1 Introduction

Spin-crossover (SCO) materials constitute nowadays a very promising research domain to go toward application in various fields incorporating molecular memories [1], pressure and temperature sensors [2,3], gas sensors [4,5], optoelectronic and actuators devices [6], nanothermometers [7], and other “general public” applications like displays and intelligent papers or paints [8,9]. Indeed, the specific behavior of these complexes reposes on their intrinsic and stable switch related to intramolecular electronic transitions. The SCO phenomenon is now well understood and it is accompanied by the modification of optical, magnetic, and volumetric properties of the materials. Different cornerstone discoveries have legitimated the growing interest for such family of materials, in particular, (1) the role of the intermolecular interaction within materials, which we call cooperativity, on the nature and the abruptness of the spin transition behavior [10]; (2) the possibility to have SCO with hysteresis loop in the case of exacerbated cooperativity affording the possibility to have a memory effect [1]; (3) the versatility of the stimuli that can be used to trigger the spin state, that is, temperature, light, magnetic, and electric field or the inclusion of a guest molecule [11–13]; (4) the possibility to have room temperature SCO transition (a paramount result was the discovery of a light-induced reversible switch in the hysteresis loop at room temperature) [14]; and more recently, (5) the maintaining of the bistable behavior in nanometric-sized particles or thin films [15–18]. In general, the macroscopic behavior of bulk SCO materials is strongly influenced by electron–lattice coupling effects. In particular, the modification of the volume and shape of the molecules accompanying the spin state change leads to considerable elastic interactions between them. These interactions give rise to various cooperative phenomena, such as first-order phase transitions or self-accelerating relaxations of metastable states. Research into SCO nanoparticles (NPs) is chiefly motivated by the long-standing question of the size effect on the first-order phase transition observed in many cooperative SCO systems. Particular attention is focused on the hysteresis property, which is expected to be strongly affected when decreasing the number of molecules constituting the particle. An important challenge in this context is to preserve the bistability and the cooperative spin transition properties during the downsizing of the compound at the nanoscale. So, in a first approximation, size reduction effects in SCO materials are expected to occur primarily due to the reduction in the number of interacting metallic centers and the associated decrease in the cooperativity. We shall see later that this picture is too simplistic and many other parameters and material properties have to be considered to interpret the experimental observations obtained with SCO nanomaterials. Because the investigation of the size effects on the bistability remains one of the main objectives in the field, there is a clear need for novel characterization tools and techniques with high spatial resolution as well as high sensitivity able to detect molecular spin state changes in very small amounts of matter, ideally in a single isolated nano-object. By the same token, these studies open up also new perspectives for the development of applications [19].

The first part of this review concerns the syntheses and characterizations of the physical properties of SCO NPs. Section 2 starts with the description of various techniques including homogeneous and heterogeneous media syntheses developed for the elaboration of such NPs and the associated methods used for their morphological characterization. Then, an exhaustive state of the art concerning the size, shape, and the SCO properties of molecular and polymeric complex particles is reported. A particular attention is paid on the effects of the size reduction on the SCO properties and to specific and recent remarkable advanced physical measurements realized on a batch of NPs or on an isolated object. Section 2.3 is dedicated to the influence of the matrix and the surface on the SCO behavior.

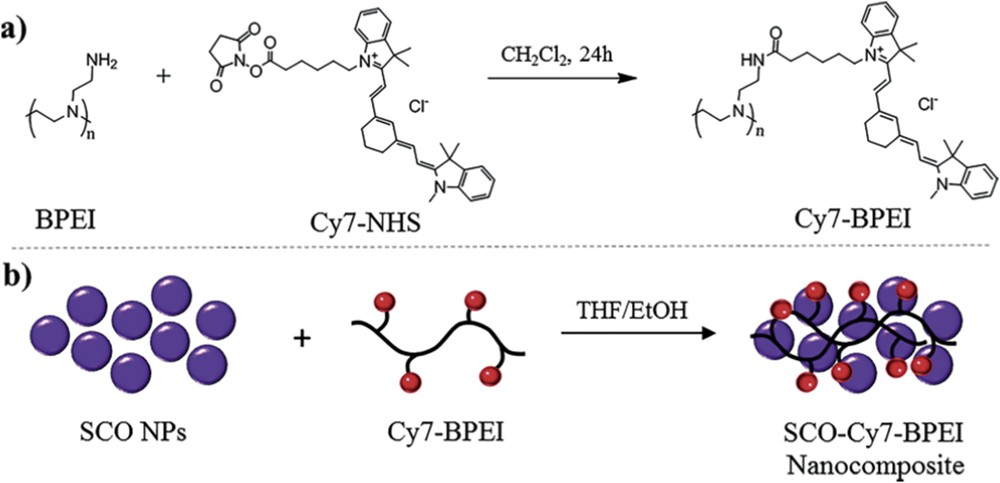

The second part of this review presents the state of the art of various nanocomposite or nanohybrid materials based on SCO compounds. Indeed, SCO materials have been associated with magnetic entities, noble metals, different fluorescent dyes, and different active polymers with several objectives in mind. First, to be able to probe the SCO properties of a reduced quantity of matter and ideally a single particle, and on the other hand, to try to go toward specific applications based on synergistic effects between the two components.

2 SCO nanoparticles

2.1 Methods for the elaboration and characterization of SCO NPs

This section intends to review the main bottom-up synthetic processes and characterization techniques that have been used on various SCO nanomaterials. These synthetic methods have been extensively applied to oxide/sulfide/metallic NPs. The aim of this introductive part is to stress the specificities, advantages, and drawbacks of the different methods for downscaling SCO compounds. More experimental details on each compound will be provided in Section 2.2. Three main synthetic routes may be distinguished: hard template, soft template, and template-free synthesis. Concerning the characterization techniques of such nanomaterials, rather than fully describing each technique we will stress the importance of the complementary information that may be extracted and a few basic points for any newcomer in the field. These basic characterizations are compulsory to establish reliable studies on SCO nanomaterials and avoid inconsistent comparisons.

