1 Introduction

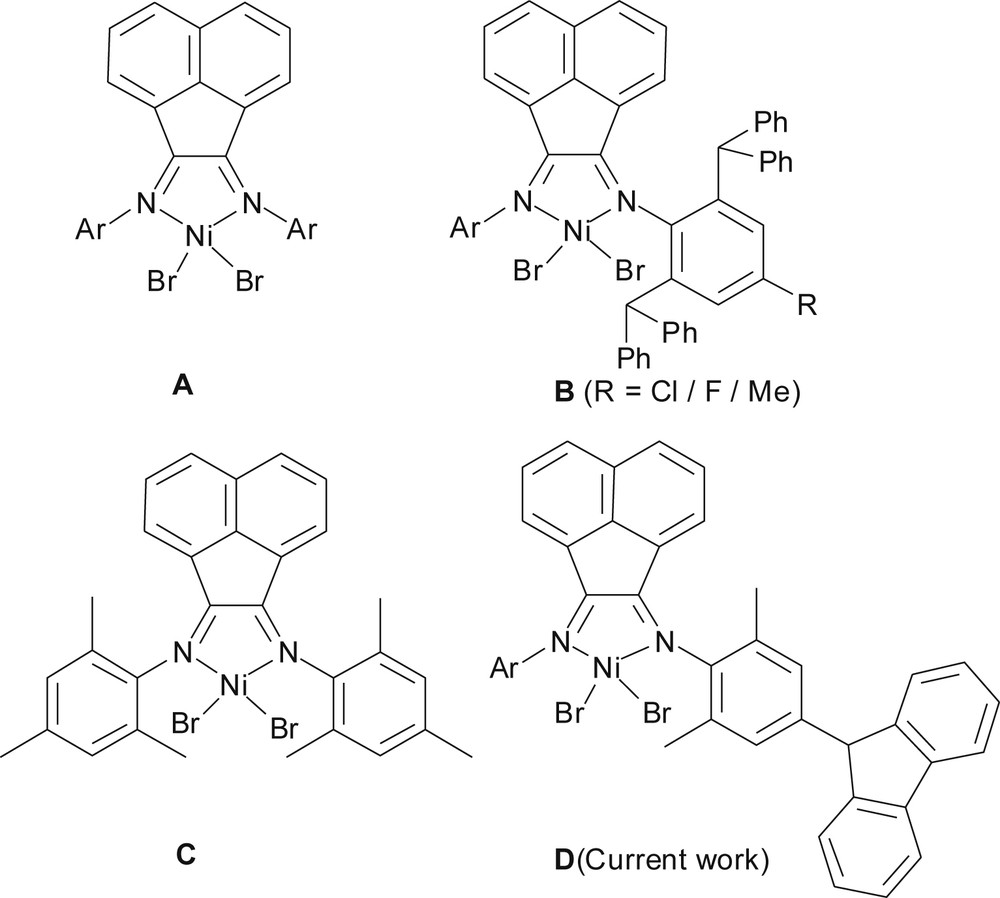

The design of effective late-transition metal pre-catalysts for ethylene reactivity (polymerization vs. oligomerization) has been the subject of extensive exploration for twenty years or so [1]. The discovery of highly active α-diiminonickel complexes [2] (A, Scheme 1) resurrected the use of nickel as the metal centre following the pioneering SHOP process for ethylene oligomerization [3]. To enhance the catalytic performances of nickel-based pre-catalysts, two approaches have been followed: the fine tuning of existing ligand types [4,5] and the design of alternative ligand sets [6,7]. The most promising pre-catalysts identified for a commercial process are those based on 1,2-bis(arylimino)acenaphthylnickel precursors (B, Scheme 1) [5], which exhibit high productivities and thermal stability. Moreover, the unique properties displayed by the resultant polyethylenes make these novel elastomeric materials worthy of note [8]. Among the reports dealing with ligand modifications [1,4,5], few have explored the influence of remote substituents [9], such as fluorenyl groups. Of these reports, most have focused on the effect of remote methyl substituents (e.g. on the para-position of N-aryl group) within late-transition metal complexes (C, Scheme 1) [10] due, in large part, to the availability of the anilines (with and without para-methyl substituents) involved in the ligand synthesis. To further investigate the influence of remote substituents, the 2,6-dimethyl-4-fluorenylphenylamine is designed and used to prepare 1-(2,6-dimethyl-4-fluorenylphenylimino)-2-aryliminoacenaphthylene derivatives and their nickel complexes (D, Scheme 1).

The variation of 1,2-bis(arylimino)acenaphthylylnickel pre-catalysts.

2 Results and discussion

2.1 Synthesis and characterization of 1-(2,6-dimethyl-4-fluorenylphenylimino)-2-aryliminoacenaphthylene derivatives (L1–L5) and their nickel bromide complexes (D1–D5)

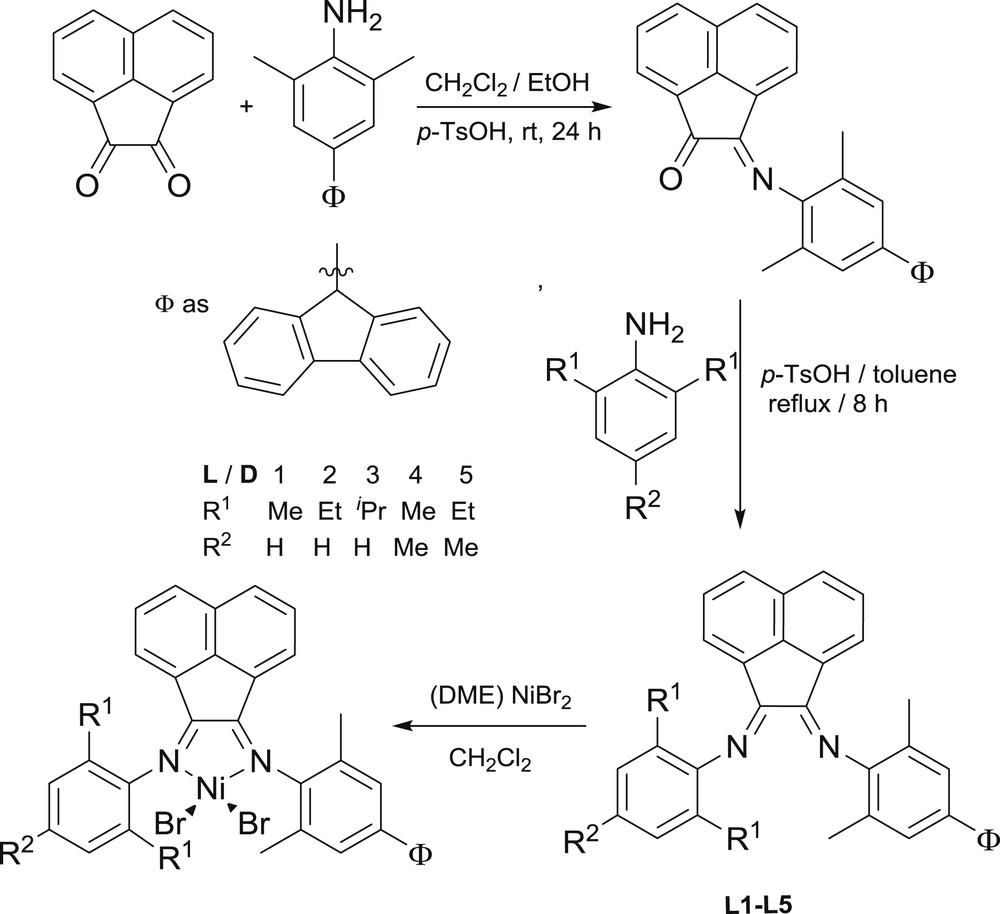

According to a previous report [5], 2-(2,6-dimethyl-4-fluorenylphenylimino)acenaphthylenone can be prepared by the stoichiometric condensation of acenaphtylene-1,2-dione with 2,6-dimethyl-4-fluorenylphenylamine. We have found that this compound can undergo further reactions with various anilines to form the corresponding 1-(2,6-dimethyl-4-fluorenylphenylimino)-2-aryliminoacenaphthylene derivatives (L1–L5, Scheme 2) in reasonable yields, respectively. These compounds were characterized by the FT-IR spectra, NMR spectroscopy and elemental analyses. Treatment of L1–L5 with (DME)NiBr2 in dichloromethane produces the corresponding nickel(II) bromide complexes D1–D5 (Scheme 2) in good yields, which were characterized by FT-IR spectroscopy and elemental analyses.

