrast, the vulcanizate containing the GP extract displays a TS decrease of 58%. A similar result was observed in the case of the vulcanizate containing the S extract (UV ageing coefficient of 0.94). Thus, the anti-oxidants used in this study show little ability in protecting against UV radiation, compared to the commercial stabiliser Chemiassorb81 (UV ageing coefficient of 0.83) (Table 4). Although climatic factors do not really affect the properties of vulcanizates containing a mixture of natural anti-oxidants, they affect the properties of the standard sample as evidenced by a high degree of degradation (0.45). The smallest change in deformation energy was observed for the vulcanizate containing Chemiassorb 81 (weather ageing coefficient of 0.99) and by the vulcanizate containing the S extract (weather ageing coefficient: 0.94); in both cases, the TS remains unchanged (Table 5). Heating the samples at a temperature of 70°C for 7 days results in additional cross-linking in all vulcanizates as shown by the increased TS and by the fact that the values for the thermal ageing coefficients exceed 1 (Table 6).

Mechanical properties of ethylene-propylene rubbers (EPM) vulcanizates of extracts of green tea, subjected to UV ageing.

| Vulcanizates | SE300 (MPa) | TS (MPa) | Eb (%) | TSA/TSBA | EbA/EbB | (TS × Eb)A./(TS × Eb)B |

| After UV ageing | ||||||

| EPM | 7.19 | 8.37 | 338 | 0.39 | 0.54 | 0.22 |

| EPM/chimassorb81 | 3.67 | 16.20 | 577 | 0.83 | 0.99 | 0.83 |

| EPM/Gun Powder | 4.20 | 8.07 | 522 | 0.39 | 0.81 | 0.31 |

| EPM/Sencha | 3.42 | 16.50 | 590 | 0.99 | 0.96 | 0.94 |

Mechanical properties of the ethylene-propylene rubbers (EPM) vulcanizates containing of extracts of green tea subjected to weathering.

| Vulcanizates | SE300 (MPa) | TS (MPa) | Eb (%) | TSA/TSB | EbA/EbB | (TS × Eb)A./(TS × Eb)B |

| After weathering | ||||||

| EPM | 6.61 | 13.50 | 435 | 0.63 | 0.70 | 0.45 |

| EPM/chimassorb81 | 3.76 | 19.20 | 583 | 0.99 | 1.00 | 0.99 |

| EPM/Gun Powder | 3.38 | 19.30 | 589 | 0.93 | 0.91 | 0.85 |

| EPM/Sencha | 3.42 | 16.50 | 590 | 0.99 | 0.96 | 0.94 |

Mechanical properties of the ethylene-propylene rubbers (EPM) vulcanizates containing of extracts of green teas subjected to thermal ageing.

| Vulcanizates | SE300 (MPa) | TS (MPa) | Eb (%) | TSA/TSB | EbA/EbB | (TS × Eb)A/(TS × Eb)B |

| After thermal | ||||||

| EPM | 4.44 | 22.40 | 617 | 0.94 | 0.99 | 1.05 |

| EPM/chimassorb81 | 2.97 | 17.4 | 790 | 0.90 | 1.36 | 1.22 |

| EPM/Gun Powder | 3.73 | 21.70 | 670 | 1.04 | 1.03 | 1.08 |

| EPM/Sencha | 3.81 | 17.90 | 602 | 1.07 | 0.97 | 1.05 |

3.3 Changes in colour of the vulcanizates containing green tea extracts caused by the actions of heat, humidity and radiation

The addition of tea extracts to EPM vulcanizates changes their colour due to the presence of polyphenols and chlorophyll in the green tea leaves. As a result, the changes in colour under the influence of ageing are the greatest in those samples. These colour changes result from the oxidation of polyphenols or chlorophyll, which is influenced by degrading factors. The basic parameter determining the change in colour of a sample subjected to ageing is the differential of the product of a and b parameters (dE × ab), where a and b are the coordinates on the colour axis. Among all samples, the vulcanizate containing the GP extract was the most affected in terms of colour change by climatic ageing; its dE × ab coefficient was as high as 23.48 and was the highest among all vulcanizates subjected to ageing. UV ageing of the S tea-containing sample also resulted in a considerable change in colour (dE × ab = 13.71). On the other hand, thermo-oxidative ageing has the smallest effect on the colour of the vulcanizate compared to the other parameters tested (Table 7).

Color parameters of ethylene-propylene rubbers (EPM) vulcanizates containing of extracts of green tea after UV ageing.

| Vulcanizates | ΔE × ab | ΔE × ab | ΔE × ab |

| After thermal ageing | After UV ageing | After weathering | |

| EPM | 4.84 | 10.63 | 8.09 |

| EPM/chimassorb81 | 4.33 | 7.47 | 2.34 |

| EPM/Gun Powder | 3.99 | 4.04 | 23.48 |

| EPM/Sencha | 0.54 | 13.71 | 13.12 |

4 Conclusion

EPM vulcanizates containing green tea extracts display good protective properties against the negative synergetic action of climatic factors, such as moisture, sonar radiation, elevated temperature, or precipitation. The extracts that were tested (and it will be characterised in a separate study) are able to scavenge free radicals and impede oxidation processes. The protective action of these extracts in elastomers is comparable to that of a commercial stabiliser. These results indicate that natural plant extracts could be attractive alternatives to commonly synthetic stabilisers in the future. Improving their dispersion and lability in polymers will also improve their protective properties against concentrated UV radiation.

Acknowledgement

The work was financially supported from research project No. N N209 450639 and No. N N209 088038.