2.1.1 Hard template synthesis

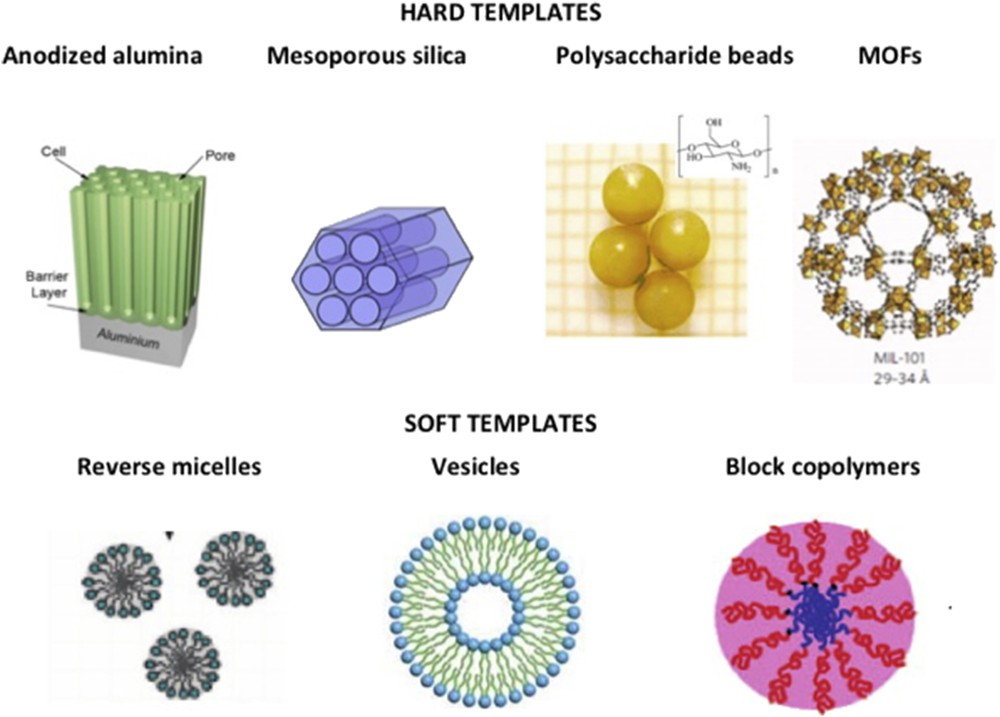

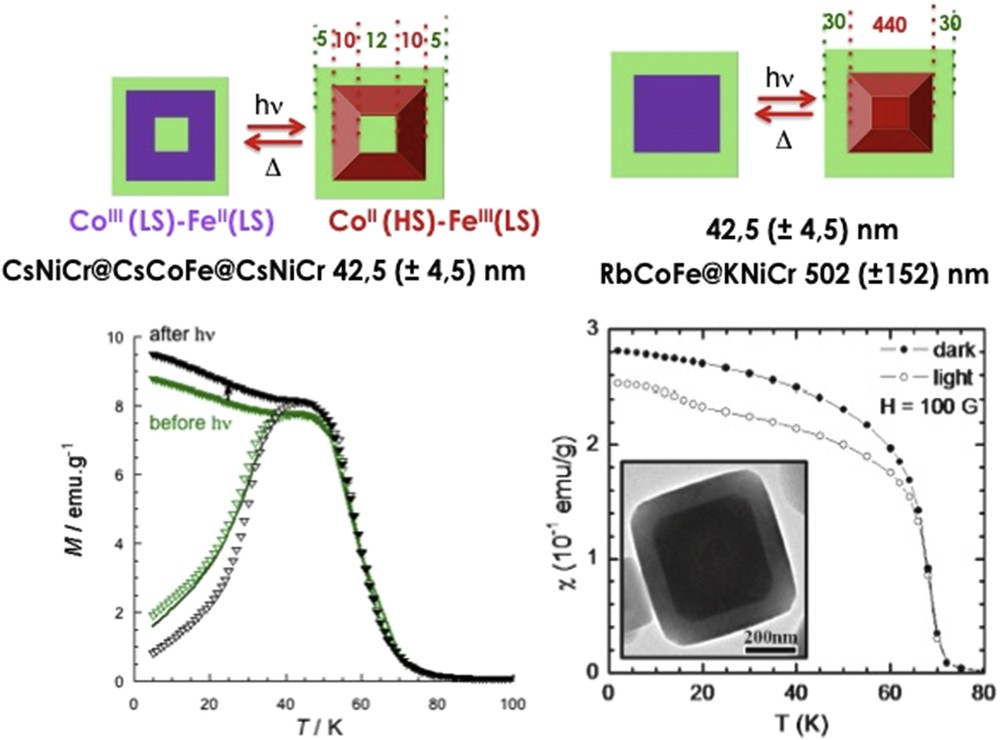

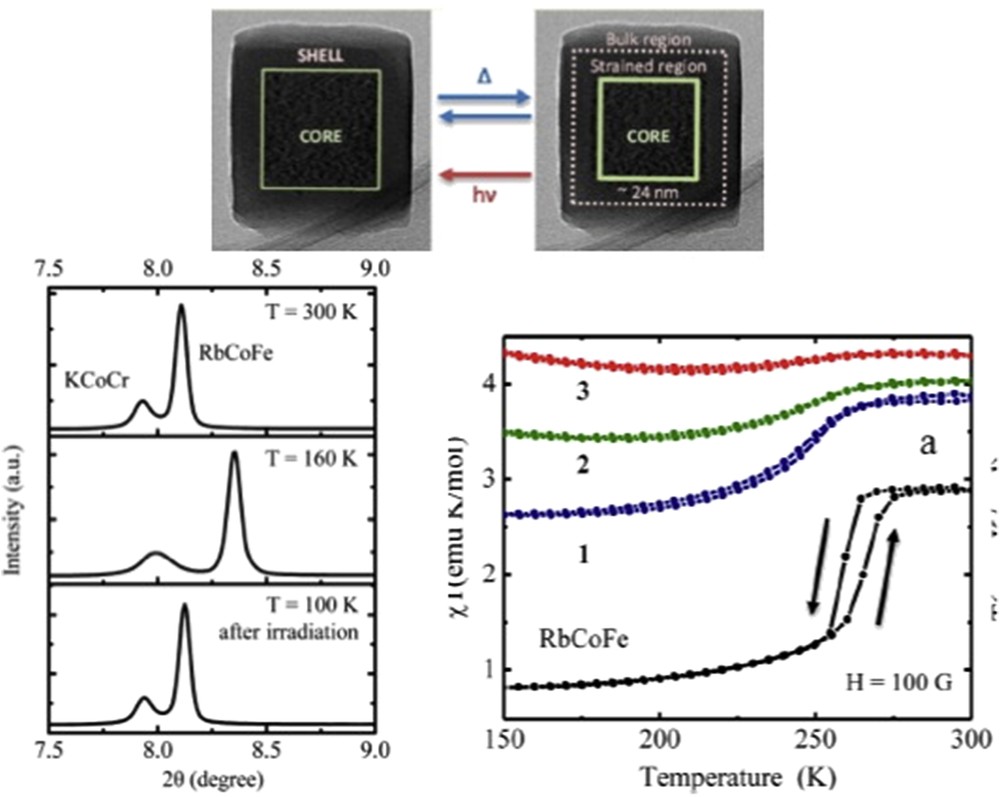

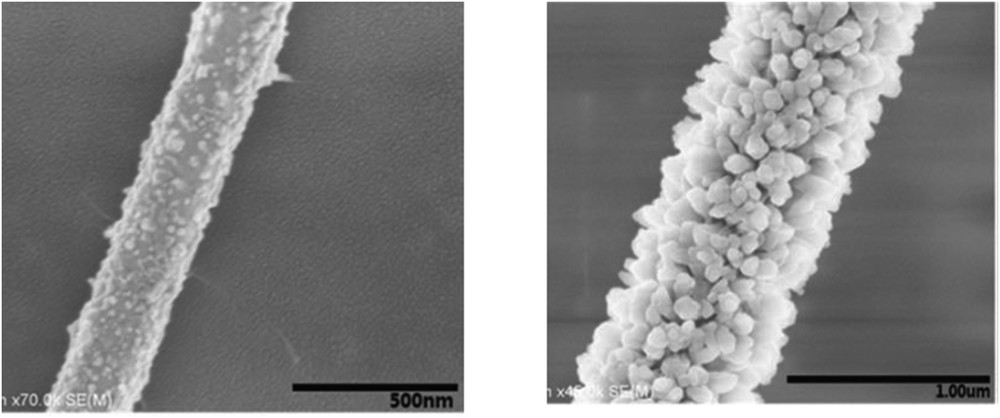

Synthesis of coordination NPs in hard templates such as silica, anodized alumina, polysaccharide beads, and a few other templates have been reported along the last decade for several coordination polymers (CPs) starting with the most studied Prussian blue analogues (PBA). The main advantage over other synthetic strategies relies on the fact that the nano-objects may be directly shaped by the template porosity with a controlled and predictable size and shape tuned by that of the pores (Fig. 1, top). One main difficulty of the hard template approach is to confine growth within the mesoporosity only and avoid any precipitation on the external surface, and the use of functionalized internal pores (by ligands or preincorporated metal centers) is the most recommended strategy. The precipitation of SCO inside the pores can also be done by adjusting the water volume around 80% of the porous monolith volume and immersing it in an apolar immiscible solvent such as hexane [20]. Oxide-based hard templates are convenient to control growth of PBA coordination networks as recently reviewed [21]. Among PBAs, the AxCo[Fe(CN)6]y family (A = Cs+, Rb+, Na+, etc.) is highly interesting as it exhibits thermo- and photoswitchable behavior that involves a charge transfer–induced spin transition (CTIST) depending on the nature and amount of the inserted alkali cation A+ [22–24]. Although no study was reported on PBA NPs that usually display thermal CTIST (with A = Rb+, Na+) most likely because of the disappearance of the transition with size reduction and/or the matrix effect, photoswitchable RbxCo[Fe(CN)6]y PBA NPs embedded in templates have been reported by several methods. To a lesser extent, SCO NPs were also produced in hard templates. A few examples are provided to illustrate each method.

Schematic representation of some templates (hard and soft) that may be applied to the controlled growth of SCO NPs.

A first strategy, even if it may not be fully considered as “hard template” in some cases, is based on sol–gel synthesis to confine the nucleation and growth processes in a silica xerogel obtained by hydrolysis of alkoxysilanes (as TEOS or TMOS) in basic or acidic conditions. The first example reported 8–10 nm KCoFe NPs entrapped in a xerogel that did exhibit photomagnetic behavior but where the formation of the gel and PBA were not decoupled [25]. Another process was developed by Fornasieri et al. [26], which consists in the addition of a cobalt(II) basic solution to the silica sol that leads to the formation of unreactive tetrahedral species, and subsequent addition of a ferricyanide solution that enables the insertion of both precursors without formation of the PBA. A simple acidification step restores the octahedral CoII species that immediately react to form the RbxCo[Fe(CN)6]y particle. Concerning SCO compounds, NPs around 2.5–5 nm were obtained for the one-dimensional (1D) [Fe(Htrz)2(trz)](BF4) CP within a silica xerogel by adding an aqueous solution of the preformed complex into a methanolic solution of alkoxysilane at pH = 5 followed by aging and drying in mild conditions in different containers to control their shaping as film, disk, or monolith (test tube or Petri dish) [27]. Fairly good crystallinity was achieved but partial oxidation of FeII to FeIII was evidenced by Mössbauer spectroscopy. When producing silica nanocomposite films, a crucial parameter is the increase in the aging time that tunes the viscosity of the gel before the spin coating of the film. Size is critically affected by this parameter, as illustrated for the mononuclear complex [Fe((mepy)3tren)](PF6)2 where the average size was tuned between 47 and 730 nm when aging between 2 weeks and 1 h, respectively [28].

Besides, silica mesoporous matrices have calibrated and organized porosity with the widest range of structuration and shaping possibilities (powder, film or monolith) because of the well-developed surfactant-assisted sol–gel processes. The optical and mechanical performances as well as good thermal stability are highly appealing, especially when photoswitchable particles are targeted. This has allowed us to control various PBA NPs, among which NPs of 5 nm of Rb0.5Co[Fe(CN)6]0.82 (containing CoIIIFeII photoswitchable pairs) were successfully synthesized within silica monoliths by a two-step method: a first step based on CoII octahedral complexes solubilized in the copolymer and subsequent calcination that induces grafting of tetrahedral CoII species with a low degree of condensation onto the silica pore walls, and a second step by impregnation with an acidic solution of ferricyanide that restores the octahedral CoII species followed by immediate precipitation of PBA NPs [29].

A preformed silica monolith was also used to confine SCO polymers such as [Fe(Htrz)2(trz)](BF4) [30]. This two-step approach led to 3 nm [Fe(Htrz)2(trz)](BF4) spherical particles. Furthermore, the use of hexagonal MCM-1 (Mobil Crystalline Materials) with pores from 2 to 2.7 nm in diameter was reported to grow the 1D CPs [Fe(Htrz)2(trz)](BF4) and [Fe(Htrz)3](BF4)2 in the cylindrical pores, leading to crystalline spherical NPs around 2 nm in both cases without any oxidation. In both cases, the compound that deposited on the external surface of the powders was washed out easily. Other nanoporous templates such as metal–organic frameworks may also be envisaged to produce particles less than 2 nm in size. One example of [Fe(HB(pz)3)2] SCO complex in several types of MIL-101 was obtained directly during synthesis of the metal–organic framework itself and may be extended to produce other types of ultrasmall particles [31]. In the case of 3D Hofmann clathrates, confinement in silica templates was not reported apart from one attempt with a CoII compound (that does not exhibit SCO [32]), even if the grafting of a ligand on the internal walls of the pores using pyridine or click chemistry may be applied to coordinate the FeII species. This may be related to the difficulty to avoid defects in pyrazine during the washing steps. Still hard templates of polysaccharides (chitosan and alginate beads) were successfully used on the {Fe(pyrazine)[M(CN)4]} (M = Pt, Pd, Ni) 3D compounds and PBAs. Anchoring in the polysaccharide beads is achieved, thanks to the coordination of NH3 or COOH groups to FeII in chitosan and alginate, respectively. Successive impregnation was performed with the three precursors (iron salt, pyrazine, and tetracyanometallate salt) and was optimized to ensure precipitation occurred within the porosity only. This was done by extensive washing with methanol after each step. This synthetic method cannot be simply transposed from one compound to another, as the ratio between the two metals M/Fe strongly depends on the MCNFe bond strength, and incomplete coordination occurred when M = Pt, Pd, whereas M = Ni leads to the expected Ni/Fe = 1. This has tremendous consequences on the SCO behavior (see subsequently). The number of defects after the rinsing steps may be also complicated by the fact that while the 2D cyanide-bridged sheets are easily formed by reacting FeII salts with tetracyanometallates, the complete interconnection of these planes by pyrazine to form the defectless 3D structure requires the use of solvent mixtures, low temperature, or high concentrations in precursors. Such polysaccharide templates have the advantage to induce confinement below 4 nm and the particles may be postdispersible in solvents, whereas oxide-based templates require the use of harsh conditions (strong base or HF) to extract the NPs that may damage the material crystallinity and composition. With all of these hard template methods, spherical NPs were identified, despite the cylindrical shape of most pores in silica that may favor rod-shaped particles by coalescence of particles in the channels. Larger cylindrical pores of porous alumina membranes are more favorable to tune the shape of SCO particles. These membranes are obtained by oxidation of aluminum and periodic dissolution of alumina under applying an electric field leading to hexagonal packing of pores perpendicular to the surface with an average diameter typically greater than 50–300 nm (and many micrometers in length). Anodized alumina was used, for instance, to prepare several types of PBA nanowires or nanotubes (by electrodeposition) [33,34] and nanowires of the molecular SCO complex [Fe(sal2-trien)] (80–100 nm width, micrometer length) [35]. Cationic exchange resin beads were also used where successive impregnation with the precursors to produce alignment of nanorods of Fe triazole polymers at the periphery of the beads (see subsequently); in this case, the template promotes a release of Fe and a controlled nucleation at the surface and the shape of the particles is related to the 1D structure of the compound itself [36].

Most of these hard template methods are in general not straightforward, lead to low yields of highly diluted paramagnetic nanocomposites difficult to measure. Also of utmost importance, the rigid matrix plays a noninnocent and complex role on the cooperativity, transition temperature, and completeness of the SCO phenomenon, as detailed in Section 2.3. It should be reminded that this strategy always couples size effects to matrix/interfacial effects that may either be beneficial or detrimental to the SCO cooperative character.

2.1.2 Soft template/polymer-assisted synthesis

Multiple routes are available to control nucleation and growth by using self-assembled nanostructures based on surfactants or polymers where nanometric pools may confine the growth (Fig. 1, bottom). A water-in-oil microemulsion is an optically transparent and thermodynamically stable dispersion of water in an apolar solvent stabilized by an interfacial film of a surfactant, sometimes in combination with a cosurfactant. It has been efficiently used to downscale many inorganic materials as pioneered by Pileni [37]. Reverse water-in-oil micelles are nanometric water pools stabilized in the apolar phase by surfactants (organic compounds having a hydrophilic “head” and a hydrophobic “tail”) with low packing parameters g = V/Al around 1/3, where V is the molar volume of the surfactant, A is the area per head group, and l is the contour length of the alkyl chain. Charged surfactants may be used as the most employed anionic bis(2-ethylhexyl) sulfosuccinate (AOT) or cationic cetyltrimethylammonium, but also neutral as Brij, Igepal, Laurepal, Tergitol that all include water-soluble oxyethylene oligomers.