Synthesis of ligands L1–L5 and their nickel complexes D1–D5.

With regard to the FT-IR spectra, the nickel bromide complexes D1–D5 showed CN stretching vibrations in the range of 1652 cm−1–1609 cm−1, which are at lower frequencies to those observed in the for free L1–L5 (1677 cm−1–1636 cm−1) and of weaker intensity. This suggests effective coordination between Nimino atom and the nickel centre. In addition, the molecular structure of representative D5 was determined by single-crystal X-ray diffraction.

2.2 X-ray crystallographic study

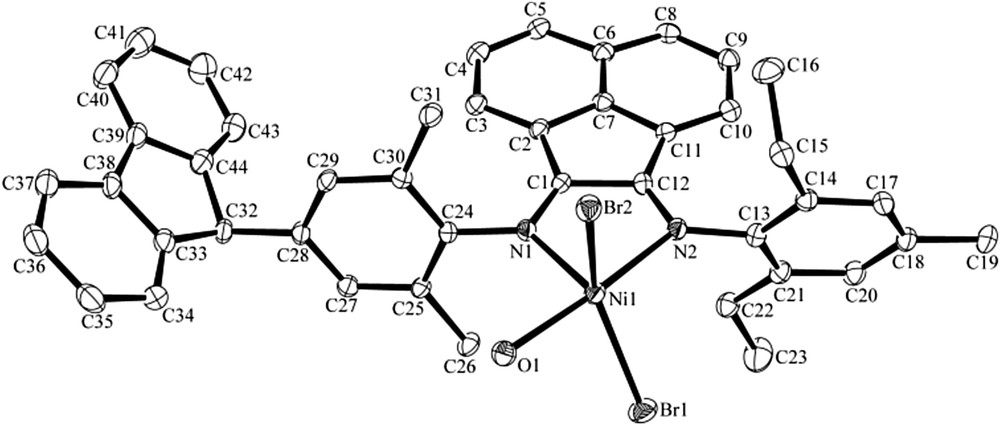

Crystals suitable for the X-ray crystallographic study were grown by layering a chloroform solution of D5 with diethyl ether. Complex D5 exhibits as distorted trigonal bipyramidal geometry around the nickel center, consisting of two nitrogen atoms (N1 and N2), two bromides and an oxygen of the coordinated water molecule. The molecular structure of complex D5 is shown in Fig. 1, and selected bond lengths and angles are given in Table 1. The bond length of Ni1–N1 (2.050(3) Å) is slightly shorter than the corresponding value of the Ni1–N2 (2.175(3) Å). The plane composed of N1, N2, and Ni1 forms the dihedral angles of 81.03° with the N1-aryl ring and 77.04° with the N2-aryl ring, respectively.

Molecular structure of D5·H2O. Thermal ellipsoids are drawn at the 30% probability level. Hydrogen atoms and the molecule of diethyl ether are omitted for clarity.

Selected bond lengths (Å) and angles (°) for complex D5.

| Bond lengths (Å) | |

| Ni(1)–N(1) | 2.050 (3) |

| Ni(1)–N(2) | 2.175 (3) |

| O(1)–Ni(1) | 2.066 (3) |

| Br(1)–Ni(1) | 2.4295 (9) |

| Br(2)–Ni(1) | 2.4211 (9) |

| C(1)–N(1) | 1.285 (5) |

| C(24)–N(1) | 1.440 (5) |

| C(12)–N(2) | 1.288 (5) |

| C(13)–N(2) | 1.452 (5) |

| Bond angles(°) | |

| Br1–Ni(1)–Br2 | 142.95 (3) |

| N(1)–Ni(1)–O(1) | 92.77 (13) |

| N(1)–Ni(1)–N(2) | 80.50 (13) |

| O(1)–Ni(1)–N(2) | 172.61 (13) |

| Br(2)–N(1)–Ni(1) | 120.90 (9) |

| Br(2)–O(1)–Ni(1) | 87.65 (9) |

| Br(2)–N(2)–Ni(1) | 93.17 (9) |

| Br(1)–N(1)–Ni(1) | 95.98 (9) |

| Br(1)–Ni(1)–O(1) | 96.56 (9) |

| Br(1)–N(2)–Ni(1) | 96.56 (9) |

| C(1)–N(1)–Ni(1) | 113.3 (3) |

| C(12)–N(2)–Ni(1) | 109.0 (2) |

2.3 Ethylene polymerization

Complex D4 was investigated as a pre-catalyst with various alkylaluminum reagents such as methylaluminoxane (MAO), modified methylaluminoxane (MMAO), ethylaluminum sesquichloride (EASC), diethylaluminium chloride (Et2AlCl) and dimethylaluminium chloride (Me2AlCl) at 20 °C under 10 atm ethylene pressure; the results of the evaluation are collected in Table 2. High activities for ethylene polymerization were achieved for all co-catalysts screened. Of the two classes of co-catalysts, methylaluminoxanes and alkylaluminium chlorides, the systems involving EASC or MAO showed the higher activities. Therefore the optimum conditions were determined using the catalytic system of comprised of D4 with EASC or MAO, and the extensive investigations were conducted with all title complexes.

Ethylene polymerization by complex D4 with various co-catalystsa.

| Entry | Cocat. | Al/Ni | Yield/g | Act.b | Mwc | Mw/Mnc | Tmd/°C |

| 1 | MAO | 2000 | 4.40 | 4.40 | 2.69 | 2.05 | 123.9 |

| 2 | MMAO | 2000 | 1.34 | 1.34 | 2.18 | 1.73 | 131.7 |

| 3 | EASC | 400 | 8.41 | 8.41 | 1.64 | 3.11 | 124.1 |

| 4 | Et2AlCl | 400 | 4.31 | 4.31 | 2.38 | 2.43 | 126.9 |

| 5 | Me2AlCl | 400 | 3.96 | 3.96 | 1.98 | 2.57 | 127.8 |

a Conditions: 2 μmol of Ni; 100 mL of toluene; 10 atm of ethylene; 20 °C; 30 min.

b 106 g of PE (mol of Ni)−1 h−1.

c Determined by GPC and Mw: 105 g mol−1.

d Determined by DSC.