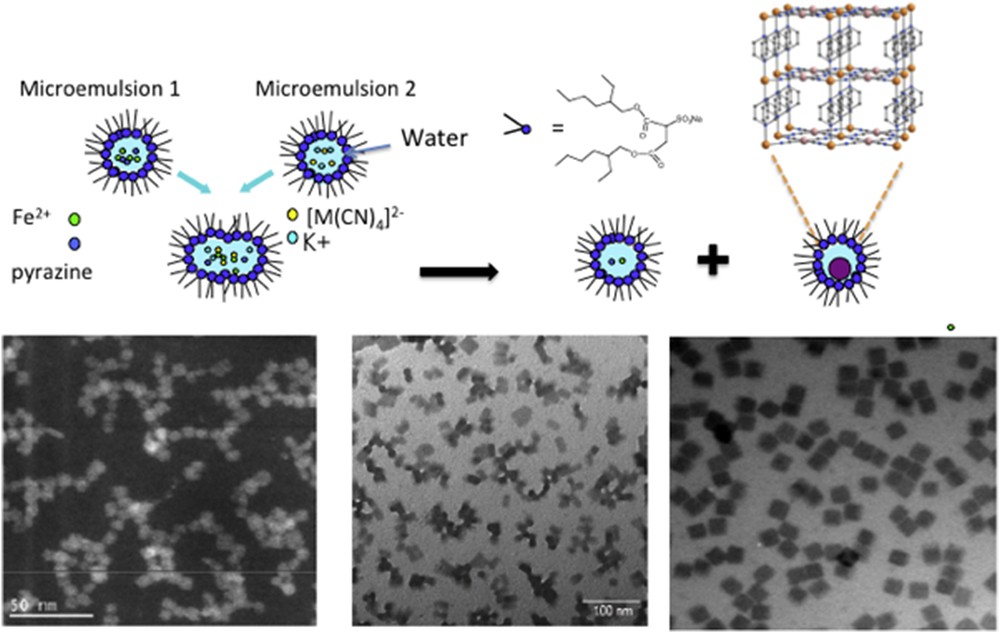

This method was first applied to PBA coordination networks [38] and is perfectly adapted to SCO compounds that are insoluble in water and obtained from water-soluble precursors. The two water-soluble precursors are separately dissolved in the desired volume of water and the surfactant dissolved in the apolar solvent (alkane) is added under vigorous stirring (that may be accelerated by sonication) to obtain the two separate translucent microemulsions. Brownian motion promotes the fusion of micelles that exchange their content leading to the formation of the water-insoluble compound. This process was successfully applied to SCO polymers such as iron triazole–based 1D polymers and {Fe(pyrazine)[M(CN)4]} 3D Hofmann clathrates (M = Pt, Pd, Ni) (Fig. 2). Furthermore, it has been applied to the mononuclear complex [Fe(phen)2(NCS)2] by Valverde-Muñoz et al. [39] to produce rhombohedral particles around 150–200 nm large. The iron and thiocyanate precursors were contained in one microemulsion and a methanolic solution of phenanthroline was used to stabilize the second microemulsion. A detailed description for each sample will be given in section 2.2, but some general features may be underlined. The first point is obviously to work with a water/oil/surfactant ratio where reverse micelles are stable in the corresponding ternary diagram that depends on the oil/surfactant mixture, and this is favored for surfactants that have large hydrophobic tails (g = 1/3). Concentration in precursors within the water pools is one parameter that affects the size as a nucleation-controlled process is often favored. Smaller particles are generally produced when higher concentrations of precursors are used. An important point is to maintain the stability of the microemulsion over time and avoid any uncontrolled flocculation process, so that concentration may not be increased above a certain threshold that is compounddependent. Particle size strongly depends on the solubility of the compound and interaction with the surfactant, so that physicochemical parameters can hardly be extrapolated from one compound to another. Furthermore, the water/surfactant ratio ω may be varied between 5 and 50 (depending on the ternary system) and it tunes the water nanopool size. The size of the reverse micelles linearly depends on ω but is restricted to a small size range depending on the system (much less than 50 nm). For instance in the case of AOT/water/isooctane ternary system (with [AOT] = 0.1 M), a change in ω from 5 to 35 tunes the water pool diameter from 3 to 14 nm. However, apart from low water content (ω = 5) where the micelle size controls the particle size through interfacial energy of the boundary surfactant, size and shape may be very different from the initial water pool size and unpredictable, due to controlled aggregation and reorganization of the surfactant at the particle surface. Nanorods of [Fe(Htrz)2(trz)](BF4), around 100 × 10 × 10 nm3 [40], may be produced in AOT-stabilized water-in-oil reverse micelles beyond the size of the initial water pools meaning that the growth of the crystal facets is dominant and the surfactant reorganizes at the nanocrystal surface. However, this is a typical case where the growth of the nanocrystals is not totally controlled by the micelles and the flocculation of the microemulsion occurs after 30 min. A major point is to preserve individualized particles after flocculation of the microemulsion, maintaining their processability and avoiding irreversible coalescence. Importantly, the excess of surfactant strongly modifies the SCO behavior (either increasing or suppressing the cooperativity depending on the compound, see Section 2.3). In many reports, flocculation is done by adding a solvent (acetone, ethanol, etc.) and several washing steps of AOT with acetone are performed, but it is hard to insure that no coalescence has occurred (that may change the properties) and only dynamic light scattering/transmission electron microscopy (DLS/TEM) on dispersed sample after the washing process provides a clear proof, which is scarcely mentioned in the literature. With iron triazole–based CPs, the compound contains cationic chains and anions located in between. Anionic surfactants have, therefore, a strong affinity with the particles because of the electrostatic interaction with the cationic CPs, so that the extensive washings of AOT are possible keeping a monolayer of AOT only at the surface. This is not the case of neutral Hofmann clathrates. In most cases, a small amount of AOT remains in the sample (even if it may be totally suppressed), but this quantity has to be severely controlled to compare SCO properties in a reliable way between different samples. When extensively washed, partial coalescence of particles during the washing process may occur and is hard to characterize even with X-ray diffraction (XRD). A way to avoid any problem is to protect the particle during the flocculation step by a molecule/coating that strongly binds to the surface more than the surfactant itself. A convenient recovery consisted in using pyridine-based ligands that coordinate at the FeII sites located on the surface [41]. To avoid decoordination of monodentate ligands during the multiple washing steps while maintaining subsequent dispersibility in organic solvents, one successful strategy relies on using a strongly chelating ligand with eight pyridine groups (linked covalently to a calix-[8]arene ring) without affecting the composition and shape. The most convincing way to show that the integrity of the particle has been maintained is to disperse the particles after the washing steps and characterize them by DLS, TEM, and energy-dispersive X-ray (EDX) spectroscopy [41].

Example of water-in-oil microemulsion method to tune size of Fe(pyrazine)[Pt(CN)4] depending on physicochemical parameters (decrease of the precursors concentrations from left to right).

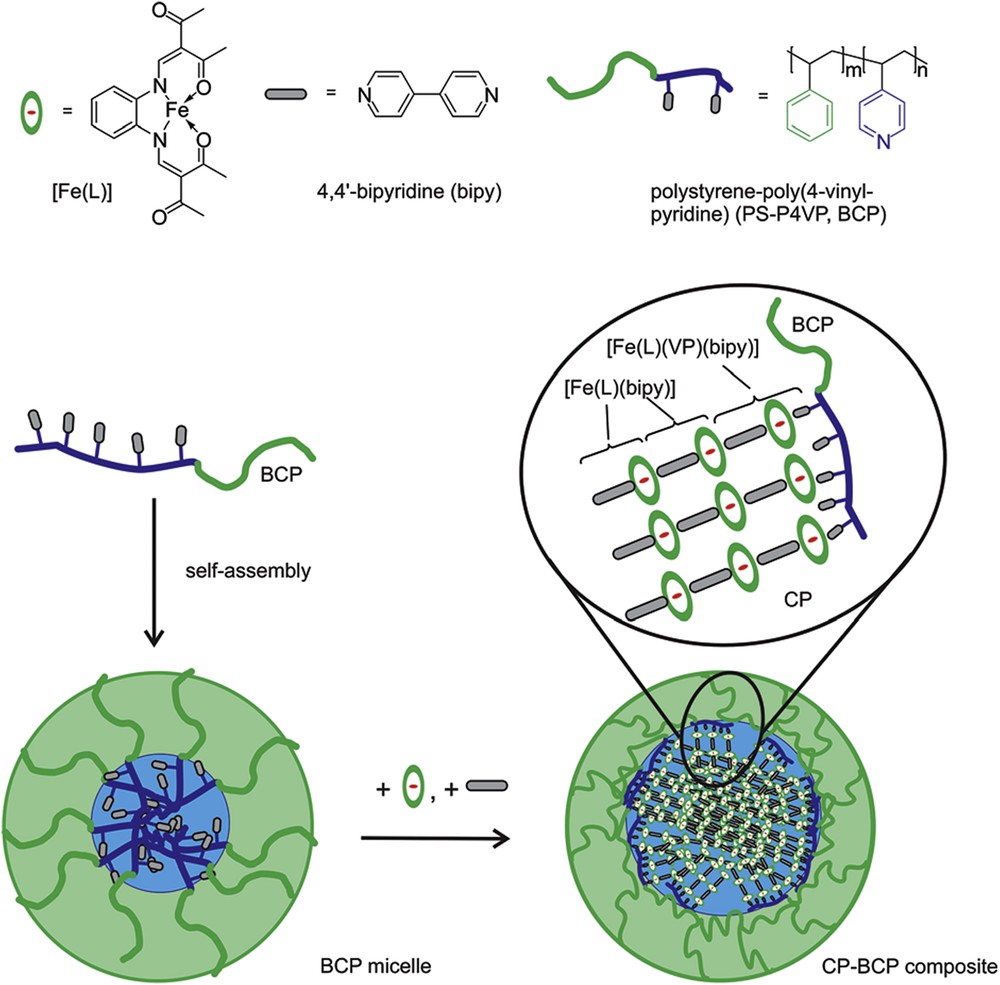

Apart from surfactant, block copolymers (BCPs) form micellar structures because of the strong difference in solubility between one block and the other in a chosen solvent [42]. If this solvent is water as for copolymers having a hydrophilic block (such as poly(ethylene glycol), polysulfonate, polyvinylpyridine, polypyrrolidone, etc.) the core will be formed by the hydrophobic part and will serve to encapsulate apolar compounds, whereas the use of a less polar solvent may lead to a more polar core. The advantages of this method are as follows: (1) it may be applied in solvents others than water (thus applicable to neutral reactants and products); (2) the size of the particles may be larger than those obtained with other strategies; (3) the use of coordinating functions in the core may lead to controlled location of the reactants in the cores; and (4) the obtained colloids may be easily processed by slow evaporation of the solvent to lead to ordered structures and films. Only one example has been reported to date using polystyrene-poly-4-vinylpyridine in THF to form 50 nm particles of a 1D CP [Fe(L)(bipy)]n (with L = 1,2-phenylenebis(iminomethylidyne)bis(2,4-pentanedionato)(2-) and bipy = 4,4′-bipyridine) starting from the neutral [Fe(L)(MeOH)2] complex and bipyridine. Repeated addition of the precursors at high temperature led to NPs with an enhanced crystallinity that were isolated by cold distillation of the solvent [43] (see Fig. 3).

Schematic representation of a self-assembled BCP micelle for use as a nanoreactor. Successive addition of the complex [Fe(L)] and the bridging ligand bipy to the BCP micelle will lead to a growth of the CP in the core of the micelle. Adapted from Ref. [43].

Besides the use of self-assembling BCPs, polymer-assisted coprecipitation is also commonly used. The polymer is chosen to interact with the particles through coordination bonds, hydrogen bonds, or electrostatic interactions that help to control nucleation and efficiently limit the aggregation of particles by inducing steric or electrosteric stabilization. This strategy is different from studies on nanocomposites where the compound is prepared and simply suspended in a matrix. The polymer/precursor ratio may control the size of the NPs, but often mainly avoids secondary aggregation and reorganization steps. Polyvinylpyrrolidone (PVP) has been efficiently used to stabilize photomagnetic NPs of octacyanometallate-based networks (spherical or nanorods) and CoFe PBA between 3 and 50 nm (spherical or cubic) but more scarcely used for SCO compounds to control the growth. Again one should keep in mind that the influence of the polymer embedding the particles may strongly affect the SCO behavior (see Section 2.3).

In sub-100 nm Hofmann clathrate NPs surrounded by PVP, suppression of the cooperativity was observed by Volatron [44] (later on attributed to a strong matrix effect). Platelets of a 2D Hofmann clathrate were reported by Martinez et al. [45] stabilized in PVP with similar effects. For iron triazole 1D CPs, several polymers (PVA, PEG, Triton, etc.) [46] have been used leading to rather large particles but it remains difficult to produce nanostructures less than 100 nm using this approach (see section 2.2), probably due to rather weak interactions with the particles.

2.1.3 Surfactant-free synthesis

Besides these template-based methods that are efficient routes to control particle size less than 10 nm, other homogeneous synthetic strategies may be applied that do not require any stabilizer/template. The main requirement is to produce an efficient nucleation step avoiding overlap of nucleation and growth events. This may be done as proposed by Lamer and Dinegar [47] on colloidal sulfur by inducing high supersaturation in a reactant either by producing the reactive moieties progressively from a precursor (as hydrolysis in sol–gel synthesis) or by changing the solubility by adding a miscible nonsolvent and/or changing the temperature. Monodisperse particles may be produced, starting from precursors that are soluble in a solvent (that may act as a ligand toward the transition metal such as water) and adding a miscible antisolvent to provoke the nucleation event with primary particles that may often subsequently lead to secondary particles by fusion [48].

For instance, valence tautomerism particles were prepared by connecting {CoIII(3,5-dbsq)(3,5-dbcat)} units through the 1,4-bis(imidazol-1-ylmethyl)benzene (bix) ligand, achieving a so-called “infinite CP”. For this compound, spherical amorphous particles were obtained with a tunable size between 75 and 200 nm depending on the water addition rate that controls the supersaturation and thus the amount of produced nuclei. In many cases, the aggregation process and ripening precludes long-term stability and colloidal particles have to be isolated rapidly from the solution or stabilized with polymers [49]. Playing on the physicochemical parameters (solvent nature, temperature, and pH) is also a way to tune the size of microparticles to NPs of 1D iron triazole CPs without the help of any stabilizer, for instance, using solvent mixtures where the solvent may coordinate and stabilize short oligomers (as in chlorinated/alcohol mixtures or acetone, see subsequently) [46].

In the case of charged particles, Oswald ripening is strongly limited and particles remain stable for months, even if some reorganization may take place. Charging the surface provides an efficient way of reducing surface tension in water (as observed for oxides) and leads to stable nuclei of smaller sizes. This is the case of PBA and octacyanometallate-based coordination networks that have been reported to display thermal SCO (CsFe[Cr(CN)6]) or CTIST (ACo[Fe(CN)6]y with A = Na, Rb, CsMn[Fe(CN)6]y), light-induced electron transfer (ACoIII[FeII(CN)6]y with A = Cs, Rb, etc.) and light-induced excited spin state trapping (LIESST) effects (CsCu[Mo(CN)8]). For CsxM[M′(CN)6]y it was shown that playing on the stoichiometry of the polycyanometallate and the cations (both transition metal and alkali) it is possible to stabilize sub-100 nm negatively charged nanocrystals by fast addition of an aqueous solution of cations into the polycyanometallate solution, with a size dependence that follows the Irving Williams series [21]. The surface charge is due to the presence of hexacyanometallates and the overall particle is charged as well due to incomplete insertion of alkali inside the tetrahedral vacancies. Moreover, the larger the complexation constant, the lower the solubility and the higher the nucleation rate for similar precursor concentrations. Nucleation is favored by the presence of Cs+ cations that act as templates for the formation of the fcc structure. It was clearly shown that kinetics of nucleation and growth is accelerated in the order Cs+ > Rb+ > K+, Na+ with a decreasing amount of vacancies. Hence Cs+ and Rb+–containing PBAs are the most interesting systems to obtain (1) small particles between 3 and 60 nm and (2) particles with a small amount of hexacyanometallate vacancies. An overall negative charge is obtained (negative ζ potential) and related to the presence of an excess of polycyanometallates that insure the long-term stability of the colloidal solution. Similar features were observed on alkali-containing octacyanometallate-based particles. NPs of CsFe[Cr(CN)6] and AxM[Fe(CN)6]y (M = Co, Mn; A = Rb, Na; and x = 0.2–0.6) were obtained by some of us but despite the good chemical sand structural features (crystallinity, low amount of vacancies, and no linkage isomerism) no cooperative SCO or CTIST was observed to date on PBA when size is reduced to less than 200 nm.

One main advantage of these cyanide-bridged particles is that starting from well-controlled seeds, it is possible to control growth of a defined thickness of the same coordination network or another network that has very similar cell parameters by sequential addition of the precursors in a one-pot process with a perfect predictability over the size, composition, and crystallinity [50]. Importantly, a matrix (polymer, ligand) may be added a posteriori if needed. Even if this strategy is probably the most interesting way for a very systematic study on different sizes of SCO compounds and decorrelate any matrix effect, it is however not applicable to Hofmann clathrates because of the neutrality of the network and neutral [001] facets of the nanocrystals that lead to fast aggregation. Moreover, the smaller complexation constant does not allow the synthesis in diluted conditions. Some combined approaches using PBA seeds for Hofmann clathrates self-stabilized nanocrystals are under progress but there is still no report about self-standing processable NPs less than 100 nm for this family of compounds. A few other template-free strategies have been used by tuning the nature of the solvent (with high dielectric constant) and thus the solubility of the compound, as for PBA (without SCO behavior) in ionic liquids and for iron triazole derivatives in different solvents (see subsequently).

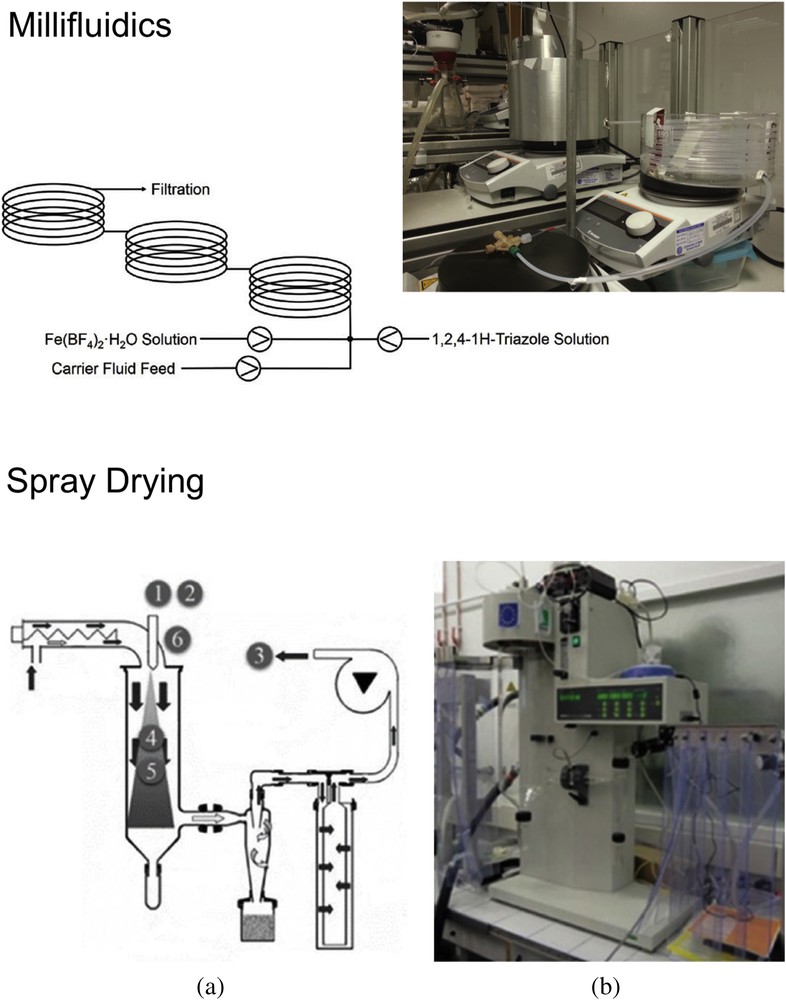

Besides, the continuous production of SCO microparticles and NPs is of technological interest and an attempt has been reported using millifluidics [51]. The use of a milliscale segmented technique (setup with milliscale PTFE tubes and a mixing chamber) has the advantage to produce larger amounts of materials than microfluidic devices (see Fig. 4). One example has been reported recently and shows that using a kinetically regulated automated input crystallizer, a good agreement was obtained with the samples produced by coprecipitation, in the range of 700–1000 nm. Future work is underway in several groups to improve the homogeneity and reduce size using microfluidics. It is also worth mentioning that spray drying used to produce dry powders by rapidly drying with a hot gas has been applied to some iron triazole–based CPs and a mononuclear SCO complex [52]. For the former cases, shape of the microcrystals (spherical) was different from that of the batch synthesis (rods) whereas being similar for the SCO complex, and low crystallinity that affects the SCO properties (see Section 2.2).

Setups for the production of particles by millifluidics (top) and spray drying (bottom). Adapted from Refs. [51,52].

2.1.4 Size and shape analysis

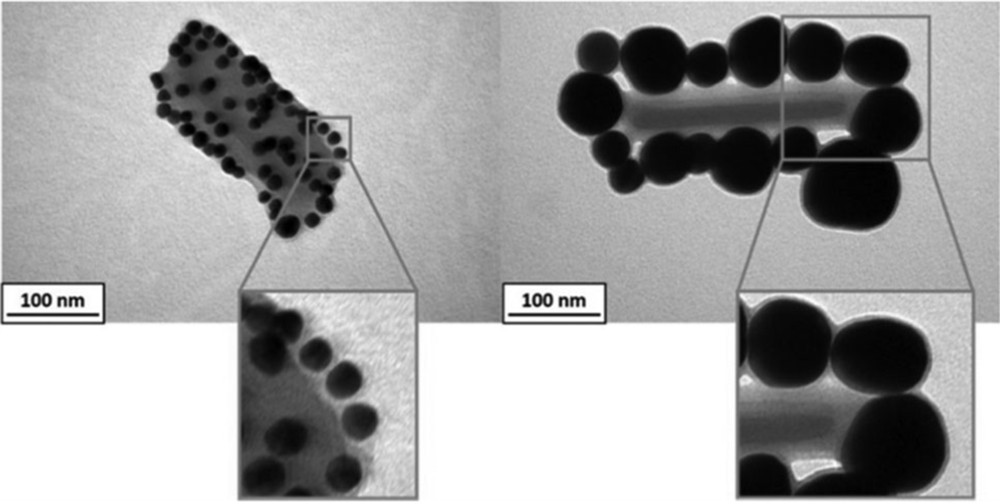

Size and size dispersion are determined using TEM, which provides a direct visualization of the inorganic cores containing high-Z elements that scatter the accelerated electronic beam (typically under a 100–200 kV voltage) with a resolution directly related to the voltage that results in a dark contrast corresponding to the inorganic cores (in bright field mode). The lower metal density of CPs often leads to a much lower contrast as compared with purely metallic NPs that complicates the observation of NPs less than 10 nm; low-dose imaging may be recommended to avoid alteration of the NPs (desolvation and amorphization). Preparation of a routine sample consists in depositing a few drops of the colloidal solution on a TEM copper grid covered with an amorphous carbon layer often reinforced by a polymer (Formvar) and dried before observation. Statistics on the size distribution should be determined (for all dimensions if anisotropic) to provide the average value of the inorganic core together with the standard deviation (e.g., with ImageJ, i.e., a free software). Organic coating does not induce detectable contrast in conventional bright field mode; organic surfactants/polymers may render the inorganic core harder to visualize so that it should be avoided/limited when possible.

The overall diameter of colloidal particles (inorganic core and coating) may be assessed by DLS directly on the colloidal solution. Indeed, by collecting the scattered intensity resulting from the particle interaction with the laser beam, DLS allows estimating the hydrodynamic diameter that includes the core, the coating, and the solvation shell. It is dependent on the ionic force so that a constant ionic force should be maintained (adding salt). Shape of the particles is assumed to be spherical, and in the case of rod-like particles, the diffusion is mainly governed by the length of the rod rather than its width. The technique consists in comparing the resulting diffraction pattern coming from the ensemble of particles in the volume probed by the laser (“speckle”) with time. An autocorrelation function reflects whether the signal change is fast (going fast from 1 to 0). As the translational diffusion coefficient D of a spherical particle decreases with increasing hydrodynamic diameter as stated by the Stokes–Einstein law, smaller particles lead to an autocorrelation function that decreases from 1 to 0 much faster than for larger ones. Fitting of this autocorrelation function leads to the estimated hydrodynamic diameter d(H). The Rayleigh scattering intensity is approximately related to d(H)6; therefore, a large overestimation of the population of larger sizes is obtained from the scattered intensity (that may be reduced if using other representations in volume or number but introducing a large approximation if the refractive index of the coordination network is not well known). It remains the most useful technique to detect the presence of any trace of aggregate in solution. This technique is thus compulsory to check that particles are well individualized, and often the only way to prove that no coalescence has occurred (after recovering from the microemulsion for instance). Another way to check the particles are not aggregated in the solution and determine directly size distribution of the core is to use microtomy on a frozen drop of solution and study them by cryo-TEM. Still DLS is the only technique that provides information on the extension of the organic layer/solvation shell.