2.3.1 Ethylene polymerization by complexes D1–D5/EASC system

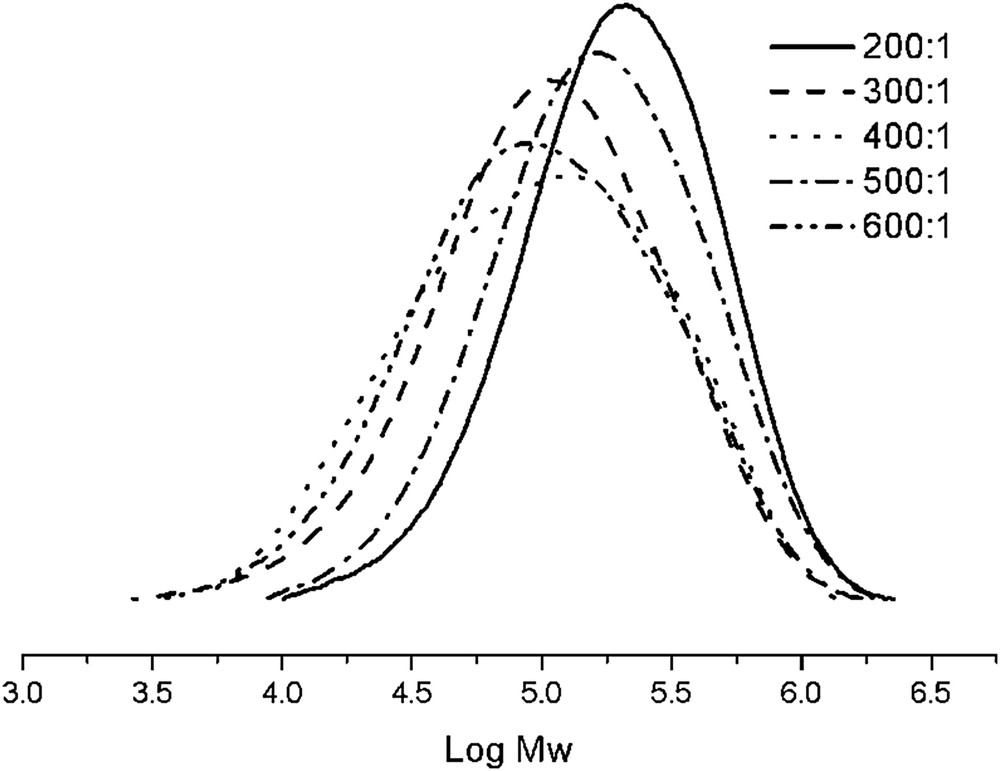

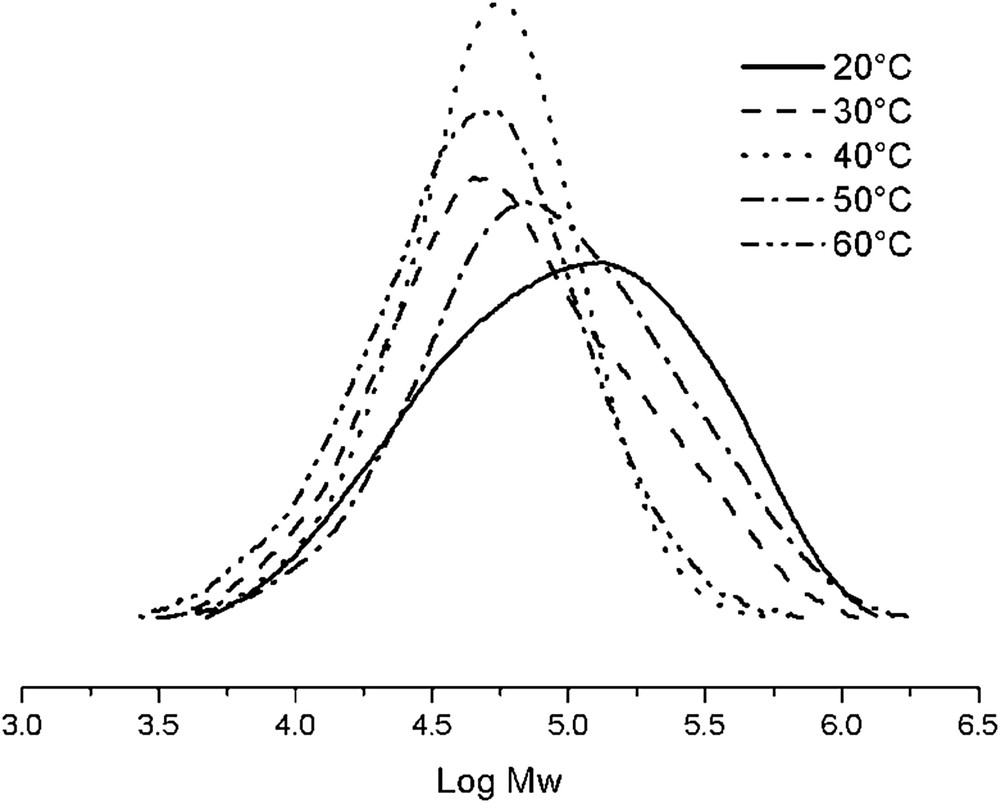

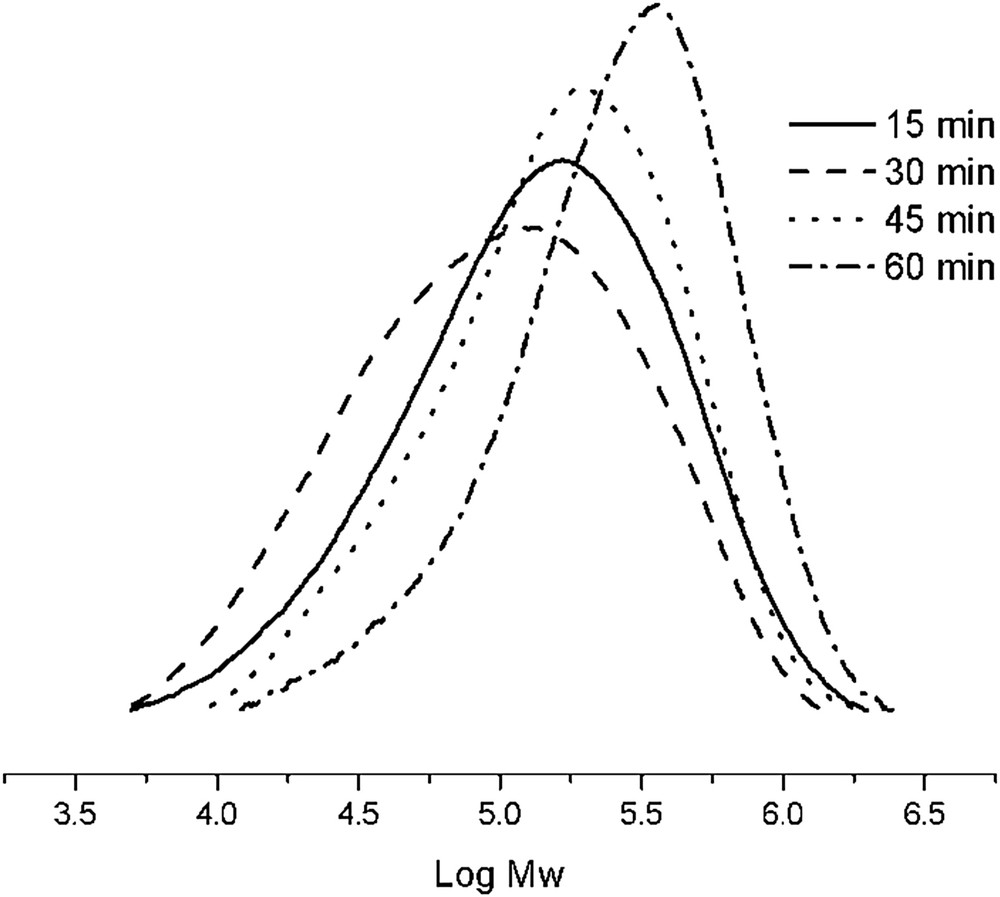

To optimize the catalytic conditions, complex D4 was extensively explored with the reaction parameters such as molar ratios of Al/Ni, reaction temperature and reaction time (Table 3). On increasing the molar ratio of Al/Ni from 200 to 600 (entries 1−5, Table 3), the catalytic activity gradually improved with the Al/Ni ratio between 200 and 400 (entries 1–3, Table 3) showing the best activity as 8.41 × 106 g of PE (mol of Ni)−1 h−1; further increasing the Al/Ni ratio up to 600 (entries 4–5, Table 3) resulted in a slight decrease in the catalytic activity. In general, the polyethylenes obtained exhibited similar molecular weights and narrow polydispersities; their GPC curves are shown in Fig. 2. On increasing the temperature from 20 to 60 °C, significant decreases were observed for the activities from 8.41 to 1.14 × 106 g of PE (mol of Ni)−1 h−1, being caused by both deactivation of the active species and the lower solubility of ethylene at elevated temperatures [5,6]. Indeed, the molecular weights of the resultant polyethylenes showed no clear trend (Fig. 3).