2.1.5 Structure and crystallinity

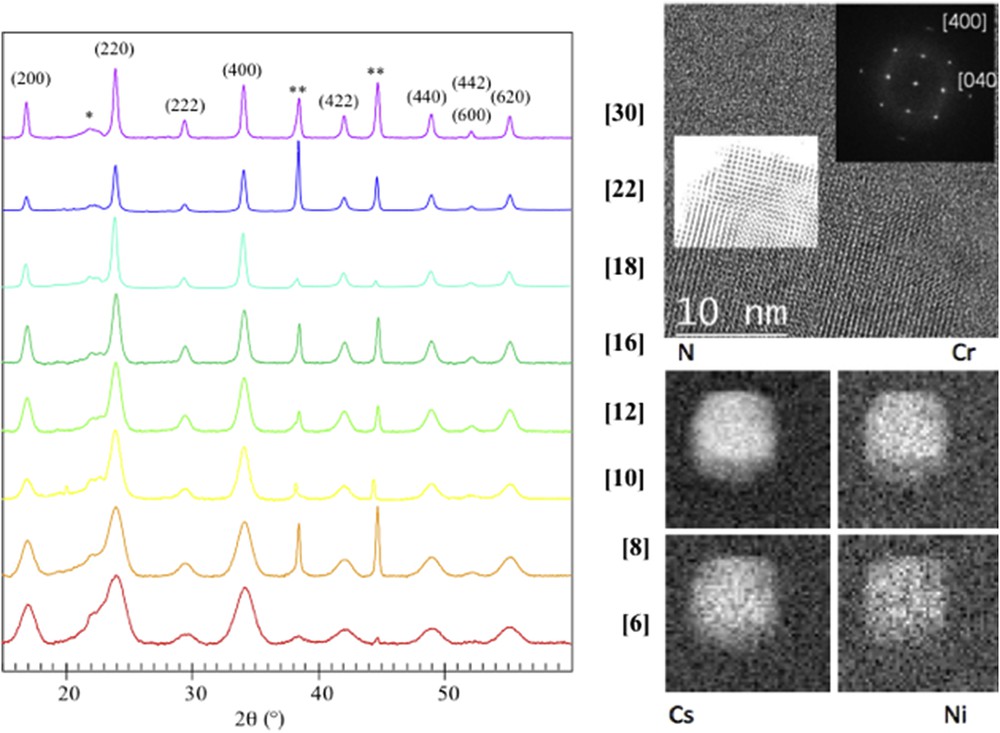

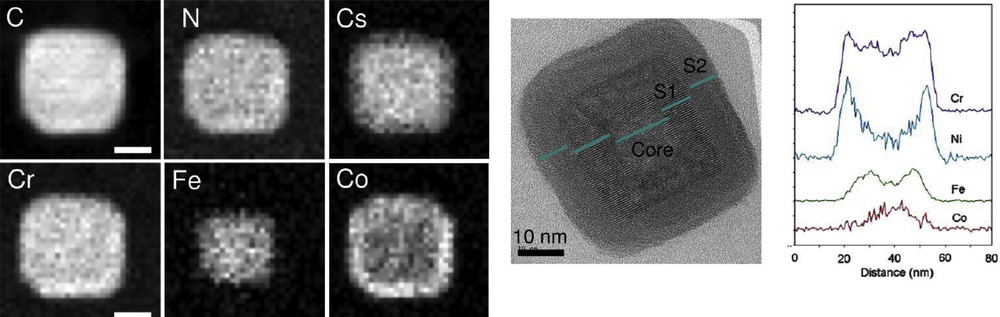

Powder XRD is the routine technique to carry on powders of particles in order to check the structure of the NPs comparing the diffraction peaks with those of the bulk compound. In some cases, it was shown that the nanoscale compounds lead to new polymorphs, which may exhibit completely different SCO phenomena. Moreover, the correlation length that corresponds to the size of crystalline domains may be determined from the full width at half maximum that increases when decreasing size, as stated by Scherrer's law (applicable to sizes up to 100 nm due to the instrumental broadening). This gives a first indication whether the whole particle is crystalline or composed of aggregates of smaller NPs as sometimes seen on iron triazole particles. This often leads to an overestimation as compared with TEM evaluation, because of the higher intensity obtained with larger sizes, and has to be considered as a rough estimation for nanocrystals less than 10 nm where the peaks are large and weak in intensity. Crystallinity may be checked on the local scale by high-resolution electron microscopy where defects such as dislocations may be identified, especially in core–shell heterostructures (see Fig. 5).

Left: X-ray powder diffraction on powder sample of PBA of 6 to 30 nm; Top right local analysis of crystallinity of single particle by high resolution TEM; Bottom right: local composition (N, Cr, Cs, Ni) by energy electron loss spectroscopy by scanning TEM.

2.1.6 Chemical composition

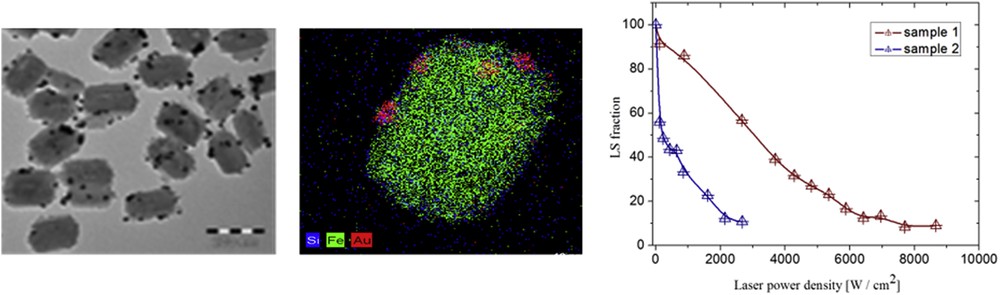

The chemical composition determined preferentially by elemental analysis and/or EDX spectroscopy is crucial to check that the inorganic core remains the same when changing the size of the particles and that the content of organic matter is unchanged (surfactant or any matrix); if the content in surfactant/polymer is not strictly comparable in a series, this may strongly affect the properties and may be misinterpreted. Local composition at the nanometric scale may be carried out by more specific techniques such as EDX spectroscopy used in conjunction with the microscope or electron energy loss spectroscopy (EELS) coupled with scanning transmission electron microscopy (STEM) that provide a local mapping of the different elements and probe the homogeneity of the composition within the nanocrystal. These techniques are very useful to discriminate between core–shell and alloyed structures.

Other techniques commonly used to characterize SCO compounds such as Mössbauer spectroscopy, infrared and Raman spectroscopies, and magnetic susceptibility measurements confirm the information of iron oxidation and spin states that are often strongly altered when decreasing size because of the different environment of iron atoms located at the surface (detailed in Section 2.2).

2.2 State of the art on SCO NPs

All of the reports on SCO NPs can be divided in three families of compounds: the mononuclear complexes with supramolecular interaction also called “molecular complexes”, the 1D chain structure mainly FeII-triazole complexes with various counteranions and substituents beared by the triazole ligand and the 3D Hofmann-like CPs Fe(L)[M(CN)4] (L = bidentate ligand, M = Ni, Pd, or Pt). The elaboration and the SCO properties of nanomaterials from these families of compounds are successively discussed in the 2.2.1, 2.2.2, and 2.2.3 sections. To reach these different nano- and micro-objects, various homogeneous (soluble polymer encapsulation, acid condition, dilution, addition of nonsolvent, etc.) and heterogeneous (reverse micelles, biopolymer encapsulation, etc.) methods have been used. The influence of these approaches on the size, morphology, and SCO properties on the formed particles will be discussed and detailed throughout this section while respecting as closely as possible the chronological order of the publication of articles. A particular attention will be paid on the influence of the size reduction effect on the evolution of the SCO properties for each family of compounds but also comparing the different families.

2.2.1 Fe-triazole chain particles

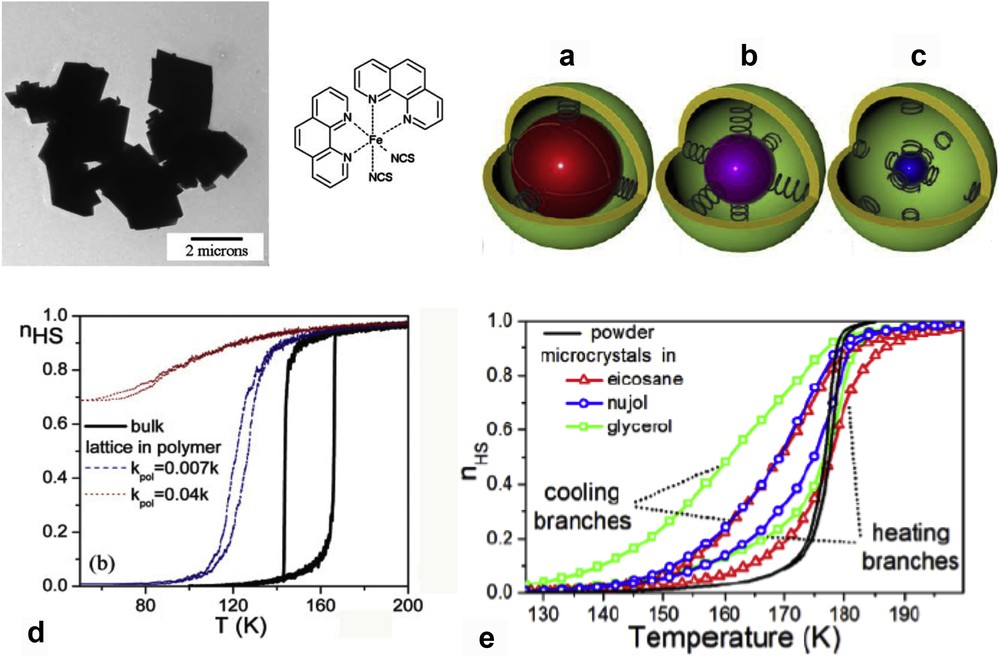

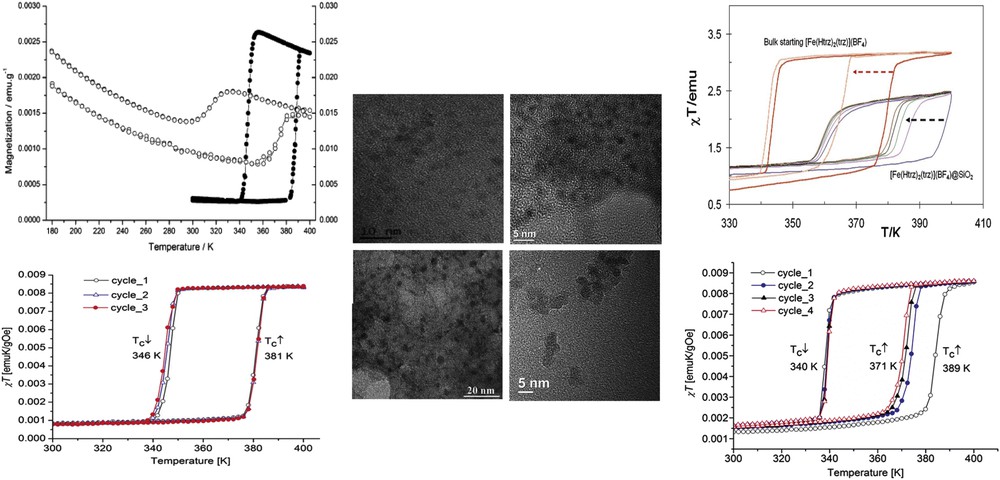

One of the still relevant great challenges underlying the search for such molecule-based functional materials is to produce systems that exhibit switching properties around room temperature and with large hysteresis loop. An important family of compounds presenting such property is the FeII-triazole complexes [53,54] with 1D chain [55,56]. In 1977, Haasnoot et al. [57] reported the first example of such compound, the [Fe(Htrz)2(trz)](BF4) complex (Htrz = 1,2,4-triazole and trz = 1,2,4-triazolato) exhibiting a large hysteresis loop of 50 K centered at 370 K. All of these appealing properties can be exploited into applications only if reduced sized and organized objects are fabricated. Indeed, if we look at the morphology of the elements forming the bulk samples, rather polydisperse and micrometric-sized particles are observed. It is also interesting to note that in comparison with the rather spherical-shaped particles observed for most of these bulk samples of this family [58], a rod-like particles with length ranging from 300 to 800 nm were observed for the bulk sample of the [Fe(NH2trz)3](NO3)2 derivative. In the frame of the study of the size reduction effects on the SCO properties, different methods have been used to obtain controlled size and monodisperse NPs based on these materials.