Ethylene Polymerization by D1–D5/EASC (Et3Al2Cl3)a.

| Entry | Pre-cat. | T/°C | t/min | Al/Ni | Yield/g | Act.b | Mwc | Mw/Mnc | Tmd/°C |

| 1 | D4 | 20 | 30 | 200 | 1.23 | 1.23 | 2.72 | 2.06 | 126.7 |

| 2 | D4 | 20 | 30 | 300 | 5.24 | 5.24 | 1.65 | 2.67 | 121.3 |

| 3 | D4 | 20 | 30 | 400 | 8.41 | 8.41 | 1.64 | 3.11 | 124.1 |

| 4 | D4 | 20 | 30 | 500 | 6.21 | 6.21 | 2.37 | 2.26 | 123.6 |

| 5 | D4 | 20 | 30 | 600 | 5.70 | 5.70 | 1.62 | 2.94 | 122.1 |

| 6 | D4 | 30 | 30 | 400 | 4.81 | 4.81 | 0.93 | 2.93 | 120.3 |

| 7 | D4 | 40 | 30 | 400 | 3.62 | 3.62 | 0.59 | 1.97 | 102.3 |

| 8 | D4 | 50 | 30 | 400 | 2.38 | 2.38 | 1.42 | 3.19 | 129.4 |

| 9 | D4 | 60 | 30 | 400 | 1.14 | 1.14 | 0.63 | 1.93 | 129.2 |

| 10 | D4 | 20 | 15 | 400 | 4.91 | 9.82 | 2.21 | 2.90 | 125.5 |

| 11 | D4 | 20 | 45 | 400 | 9.48 | 6.32 | 2.43 | 2.68 | 125.2 |

| 12 | D4 | 20 | 60 | 400 | 9.68 | 4.84 | 4.24 | 2.22 | 112.0 |

| 13 | D1 | 20 | 30 | 400 | 4.21 | 4.21 | 2.30 | 3.41 | 124.5 |

| 14 | D2 | 20 | 30 | 400 | 4.31 | 4.31 | 3.18 | 3.01 | 118.4 |

| 15 | D3 | 20 | 30 | 400 | 3.32 | 3.32 | 3.26 | 2.23 | 116.7 |

| 16 | D5 | 20 | 30 | 400 | 3.84 | 3.84 | 2.91 | 2.70 | 108.8 |

a Conditions: 2 μmol of Ni; 100 mL of toulene, 10 atm of ethylene.

b 106 g of PE (mol of Ni)−1 h−1.

c Determined by GPC and Mw: 105 g mol−1.

d Determined by DSC.

GPC curves of the polyethylene obtained by D4/EASC at different Al/Ni ratios (entries 1−5 in Table 3).

GPC curves of the polyethylene obtained by D4/EASC at different temperatures (entries 3 and 6−9 in Table 3).

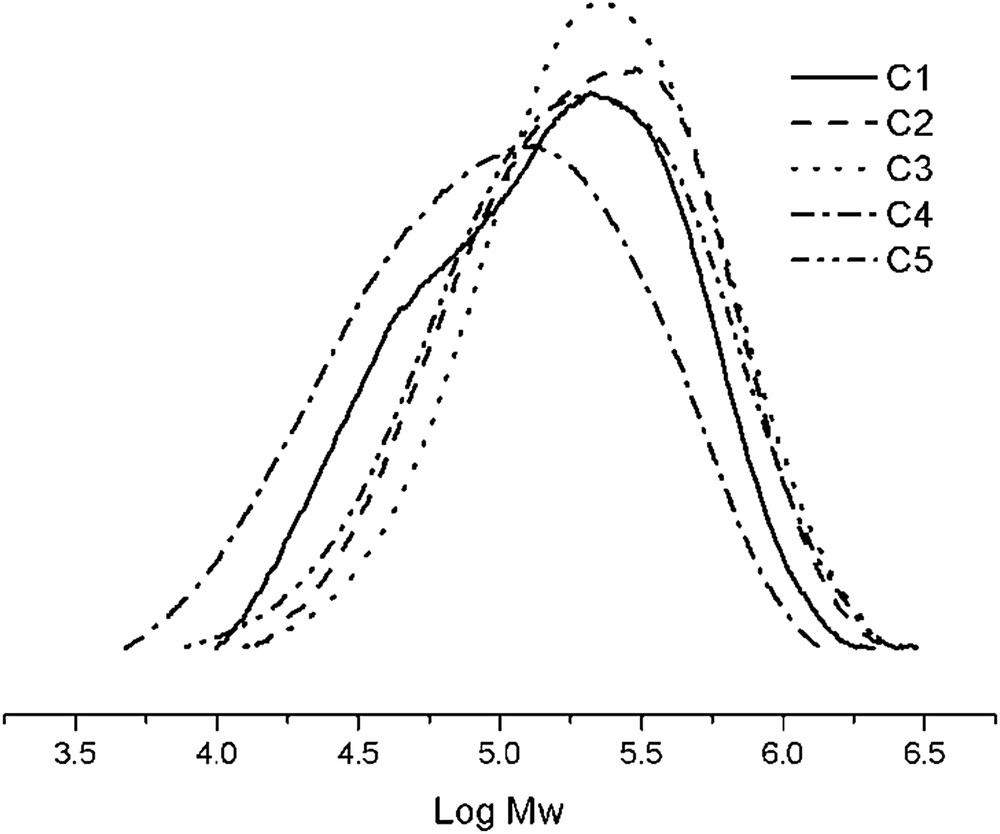

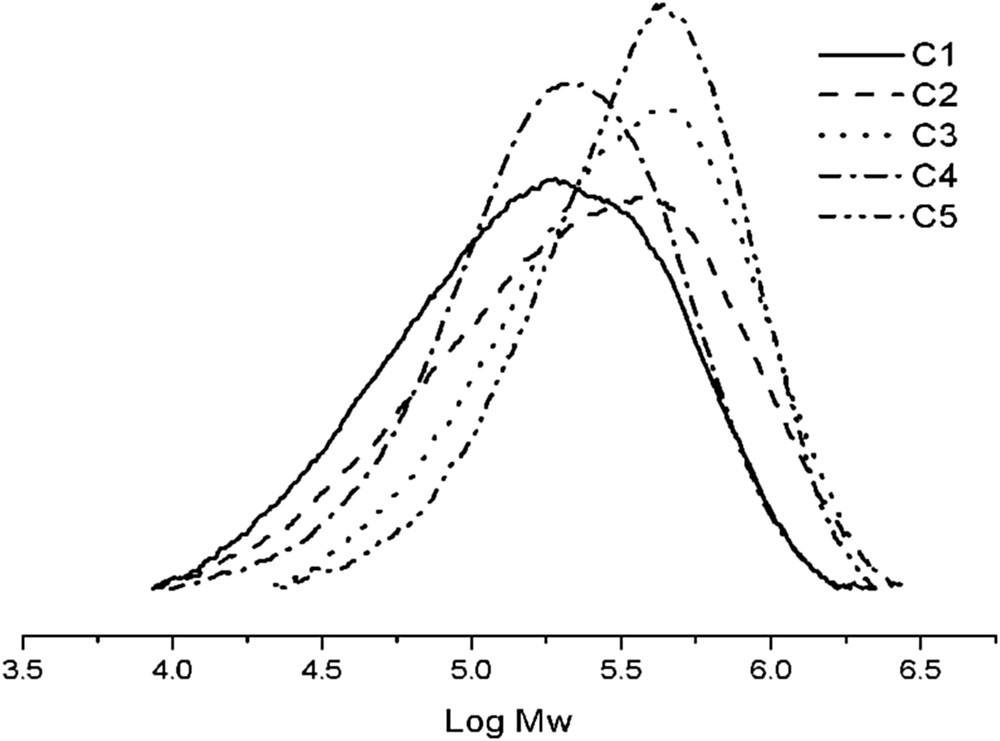

Regarding the lifetime of active species, the polymerizations by the D4/EASC system was conducted over different times from 15 to 60 min (entries 3 and 10−12, Table 3). The highest activity was observed with 15 min (entry 10, Table 3); the longer reaction times used, the lower activities observed, indicating the possible decay of the active species. It is worth mentioning that good activity was still maintained at 60 min, this being consistent with the stability seen for aryliminoacenaphthylnickel analogs [5]. The GPC curves of the polyethylenes are shown in Fig. 4. Subsequently, all nickel complexes (D1–D5) were investigated under the optimum conditions of Al/Ni molar ratio of 400 at 20 °C under 10 atm ethylene pressure (entries 3 and 13−16, Table 3). According to the observations (entries 13−16, Table 3), the polymerization activity decreased in the order of D4 [2,4,6-tri(Me)] > D2 [2,6-di(Et)] > D1 [2,6-di(Me)] > D5 [2,6-di(Et)-4-Me] > D3 [2,6-di(i-Pr)]. Their molecular weights of the polyethylenes gradually increased as the steric bulk of the substituents of the ortho-position of aryl of the ligands increases, which is ascribed to bulky substituents retarding chain transfer and increasing chain growth; the GPC curves of the obtained polyethylenes are shown in Fig. 5.