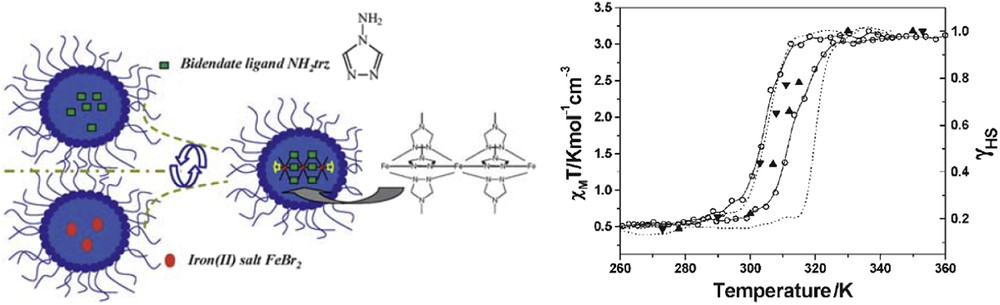

The first results concerning the synthesis of SCO NPs were reported by Létard and co-workers [8,59,60]. These authors reported the observation of a thermal hysteresis loop in NPs of the compound [Fe(NH2trz)3]Br2 (NH2trz = 4-amino-1,2,4-triazole) of ca. 70 nm size obtained by the reverse micelle technique (see Fig. 6). The aforementioned NPs synthesized in the presence of nonionic Lauropal surfactant playing role of both the surfactant and oil maintained the sharp spin transition measured for the bulk powder but with a less pronounced hysteresis loop (T↑ = 311 K and T↓ = 303 K instead of T↑ = 320 K and T↓ = 300 K for the bulk).

Schematic representation of the reverse micelle technique used for the synthesis of [Fe(NH2trz)3]Br2 NPs and magnetic measurements for the 70 nm particles compared with the bulk sample. Adapted from Ref. [60].

Somewhat later, Coronado et al. [40], using a similar approach with sodium dioctyl sulfosuccinate (NaAOT) as a surfactant and octane as an oil phase, have succeeded in synthesizing spherical NPs of the [Fe(Htrz)2(trz)](BF4) complex with a medium statistical size of ca. 15 nm, which exhibited a remarkable 43 K wide hysteresis loop with T↑ = 386 K and T↓ = 343 K. A slight temperature transition move toward lower temperature for the heating branch after successive cycles in contrast to that observed for the bulk sample was also observed. Is it interesting to notice that in this case and on the contrary to that obtained for the [Fe(NH2trz)3]Br2 derivative, no counteranion exchange between the surfactant and complex was observed. Indeed, in the latter case, the presence of the AOT anions in the reaction medium led to the formation of the [Fe(NH2trz)3](AOT)2 derivative [61]. More recently, such a priori not expected exchange reaction was used to synthesize monodispersed 200–300 nm plate-shaped nanocrystals of the corresponding [Fe(NH2trz)3](doe)2 complex (doe = dodecyl sulfonate) undergoing a hysteretic (13 K) abrupt spin transition centered at 317 K [62].

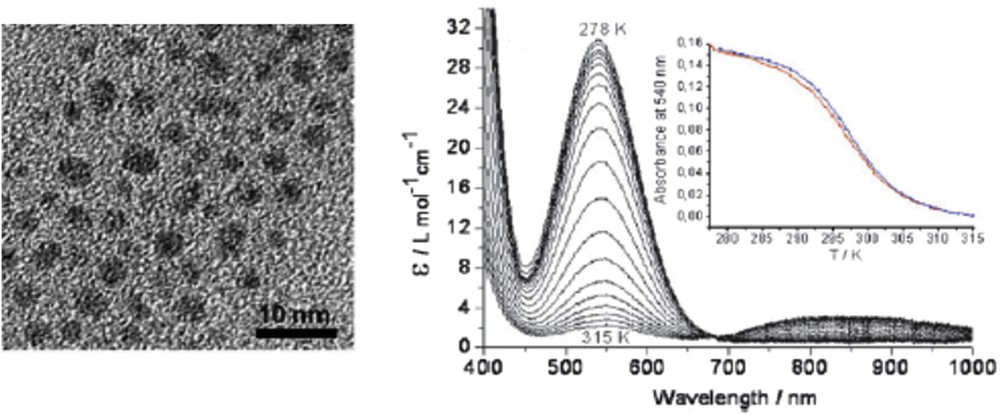

One problem that researchers encounter, however, is that the SCO properties and particle size are measured in separate experiments and in different conditions. Beside the problems associated with polydispersity, the influence of solvent residues and of the matrix surrounding the particles remains difficult to control in many cases. The typical setup involves magnetic property measurement on an aggregated NP powder and TEM measurements on a small amount of particles deposited on a microscopy grid. Although an accurate correlation between size and properties (e.g., on isolated particles) is technically not yet achieved, to get more reliable results a study of the spin state fractions and particle size was realized at the same time using stable monodisperse colloidal suspensions. To this aim, NPs of the [Fe(NH2trz)3](OTs)2 (OTs = tosylate) SCO complex of various sizes (3–40 nm) were synthesized and dispersed in a nonionic Tergitol by the direct evaporation of the polar phase of the microemulsion subsequent to the micellar exchange [63,64]. The average particle size and spin state fraction of such stable limpid purple suspension were determined in rigorously the same conditions by means of DLS and electronic absorption spectroscopy, respectively (Fig. 7). This way it was possible to provide an irrefutable proof that 10 nm NPs of [Fe(NH2trz)](OTs)2 revealed an abrupt spin transition with a hysteresis loop, whereas only a sharp transition with no detectable hysteresis was observed for 3–4 nm particles.

(Left panel) Cryomicrotomy TEM images of 3–4 nm [Fe(NH2trz)](OTs)2 particles in a surfactant matrix. (Right panel) Variable temperature absorption spectra in the visible range and thermal dependence of the absorbance at 540 nm in the cooling (red) and heating (blue) modes. Adapted from Ref. [63].

Moreover, while heating the colloidal suspension, the small NPs evolved into a transparent irreversible gel containing larger size spherical NPs included in the fibrous structure. Using the same water–ethanol/Tergitol binary system (Tergitol plays the role of both the surfactant and oil) and as result of the destabilization of the microemulsion by a nonpolar solvent, larger size spherical NPs ranging from 80 to 1500 nm preserving the SCO properties of the bulk were also obtained. To investigate the versatility of this approach other representatives of the [FeII(R-trz)3](anion) SCO family have been investigated as well. For this aim, [Fe(Htrz)2(trz)](BF4) and [Fe(NH2trz)3](Cl)2 NPs were prepared using the same conditions of microemulsion. However, in these cases, the mixture of the two initial independent microemulsions is unstable and leads to rapid precipitation of 85 and 32 nm NPs, respectively—contrary to the [Fe(NH2trz)3](OTs)2 complex. Comparison of the obtained particle sizes reveals that the [Fe(NH2trz)3](Cl)2 and [Fe(Htrz)2(trz)](BF4) NPs should be formed mainly in the micelles and the particle extraction stage (solvent precipitation) does not affect considerably the particle size in these cases. This finding is in agreement with the NP sizes obtained in Ref. [60] for the [Fe(NH2trz)3](Br)2 complex. On the contrary, the water solvated oligomeric species stabilized for the [Fe(NH2trz)3](OTs)2 complex in the micelles form the NPs in the precipitation stage. Thus the change in the chemical composition and the reaction solvent can influence on the nucleation and the particle growth processes for the synthesis of the [FeII(R-trz)3](anion) complexes.

Study of particle size of [Fe(NH2trz)3](Br)2 on its SCO properties was reported by Forestier et al. [65]. For particle sizes of 50 and 30 nm obtained with different ω factors (ω tends to the solvent/surfactant ratio), a relatively gradual thermal SCO occurs without clear existence of thermal hysteresis although the equilibrium temperature of the transition is almost unaffected by the decrease in the size of the NPs. The authors suggested by means of powder XRD analyses that the bistability regime implies the presence of at least five interacting coherent domains. Size effects in [Fe(NH2trz)3](Br)2 SCO NPs with rather broad size distributions were also investigated by first-order reversal curves' magnetic measurements [66]. The study of thermal transition of such surfactant-coated NPs with average diameter d in between 30 and 110 nm revealed the presence of reversible contributions expected from particles smaller than the critical size dC associated with the collapse of the hysteresis loop. Thanks to the reversibility property the dC values ∼45–50 nm were determined. A differential interference microscope operating in transmission mode was used to study the SCO properties of single isolated [Fe(NH2trz)3]Br2 microparticles [67]. The comparison of the thermal hysteresis loop of several isolated microparticles demonstrates that the warming branch clearly appears more abrupt than the cooling branch and in fact, the gradual spin transition recorded for the macroscopic material does not simply result from the superposition of sharp hysteresis loops of individual particles.

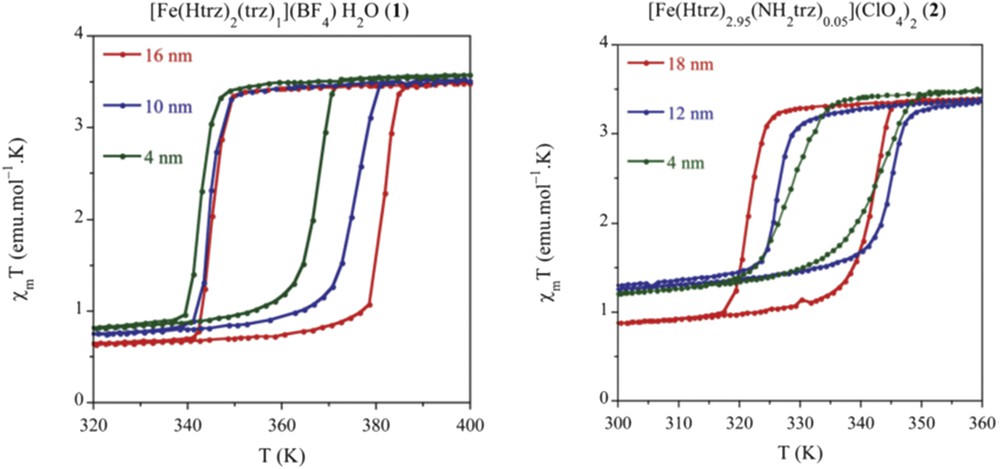

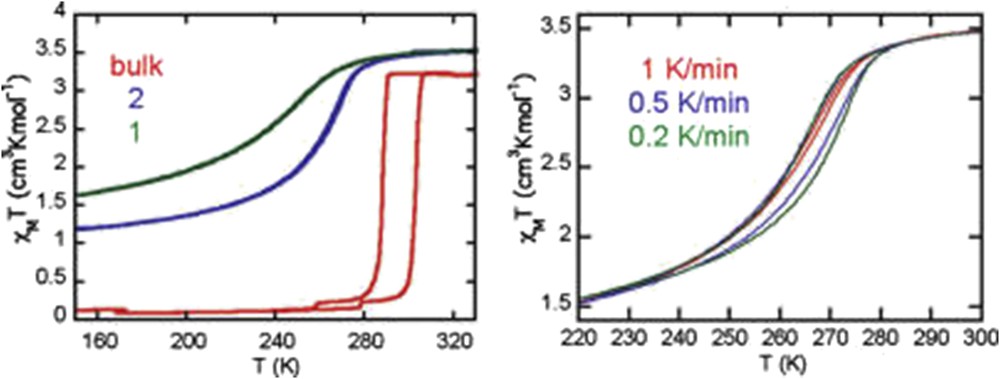

The size reduction effect on the SCO properties for the [Fe(Htrz)2(trz)](BF4) NPs was also investigated. By changing the ω factor, Galán-Mascarós et al. [68] succeeded to tune the mean size of the NPs down to 6 ± 3 nm in diameter with a narrow size distribution. A narrower 29-K wide hysteresis was found in this case (centered around 357 K), with a higher high-spin (HS) residual fraction (33%). This work was extended with a fine control of the ω factor in between 5 and 11.5 (limit of the stability of the microemulsions) affording NPs in the 4–18 nm range for [Fe(Htrz)2(trz)](BF4) and [Fe(Htrz)2.95(NH2trz)0.05](ClO4)2 complexes [69]. The latter material has been prepared with the aim of shifting the SCO phenomenon toward room temperature (Fig. 8). Importantly, for the different sizes investigated, the NPs exhibit the characteristic abruptness in the spin transition, with a significant decrease in the hysteresis width by progressive reduction in the size. Thus, relatively large hysteresis loop has been preserved even for NPs of only 4 nm (with value of 24 and 13 K for the BF4 and ClO4 derivative, respectively).