GPC curves of the polyethylene obtained by D4/EASC over different times (entries 3 and 10−12 in Table 3).

GPC curves of the polyethylene obtained by D1–D5/EASC (entries 3 and 13−16 in Table 3).

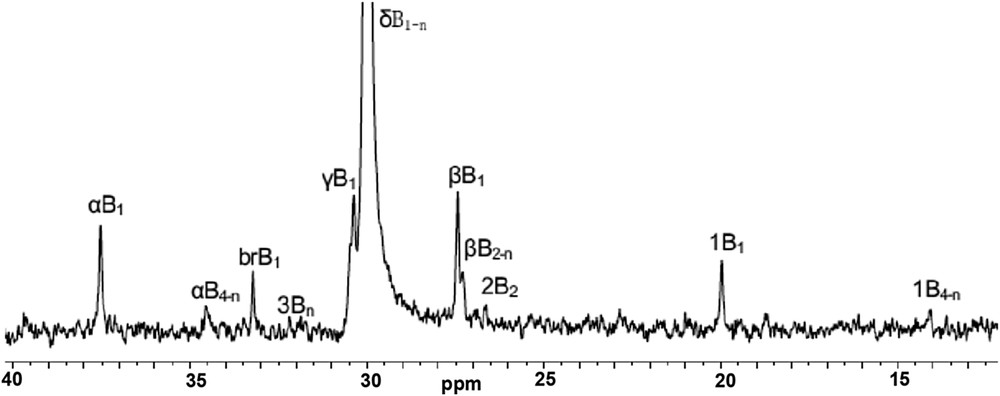

In comparison to results determined using related systems [5], the obtained polyethylenes herein possessed higher molecular weights. Moreover, their Tm values were relatively higher, indicating the possibility of fewer branches. To confirm this point, the 13C NMR spectrum of the polyethylene obtained using D4/EASC at 40 °C (entry 7, Table 3) was measured at elevated temperature (Fig. 6). The spectrum indicated 39 branches/1000 carbons, in which the branches included methyl (45.5%), butyl (10.6%), amyl (12.9%) and long branches (31.0%).

13C NMR spectrum of the obtain polyethylene by D4/EASC at 40 °C (entry 7, Table 3).

2.3.2 Ethylene polymerization with D1–D5/MAO system

Using MAO as co-catalyst, the optimization of the reaction parameters was conducted with complex D4; the results are collected in Table 4. On increasing the Al/Ni ratio from 1000 to 2000 (entries 1−3, Table 4), the catalytic activities increased, as did the molecular weights of the resultant polyethylenes (from 1.70 to 2.69 × 105 g mol−1) while the polydispersity narrowed from 3.17 to 2.05. On increasing the Al/Ni ratio further to 2500 and 3000 (entries 4 and 5, Table 4), the activity became lower and produced polyethylene with lower molecular weight. The GPC curves of the obtained polyethylenes are shown in Fig. 7.

Ethylene polymerization by D1–D5/MAOa.

| Entry | Pre-cat. | T/°C | t/min | Al/Ni | Yield/g | Act.b | Mwc | Mw/Mnc | Tmd/°C |

| 1 | D4 | 20 | 30 | 1000 | 2.41 | 2.41 | 1.70 | 3.17 | 117.1 |

| 2 | D4 | 20 | 30 | 1500 | 3.24 | 3.24 | 2.53 | 2.91 | 126.6 |

| 3 | D4 | 20 | 30 | 2000 | 4.40 | 4.40 | 2.69 | 2.05 | 123.9 |

| 4 | D4 | 20 | 30 | 2500 | 3.50 | 3.50 | 2.35 | 3.00 | 125.4 |

| 5 | D4 | 20 | 30 | 3000 | 2.86 | 2.86 | 2.17 | 3.13 | 122.6 |

| 6 | D4 | 30 | 30 | 2000 | 2.72 | 2.72 | 4.14 | 2.19 | 120.8 |

| 7 | D4 | 40 | 30 | 2000 | 2.54 | 2.54 | 1.09 | 2.13 | 119.2 |

| 8 | D4 | 50 | 30 | 2000 | 1.21 | 1.21 | 0.61 | 2.04 | 114.8 |

| 10 | D4 | 20 | 15 | 2000 | 2.76 | 5.52 | 2.42 | 2.40 | 129.8 |

| 11 | D4 | 20 | 45 | 2000 | 4.88 | 3.25 | 2.52 | 1.85 | 130.5 |

| 12 | D4 | 20 | 60 | 2000 | 5.08 | 2.54 | 2.97 | 2.89 | 122.5 |

| 13 | D1 | 20 | 30 | 2000 | 2.88 | 2.88 | 2.55 | 2.84 | 121.4 |

| 14 | D2 | 20 | 30 | 2000 | 3.64 | 3.64 | 3.71 | 2.99 | 119.7 |

| 15 | D3 | 20 | 30 | 2000 | 1.83 | 1.83 | 4.45 | 2.12 | 123.7 |

| 16 | D5 | 20 | 30 | 2000 | 1.97 | 1.97 | 5.33 | 1.93 | 129.7 |

a Conditions: 2 μmol of Ni; 100 mL of toulene, 10 atm of ethylene.

b 106 g of PE (mol of Ni)−1 h−1.

c Determined by GPC and Mw: 105 g mol−1.

d Determined by DSC.

GPC curves of the polyethylene obtained by D4/MAO at different Al/Ni ratios (entries 1−5, Table 4).

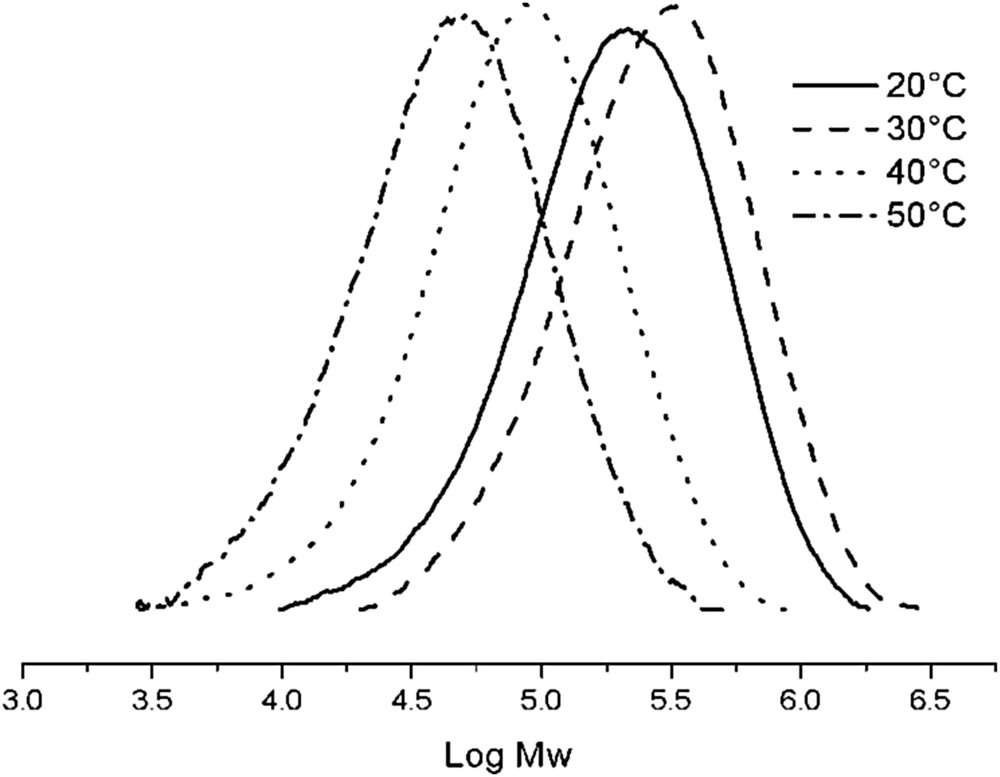

Changing the reaction temperature from 20 °C to 50 °C, the activity gradually decreased, this being consistent with observations reported for analogous catalysts [5i,j]; again, the molecular weights of obtained polyethylenes did not show and discernible trend with regard to polymerization temperature (Fig. 8). Within different reaction times (entries 3 and 9−11, Table 4), the highest activity was observed within 15 min (entry 9, Table 4); on longer reaction time, lower activity was observed. Moreover, the molecular weights of obtained polyethylenes were slightly affected by the reaction times (Fig. 9). A more thorough investigation was then performed on complexes (D1–D5) at Al/Ni molar ratio of 2000 and at 20 °C (entries 3 and 13−16). The activity increased in the order of D4 [2,4,6-tri (Me)] > D2 [2,6-di(Et)] > D1 [2,6-di(Me)] > D5 [2,6-di(Et)-4-Me] > D3 [2,6-di(i-Pr)], being consistent with the trend observed with the above systems using EASC. The GPC curves of polyethylenes were produced by catalyst systems D1–D5 are shown in Fig. 10.

GPC curves of the polyethylene obtained by D4/MAO at different temperatures (entries 3 and 6−8, Table 4).

GPC curves of the polyethylene obtained by D4/MAO over different times (entries 3 and 10−12, Table 4).

GPC curves of the polyethylene obtained by D1–D5/MAO (entries 3 and 13–16, Table 4).

In addition, the resultant polyethylenes generally showed the higher Tm values, this being consistent with above system with EASC as co-catalyst. The high-temperature 13C NMR study was carried out on polyethylene obtained using D4/MAO at 50 °C (entry 8, Table 4) and shown in Fig. 11. Based on the literature method [11], 8 branches/1000 carbons could be identified in the spectrum. These nickel complexes bearing para-fluorenyl substituent produced polyethylenes with high molecular weight.

13C NMR spectrum of the obtained polyethylene by D4/MAO at 40 °C (entry 7, Table 4).

With regard to the pre-catalysts shown in Scheme 1, the C-model containing the para-methyl [10] exhibited higher catalytic activities than its analogs A (Scheme 1) [2a]. On the other hand, B-model pre-catalysts with the bulky benzhydryl-substituent [5] enhanced the catalytic activities in comparison with A-model pre-catalysts [2]. Using the bulky para-fluorenyl substituent herein (D, Scheme 1), the current pre-catalysts exhibited high activities up to 9.82 × 106 g of PE (mol of Ni)−1 h−1 and more importantly, the resultant polyethylenes possessed higher molecular weights (5.33 × 105 g mol−1), narrower polydispersity and displayed higher Tm values (up to 130 °C). Hence, these results highlight the need to explore in more detail the effects of tuning a remote substituent on catalytic performance.

3 Conclusions

The series of 1-(2,6-dimethyl-4-fluorenylphenylimino)-2-aryliminoacenaphthylene derivatives (L1–L5) and their nickel complexes (D1–D5) were synthesized and characterized. Because of the presence of the remote fluorenyl substituent, the polyethylenes obtained showed narrow polydispersities, similar molecular weights and lower branching content (due to higher melting points). These nickel complexes showed high activities toward ethylene polymerization and, in addition, the current catalytic systems possessed longer lifetimes. Notably, the Ni/EASC system achieved an activity up to 9.82 × 106 g of PE (mol of Ni)−1 h−1, which would be high for a commercial application.

4 Experimental

4.1 General considerations

Manipulations involving air/moisture sensitive compounds were carried out under N2 atmosphere using a Schlenk line. Toluene was distilled from Na/benzophenone as and when required. Methylaluminoxane (MAO, 1.46 M solution in toluene) and modified methylaluminoxane (MMAO, 1.93 M in heptane, 3A) were purchased from Akzo Nobel Corp. Ethylaluminium sesquichloride (EASC, 0.87 M in toluene), diethylaluminum chloride (AlEt2Cl, 1.17 M in toluene) and dimethylaluminum chloride (AlMe2Cl, 1.00 M in toluene) was purchased from Acros Chemicals. High-purity ethylene was purchased from Beijing Yansan Petrochemical Co. and used as received. Other reagents were purchased from Aldrich, Acros, or local suppliers. (DME)NiBr2 was prepared in our laboratory according to literature procedure [12]. NMR spectra were recorded on a Bruker DMX 400 MHz instrument at ambient temperature using TMS as an internal standard. IR spectra were recorded on a PerkinElmer System 2000 FT-IR spectrometer. Elemental analysis was carried out using a Flash EA 1112 microanalyzer. Molecular weights and molecular weight distributions (MWDs) of polyethylene were determined by a PLGPC220 instrument at 150 °C, with 1,2,4-trichlorobenzene as the solvent. Melting points of polyethylenes were measured from the second scanning run on a PerkinElmer DSC-7 differential scanning calorimetry (DSC) analyzer under a nitrogen atmosphere; in the procedure, a sample of about 3.8–4.5 mg was heated to 180 °C at a rate of 20 °C/min, kept for 5 min at 180 °C to remove the thermal history, and then cooled at a rate of 20 °C/min to −40 °C. 13C NMR spectra of the polyethylenes were recorded on a Bruker DMX-300 MHz instrument at 135 °C in C6D4Cl2 with TMS as an internal standard.

4.2 Synthesis and characterization

4.2.1 Synthesis of nickel complexes L1–L5

2-(4-fluorenyl-2,6-dimethylphenylimino)acenaphthylen-1-one. A mixture of acenapthylen-1,2-dione (7.28 g, 40 mmol), 4-fluorenyl-2,6-dimethylaniline (11.40 g, 40 mmol) was dissolved in CH2Cl2/EtOH (250 mL/5 mL). To this, was added a catalytic amount of p-toluenesulfonic acid and stirred room temperature for 24 h. The solvent was removed using a rotary evaporator to obtain a crude product, which was chromatographed over a basic alumina column using a mixture of ethyl acetate/hexane (v/v = 1:10) as eluent to obtain a red solid. Yield: 9.68 g, 54%. Mp: 218–220 °C. 1H NMR (CDCl3, 400 MHz, ppm): δ 8.17 (d, J = 8.0 Hz, 2H), 8.00 (d, J = 8.0 Hz, 1H), 7.85–7.79 (m, 3H), 7.47–7.33 (m, 7H), 6.89 (s, 2H), 6.64 (d, J = 8.0 Hz, 1H), 5.06 (s, 1H), 1.97 (s, 6H). 13C NMR (CDCl3, 100 MHz, ppm): δ 189.6, 160.4, 148.2, 147.6, 142.9, 141.0, 137.5, 132.1, 131.0, 130.9, 129.4, 128.5, 128.3, 128.2, 127.8, 127.3, 125.3, 125.0, 122.5, 122.2, 119.9, 54.1, 17.9. FT-IR (cm−1): 3389 (w), 3041 (w), 2911 (w), 2168 (w), 1721 (s), 1647 (νCN, s), 1596 (s), 1472 (m), 1441 (s), 1300 (w), 1272 (m), 1218 (m), 1177 (w), 1149 (m), 1096 (w), 1023 (m), 940 (w), 904 (s), 872 (w), 829 (s), 801 (w), 775 (s), 733 (w), 693 (w), 667 (m). Anal. Calcd for C33H23NO (449.55): C, 88.17; H, 5.16; N, 3.12. Found: C, 88.12; H, 5.22; N, 3.18.

4.2.2 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-dimethyl-phenylimino)acenaphthylene (L1)

A mixture of 2-(4-fluorenyl-2,6-dimethylphenylimino)acenaphthylen-1-one (0.90 g, 2.0 mmol) and 2,6-dimethyl aniline (0.36 g, 3.0 mmol) was dissolved in 100 mL of toluene containing a catalytic amount of p-toluenesulfonic acid, which was refluxed for 8 h using a Dean–Stark apparatus. The solvent was evaporated by rotary evaporator to obtain a crude product, which was purified by column chromatography on basic aluminum oxide eluting with ethyl acetate- petroleum ether (v/v = 1:20) to afford product in 0.64 g (58%) isolated yield. Mp: 209–211 °C. 1H NMR (CDCl3, 400 MHz, ppm): δ 7.90–7.84 (m, 4H), 7.49–7.34 (m, 8H), 7.16 (d, J = 8.0 Hz, 2H), 7.07 (t, J = 8.0 Hz, 1H), 6.90 (s, 2H), 6.80 (d, J = 4.0 Hz, 1H), 6.62 (d, J = 8.0 Hz, 1H), 5.08 (s, 1H), 2.13 (s, 6H), 2.06 (s, 6H). 13C NMR (CDCl3, 100 MHz, ppm): δ 161.3, 160.8, 149.3, 148.4, 148.3, 141.0, 136.7, 131.1, 129.6, 129.5, 129.0, 128.9, 128.3, 127.3, 127.2, 125.4, 125.2, 124.8, 124.7, 123.8, 123.7, 123.4, 122.5, 121.7, 119.9, 118.8, 54.2, 22.7, 17.8. FT-IR (cm−1): 2968 (w), 2910 (w), 2361 (m), 2335 (w), 1668 (νCN, w), 1637 (νCN, m), 1592 (s), 1470 (s), 1438 (s), 1376 (w), 1275 (m), 1231 (m), 1204 (m), 1145 (w), 1084 (m), 1029 (s), 922 (s), 828 (s), 774 (m), 736 (s), 698 (w), 670 (m). Anal. calcd for C41H32N2 (552.72): C, 89.10; H, 5.84; N, 5.07. Found: 89.18; H, 5.91; N, 4.92.