Thermal hysteresis of the magnetic susceptibility (per mole of Fe) of various size [Fe(Htrz)2(trz)](BF4) and [Fe(Htrz)2.95(NH2trz)0.05](ClO4)2 NPs. Adapted from Ref. [69].

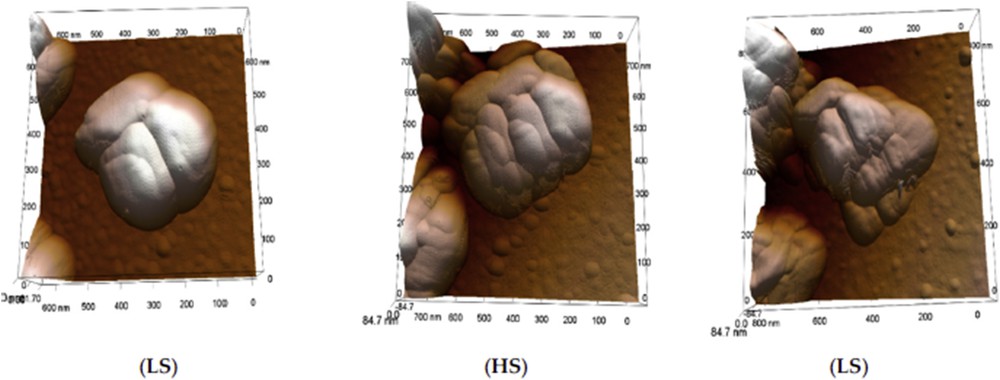

The effect of ligand substitution on the SCO properties and shape of [Fe(Htrz)2(trz)](BF4) NPs was also investigated [70]. It has been shown, as previously observed for the bulk material, that the transition temperature can be gradually shifted toward room temperature, with respect to the increasing 4-NH2-triazole quantity inclusion, reducing hysteresis width but still with abrupt spin transition. Moreover, increasing the 4-NH2-triazole quantity inclusion, the morphology of these NPs is changing also from platelet to rod-like. Such tendency to obtain platelet rather than spherical particles for this particular [Fe(Htrz)2(trz)](BF4) complex was clearly demonstrated by Bartual-Murgui et al. [71] synthesizing a series of different size NPs playing with the ω factor of the water/AOT/octane ternary system. One hypothesis to explain the discrepancy concerning the reported shape of the particle is related to the residual surfactant around the NPs. It seems that the presence of the surfactant induces the rods to be packed vertically on the substrate suggesting a false spherical shape. It was also shown that the presence of the surfactant tends to increase the cooperativity in the material. Indeed, the removal of the surfactant leads to the decrease in the width of the hysteresis loop of ca. 15 K. On the other hand, the hysteresis width is found to increase linearly with the width of the particles until reaching values close to 40 K (raw NPs) and 20 K (washed NPs) for 20 nm NPs. Such tendencies were more recently confirmed by the rationalized study of Moulet et al. [72], which also highlighted the decrease in T↑ while T↓ is barely affected upon the NPs size reduction. These syntheses using Tergitol as surfactant and modifying both the reaction temperature and time afforded rod particles with length varying from 75 nm to 1 μm. In this study, the evolution of the crystallinity and the coherent-domain morphology was also reported including the effect of a large number of repetitive SCO thermal cycles [73]. Structural fatigability was observed at the scale of the coherent domains. A few hundred thermal SCO cycles were able to destroy the crystalline aspect of the material and such degradation in the crystalline quality was associated with a break in the [Fe(Htrz)2(trz)]+ chains and confirmed by similar observations on the [Fe(NH2trz)3](NO3)2 derivative. On the other hand, a thermal treatment allows us to recover a better crystallinity increasing the size of the coherent domains [74]. The morphology change associated with the spin transition of similar isolated particles synthesized in a water/Triton X-100/cyclohexane ternary system was also analyzed using variable-temperature AFM (Atomic Force Microscopy) in amplitude modulation mode [75]. Significant microstructural reorganization of the particles during the low spin (LS) to HS transition, which involved a volume expansion, grain boundary changes, and a certain degree of separation of the nanocrystallites, was observed (see Fig. 9). These changes particularly important during the first switching event and only partially reversible during the reverse (HS to LS) switching can explain the observed shift of the LS to HS transition temperature between the first and second heating cycles.

AFM height images of a [Fe(Htrz)2(trz)](BF4) particle acquired in different spin states at 358 K (in the hysteresis loop) over a complete thermal cycle. Adapted from Ref. [75].

The stability tests of the SCO properties for the [Fe(Htrz)2(trz)](BF4) complex were also carried out for powder NP samples and electronic devices by reflectivity and electrical measurements, respectively [76]. The key finding is that the spin transition is robust to a large extent, because the powder compound can be stored for several years and the hysteresis associated with the SCO can be preserved even after several thousand thermal switches in ambient atmosphere although a progressive reduction in the width of the hysteresis loop is observed from the ca. 500th cycle. Concerning the electrical devices, the spin transition remains reproducible over several tens of cycles but the measured current decreases continuously. Such device characteristics changing with thermal cycling might be attributed to a change in the electrical contact with the interdigitated electrodes. Indeed, the device was prepared by dielectrophoresis depositing a drop of a suspension of the anisotropic [Fe(Htrz)2(trz)](BF4) NPs under the gold electrodes. Other examples have reported the used of suspended NPs to elaborated SCO thin films or nanopatterns. In particular, homogeneous thin film maintaining the bistability properties was obtained from surfactant free, not dried (wet with ethanol), and dispersed in various solvent [Fe(Htrz)2(trz)](ClO4)2 NPs [77]. A soft lithographic technique was also implemented to elaborate homogeneous micropatterns and nanopatterns of SCO NPs over a large area [78]. Microtransfer molding was used with an aprotic solvent (normally difficult to implement because it generates the swelling of the polydimethylsiloxane stamp) to elaborate patterns containing [Fe(NH2trz)3](OTs)2 NPs.

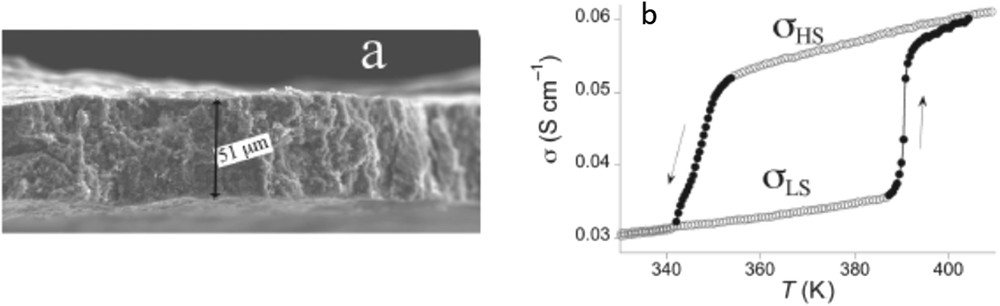

A particular attention was paid to the electrical properties of [Fe(Htrz)2(trz)](BF4) nano-objects upon SCO [79]. Using [Fe(Htrz)2(trz)](BF4) NP powder sample or the corresponding microparticles and NPs integrated in between interdigitated electrodes by dielectrophoresis, Rotaru and co-workers [80,81] reported the spin state dependence of electrical conductivity. In both cases, the thermal variation in the measured current revealed a wide hysteresis loop centered around 370 K with the LS state being more conductive. Using similar strategy, these results were confirmed by Dugay et al. [82] The study of the metal substitution effects on the charge transport of [Fe1−xZnx(Htrz)2(trz)](BF4) NPs revealed a strong overall decrease in conductivity with increase in Zn concentration suggesting that the ferrous ions participate directly in the charge transport mechanism [83]. Photoconductivity experiments on [Fe(Htrz)2(trz)](BF4) micrometric rods were also carried out [84–86]. Prins et al. [87] showed the possibility of addressing single [Fe(Htrz)2(trz)](BF4) NP deposited between gold electrodes with an electrode gap of 5–10 nm. By plotting the conductance (I/V) of the device at 0.4 V as a function of temperature, a hysteretic behavior similar to the one obtained in the magnetic susceptibility measurements was found. Photoswitching experiments on [Fe(Htrz)2trz](BF4) NPs synthesized in microemulsion in the presence of Tergitol were also realized [88]. Whatever the temperature of the compound, outside and within the thermal hysteresis loop, the photoswitching from the LS to the HS state is achieved in ca. 10 ns.

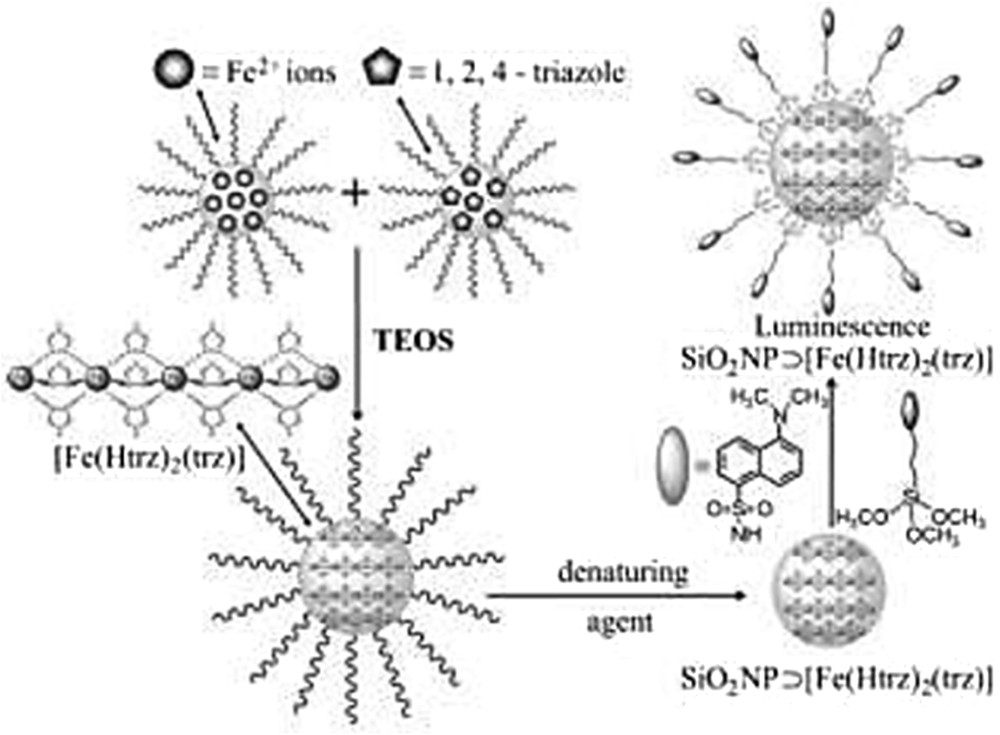

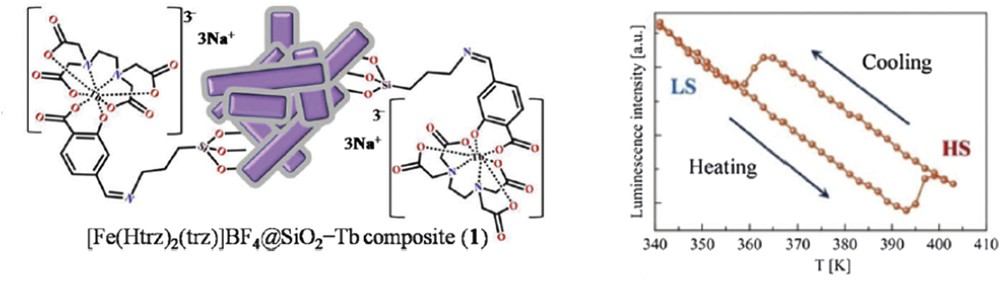

Alternatively, nanocomposite systems integrating an SCO functionality have been designed by embedding SCO NPs within mesoporous silica matrices. First report concerns the inclusion of preformed [Fe(Htrz)2(trz)](BF4) complex in a xerogel using a one-step method [27]. The silica precursor mixed with a sonicated complex suspension afforded, after the gelation, aging, and drying processes, monolith or thin film containing the SCO compounds. The HRTEM (High Resolution Transmission Electronic Microscopy) analysis of the [Fe(Htrz)2(trz)](BF4)@SiO2 film and monolith revealed well-dispersed NPs of the Fe complex in the SiO2 matrix, with diameter ranging from 2 to 5 nm. The composites undergo incomplete SCO behavior with temperature transition shifted toward high temperature in comparison with the bulk material mainly attributed to the SiO2 matrix effect. In 2013, Durand et al. [30] reported the preparation and characterization of a 3 nm SCO NP–silica nanocomposite using a two-step nanocasting synthetic method by confined growth of NPs of the SCO CP [Fe(Htrz)2(trz)](BF4) using an impregnation technique in a preformed silica xerogel matrix with well controlled porosity. The temperature dependence of the magnetization of the FeHtrz–silica nanocomposite indicated an uncompleted reversible spin transition with a hysteresis loop of 65 K width larger than that of the bulk sample. Again, it was assumed that the interactions between the NPs and the rigid silica matrix play a key role in the maintaining of a hysteresis because larger size dispersed NPs of the same complex obtained by the reverse micelle technique exhibit a much reduced hysteresis.