4.2.3 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-diethyl-phenylimino)acenaphthylene (L2)

Using the similar procedure as for the synthesis of L1, L2 was obtained 0.48 g (41%) isolated yield. Mp: 215–217 °C. 1H NMR (CDCl3, 400 MHz, ppm): δ 7.89–7.83 (m, 4H), 7.48–7.33 (m, 8H), 7.20–7.15 (m, 3H), 6.89 (s, 2H), 6.78 (d, J = 8.4 Hz, 1H), 6.61 (d, J = 7.2 Hz, 1H), 5.07 (s, 1H), 2.56 (t, J = 7.2 Hz, 2H), 2.43 (t, J = 7.6 Hz, 2H), 2.05 (s, 6H). 1.10 (t, J = 7.6 Hz, 6H). 13C NMR (CDCl3, 100 MHz, ppm): δ 161.2, 160.8, 148.5, 148.4, 141.0, 140.6, 136.6, 131.0, 130.7, 129.6, 129.5, 128.9, 128.8, 128.2, 128.1, 127.3, 127.2, 126.4, 125.4, 125.1, 124.0, 122.9, 122.5, 119.9, 54.2, 24.7, 17.8, 13.8. FT-IR (cm−1): 2964 (m), 2928 (w), 2870 (w), 2360 (m), 2334 (w), 1671 (νCN, m), 1646 (νCN, m), 1593 (m), 1472 (w), 1439 (s), 1371 (m), 1257 (w), 1230 (m), 1149 (w), 1084 (m), 1033 (m), 922 (s), 881 (w), 830 (m), 776 (s), 733 (s), 667 (m). Anal. Calcd for C43H36N2 (580.78): C, 88.93; H, 6.25; N, 4.82. Found: C, 88.77; H, 6.28; N, 4.91.

4.2.4 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-diisopropylphenylimino)acenaphthylene (L3)

Using the similar procedure as for the synthesis of L1, L3 was obtained 0.62 g (51%) isolated yield. Mp: 206–208 °C. 1H NMR (CDCl3, 400 MHz, ppm): δ 7.90–7.84 (m, 5H), 7.49–7.41 (m, 5H), 7.36 (t, J = 7.6 Hz, 5H), 6.89 (s, 2H), 6.62 (qt, J = 6.8 Hz, 2H), 5.07 (s, 1H), 3.01 (m, 2H), 2.05 (s, 6H), 1.22 (d, J = 6.8 Hz, 6H), 0.96 (d, J = 8.0 Hz, 6H). 13C NMR (CDCl3, 100 MHz, ppm): δ 161.1, 160.9, 148.4, 147.4, 141.0, 140.7, 136.6, 135.4, 131.1, 129.5, 128.9, 128.8, 128.2, 127.9, 127.3, 127.2, 125.4, 125.1, 124.3, 123.5, 123.3, 122.5, 119.9, 54.2, 28.6, 23.3, 17.7. FT-IR (cm−1): 2965 (m), 2361 (s), 2355 (w), 1664 (νCN, m), 1636 (νCN, m), 1588 (m), 1471 (w), 1439 (s), 1379 (m), 1272 (w), 1225 (w), 1185 (w), 1145 (m), 1083 (w), 1039 (w), 923 (s), 896 (m), 833 (s), 781 (s), 737 (s), 665 (m). Anal. Calcd for C45H40N2 (608.83): C, 88.78; H, 6.62; N, 4.60. Found: C, 88.52; H, 6.80; N, 4.47.

4.2.5 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,4,6-trimethylphenylimino)acenaphthylene (L4)

Using the similar procedure as for the synthesis of L1, L4 was obtained 0.52 g (57%) isolated yield. Mp: 222–224 °C. 1H NMR (CDCl3, 400 MHz, ppm): δ 7.89–7.84 (m, 4H), 7.49–7.35 (m, 8H), 6.97 (s, 2H), 6.88 (s, 2H), 6.76 (d, J = 8.2 Hz, 1H), 6.61 (d, J = 4.0 Hz, 1H), 5.07 (s, 1H,), 2.37 (s, 3H), 2.08 (s, 6H), 2.04 (s, 6H). 13C NMR (CDCl3,100 MHz, ppm): δ 161.2, 161.0, 148.4, 148.3, 146.8, 141.0, 140.6, 136.7, 136.6, 132.9, 131.0, 129.7, 129.6, 129.0, 128.9, 128.8, 128.2, 127.3, 127.2, 125.4, 125.2, 124.6, 122.5, 122.4, 119.9, 54.2, 21.0, 17.8. FT-IR (cm−1): 2910 (w), 2360 (w), 1667 (νCN, m), 1642 (νCN, m), 1593 (m), 1472 (s), 1442 (s), 1377 (w), 1268 (m), 1232 (m), 1207 (w), 1181 (w), 1146 (m), 1091 (m), 1028 (m), 922 (m), 892 (m), 865 (w), 830 (m), 780 (s), 734 (s),700 (w), 668 (m). Anal. Calcd for C42H34N2 (566.75): C, 89.01; H, 6.05; N, 4.94. Found: C, 89.12; H, 6.80; N, 4.47.

4.2.6 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-diethyl-4-methylphenylimino)acenaphthylene (L5)

Using the similar procedure as for the synthesis of L1, L5 was obtained 0.58 g (52%) isolated yield. Mp: 227–229 °C. 1H NMR (CDCl3, 400 MHz, ppm): δ 7.89–7.84 (m, 4H), 7.49–7.33 (m, 8H), 7.00 (s, 2H), 6.89 (s, 2H), 6.73 (d, J = 6.0 Hz, 1H), 6.60 (d, J = 6.8 Hz, 1H), 5.07 (s, 1H), 2.57–2.48 (m, 3H), 2.41–2.36 (m, 4H), 2.04 (s, 6H), 1.09 (t, J = 7.6 Hz, 6H). 13C NMR (CDCl3, 100 MHz, ppm): δ 161.2, 160.9, 148.4, 146.0, 141.0, 140.6, 136.6, 133.1, 131.0, 130.6, 129.7, 129.6, 128.9, 128.7, 128.3, 128.2, 128.1, 127.3, 127.2, 126.8, 125.4, 125.2, 123.0, 122.4, 119.9, 119.5, 54.2, 24.7, 21.2, 17.8, 13.9. FT-IR (cm−1): 2963 (w), 2167 (w), 1975 (w), 1667 (νCN, m), 1644 (νCN, m), 1594 (m), 1441 (s), 1372 (w), 1274 (w), 1230 (m), 1149 (m), 1089 (w), 1028 (m), 921 (m), 891 (w), 858 (m), 831 (s),780 (s), 732 (s), 665 (m). Anal. Calcd for C44H38N2 (594.80): C, 88.85; H, 6.44; N, 4.71. Found: C, 88.60, H, 6.55, N, 4.61.

4.3 Synthesis of nickel complexes D1–D5

4.3.1 1-(4-(Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-dimethylphenylimino)acenaphthylnickel bromide (D1)

To a mixture of L1 (0.110 g, 0.20 mmol) and (DME)NiBr2 (0.063 g, 0.20 mmol) was added CH2Cl2 (10 mL) in a 50 mL Schlenk flask. The reaction mixture was stirred for 24 h at room temperature, and excess diethyl ether was added to precipitate the complex. The complex was collected by filtration, washed with diethyl ether (3 × 5 mL), and then dried under vacuum to obtain a deep red powder of (D1) (0.138 g) in 90% yield. FT-IR (KBr, cm−1): 2972 (w), 2166 (w), 1652 (νCN, w), 1626 (νCN, m), 1583 (m), 1470 (w), 1441 (m), 1380 (w), 1293 (m), 1243 (w), 1193 (w), 1109 (w), 1083 (w), 1045 (m), 955 (w), 894 (w), 829 (s), 771 (s), 738 (s), 667 (w). Anal. Calcd for C41H32N2NiBr2 (771.21): C, 63.85; H, 4.18; N, 3.63. Found: C, 63.78; H, 4.13; N, 3.79.

4.3.2 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-diethylphenylimino)acenaphthylnickel bromide (D2)

Using the similar procedure for D1, D2 was obtained as a red powder. (0.145 g, 88% yield). FT-IR (KBr, cm−1): 2930 (w), 2872 (w), 2285 (w), 2185 (w), 2162 (m), 2050 (w), 1980 (m), 1659 (w), 1651 (νCN, w), 1632 (νCN, m), 1583 (s), 1557 (w), 1477 (w), 1445 (s), 1422 (w), 1373 (w), 1300 (m), 1251 (w), 1226 (m), 1189 (m), 1154 (w), 1136 (w), 1032 (s), 828 (s), 794 (m), 774 (s), 742 (s), 688 (w), 671 (m). Anal. Calcd for C43H36N2NiBr2 (799.28): C, 64.62; H, 4.54; N, 3.50. Found: C, 64.54; H, 4.45; N, 3.42.

4.3.3 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-diisopropylphenylimino)acenaphthylnickel bromide (D3)

Using the similar procedure for D1, D3 was obtained as a brown-red powder. (0.152 g, 93% yield). FT-IR (KBr, cm−1): 2965 (m), 2920 (w), 1651 (νCN, w), 1620 (νCN, m), 1583 (m), 1438 (s), 1382 (w), 1358 (w), 1287 (m), 1254 (w), 1182 (m), 1091 (w), 1047 (w), 828 (s), 805 (w), 777 (s), 740 (s), 672 (m). Anal. Calcd for C45H40N2NiBr2 (827.33): C, 65.33; H, 4.87; N, 3.39. Found: C, 65.49; H, 4.86; N, 3.26.

4.3.4 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,4,6-trimethylphenylimino)acenaphthylnickel bromide (D4)

Similarly, D4 was obtained as a brown-red powder. (0.138 g, 91% yield). FT-IR (KBr, cm −1): 2979 (w), 2854 (w), 2168 (w), 1984 (w), 1635 (νCN, m), 1609 (νCN, w), 1589 (m), 1480 (s), 1444 (m), 1384 (w), 1303 (m), 1247 (w), 1200 (w), 1158 (m), 1110 (s), 1073 (w), 1024 (w), 879 (w), 843 (m), 802 (m), 765 (w), 742 (s), 679 (m), 656 (w). Anal. Calcd for C42H34N2NiBr2 (785.25): C, 64.24; H, 4.36; N, 3.57. Found: C, 64.12; H, 4.35; N, 3.83.

4.3.5 1-(4-Fluorenyl-2,6-dimethylphenylimino)-2-(2,6-diethyl-4-methylphenylimino)acenaphthylnickel bromide (D5)

Similarly, D5 was obtained as a red powder. (0.146 g, 89% yield). FT-IR (KBr, cm−1): 2965 (m), 2903 (w), 2870 (w), 1646 (νCN, w), 1619 (νCN, m), 1584 (s), 1444 (s), 1380 (m), 1288 (m), 1231 (w), 1203 (w), 1149 (m), 1071 (s), 1033 (w), 859 (m), 828 (s), 772 (s), 733 (s), 669 (m). Anal. Calcd for C44H38N2NiBr2 (813.30): C, 64.98; H, 4.71; N, 3.44. Found: C, 64.82, H, 4.51; N, 3.65.

4.4 General procedure for ethylene polymerization

Ethylene polymerization at ambient pressure. The pre-catalyst was dissolved in dry toluene using standard Schlenk techniques, and the reaction solution was stirred with a magnetic stir bar under ambient ethylene atmosphere (1 atm) with a steam bath for controlling the desired temperature. Finally, the required amount of co-catalyst (MAO or EASC) was added by a syringe into the solution. After the reaction was carried out for the required period and then the reaction solution was collected and quenched with 10% hydrochloric acid in aqueous ethanol. The precipitated polymer was collected by filtration, washed with ethanol and water, and dried in a vacuum at 60 °C until constant weight.

Ethylene polymerization at elevated pressure (10 atm). A 300-mL stainless steel autoclave, equipped with a mechanical stirrer and a temperature controller, was employed for the reaction. First, 50 mL of toluene (freshly distilled) was injected into the autoclave filled with ethylene. When the required temperature was reached, another 30 mL of toluene in which was dissolved the complex (2.0 μmol of nickel), the required amount of co-catalysts (MAO, MMAO, EASC, Et2AlCl and Me2AlCl), and the residual toluene (20 mL) were added by syringe successively. The reaction mixture was stirred intensely for the desired time under a corresponding pressure of ethylene through the entire experiment. The reaction was terminated and the mixture was analyzed using the same procedure as above for ethylene polymerization.

4.5 X-ray structure determination

Crystals of complex D5 were obtained by layering diethyl ether onto its chloroform solution. A single-crystal X-ray diffraction study for D5 was conducted on a Rigaku sealed tube CCD (Saturn 724+) diffractometer with graphite-monochromated Mo Kα radiation (λ = 0.710 73 Å) at 173(2) K, and cell parameters were obtained by global refinement of the positions of all collected reflections. Intensities were corrected for Lorentz and polarization effects and empirical absorption. The structure was solved by direct methods and refined by full-matrix least-squares on F2. All nonhydrogen atoms were refined anisotropically, and all hydrogen atoms were placed in calculated positions. Structure solution and refinement were performed by using the SHELXL-97 package [13]. Crystal data and processing parameters for D5 are summarized in Table 5.

Crystal data and structure refinement for C5·H2O.

| Identification code | [C5·H2O]·Et2O |

| Empirical formula | C48H50Br2N2NiO2 |

| Formula weight | 905.43 |

| T (K) | 173 (2) |

| Wavelength/(Å) | 0.71073 |

| Crystal system | Triclinic |

| Space group | P |

| a/(Å) | 10.025 (2) |

| b/(Å) | 15.265 (3) |

| c/(Å) | 15.621 (3) |

| alpha/(°) | 116.90 (3) |

| beta/(°) | 99.47 (3) |

| gamma/(°) | 92.74 (3) |

| Volume/(Å3) | 2082.4 (7) |

| Z | 2 |

| Dcalcd/(g cm−3) | 1.44 |

| μ (mm−1) | 2.426 |

| F(000) | 932 |

| Crystal size/mm | 0.35 × 0.31 × 0.19 |

| Theta range (°) | 1.49–27.54 |

| Limiting indices | −13 ≤ h ≤ 13 |

| −19 ≤ k ≤ 19 | |

| −20 ≤ l ≤ 20 | |

| No. of rflns collected | 28,210 |

| R(int) | 0.0637 |

| No. of parameters | 504 |

| Completeness to θ | 98.9% |

| Goodness of fit on F2 | 1.194 |

| Final R indices (all data) | R1 = 0.0660 |

| [I > 2∑(I)] | wR2 = 0.1730 |

| R indices (all data) | R1 = 0.0757 |

| wR2 = 0.1894 | |

| Largest diff. peak, hole/(e Å−3) | 1.275 and −0.978 |

Acknowledgement

This work is supported by National Natural Science Foundation of China (NSFC Nos. 21374123 and U1362204). VK and NMR thank the Chinese Academy of Sciences for the Visiting Scientist Fellowships. We are grateful to Dr. Gregory A. Solan for his English proofreading.

Appendix A Supplementary data

The following is the supplementary data related to this article:

CCDC 1425732 contains the supplementary crystallographic data for D5. These data can be obtained free of charge from The Cambridge Crystallographic Data Centre via www.ccdc.cam.ac.uk/data_request/cif.