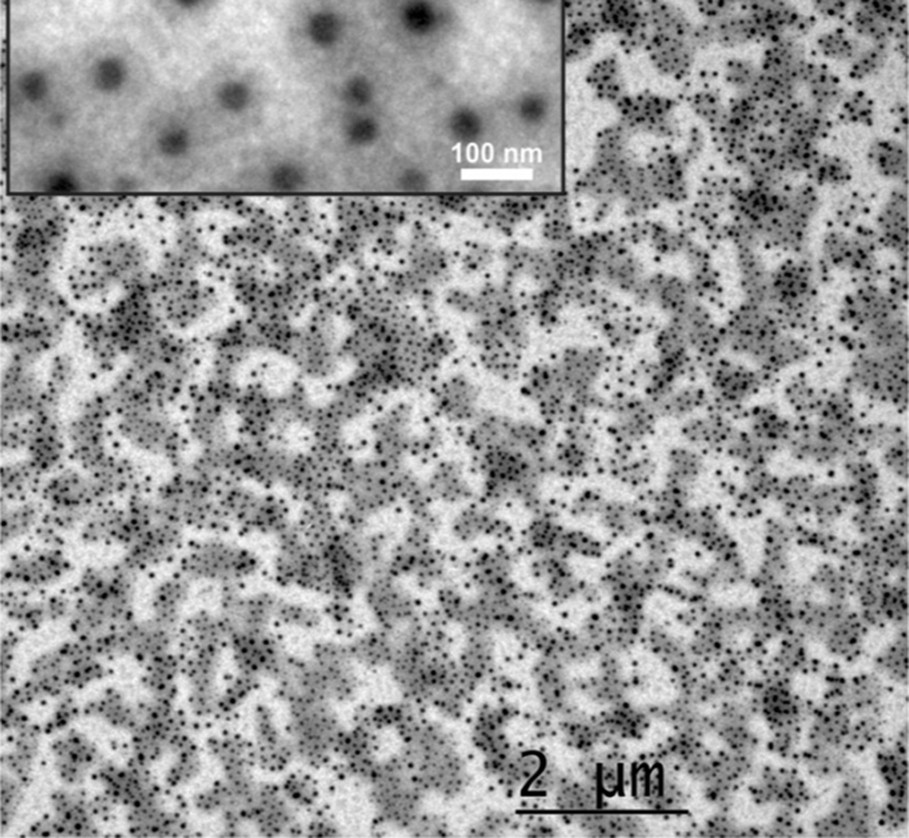

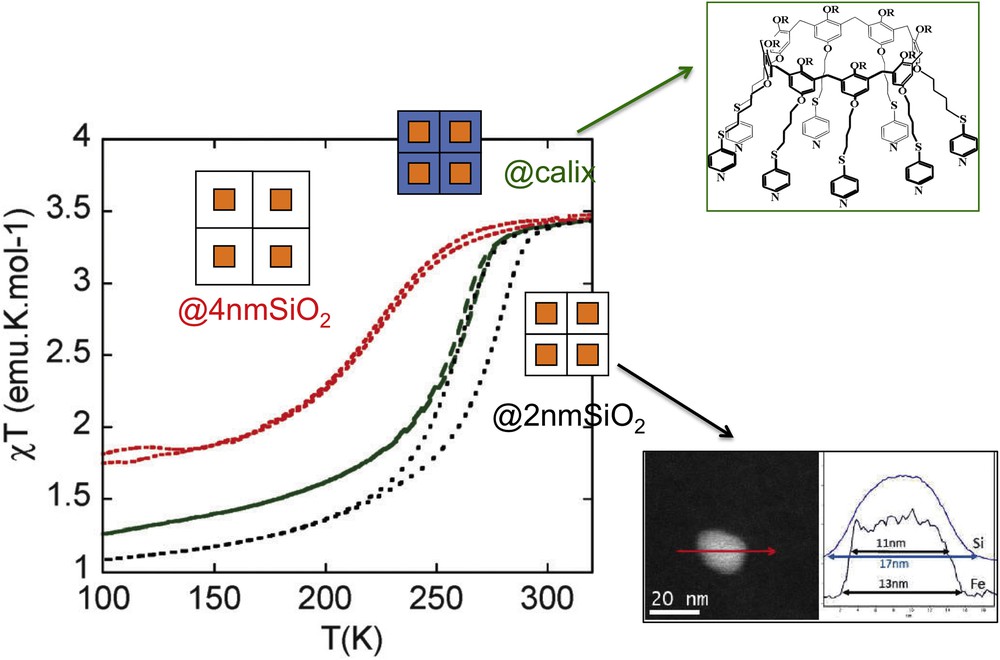

More recently, similar strategy was used to incorporate 2 nm cross-section nano-objects of the two polymorphs [Fe(Htrz)2(trz)](BF4) and [Fe(Htrz)3](BF4)2 in a commercial MCM-41 hexagonal silica matrix [89]. The Mössbauer, DC magnetic, and optical reflectivity measurements demonstrated a strong matrix effect only for [Fe(Htrz)3](BF4)2@MCM, whereas the matrix effect for [Fe(Htrz)2(trz)](BF4)@MCM is much weaker. The explanation was associated with the presence of water for the former polymorph and suggests that water is important as a “pressure mediator” for delivering the “hydrostatic pressure” to induce a significant matrix effect (see Section 2.3). SCO@SiO2 NPs were also synthesized using a reverse micelle technique in the presence of the precursor of the silica [90]. Such particles constitute a platform for the elaboration of various hybrid NPs (fluorescent, plasmonic) developed in the following section 3. SCO nanorod arrays were also achieved by self-assembly on a sulfonated cation-exchange polymer resist, which acted as a template to direct the growth of the nanorod arrays. By increasing the immersion time of the resin in the precursor solutions, resin beads were covered by perpendicular rods with size increasing from 250 to 750 nm [36]. The author speculated that the nucleation and growth mechanism of the SCO nanorod arrays is as follows: (1) the resin beads act as a nanoporous template with internal channels, which provide numerous ion-exchange sites for Fe2+ and H+ ions; (2) the triazole organic ligands and BF4− anions react with the Fe2+ cations bound to sulfonic acid groups on the surfaces of the resin beads to generate the nucleation sites of the SCO nanorods; and (3) at the same time, the Na+ cations diffuse into the internal channels of the resin to exchange with Fe2+ cations, and the exchanged Fe2+ cations are released into the solution slowly and promote the consequent growth of the SCO crystal nucleus to form nanorod arrays.

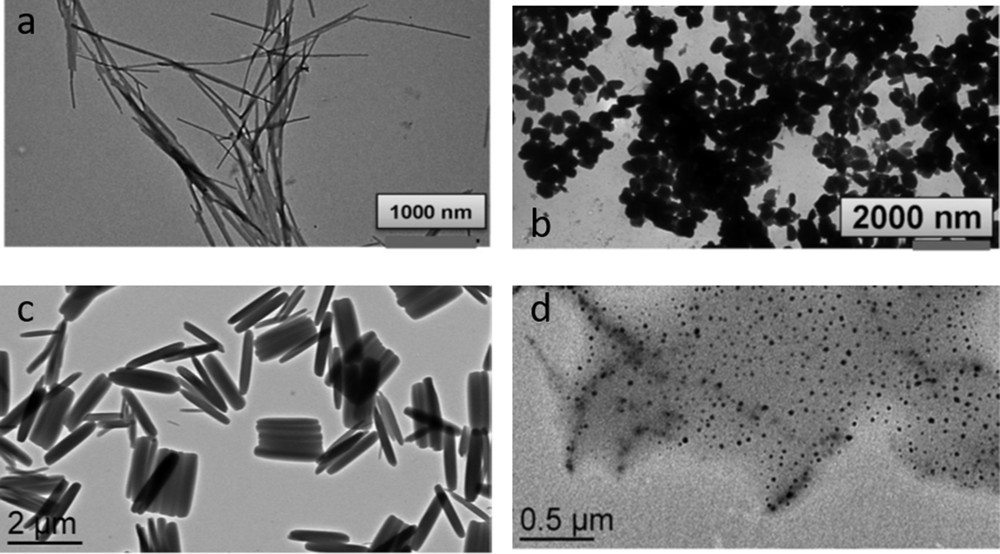

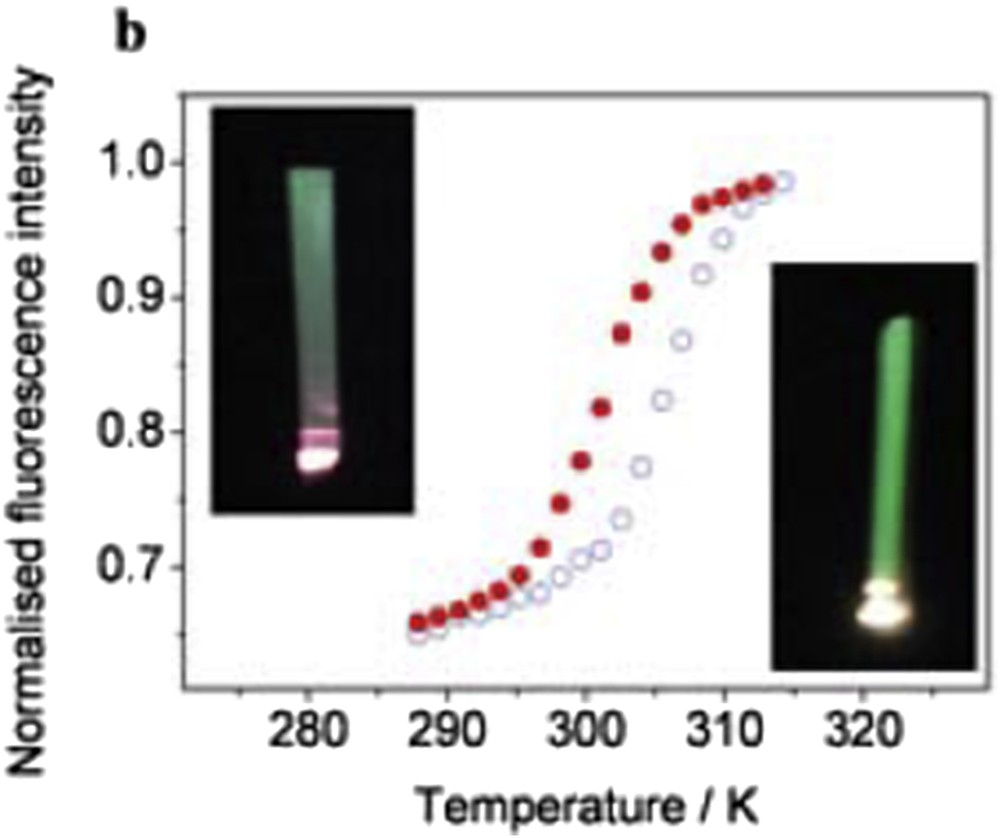

SCO properties are often highly sensitive to minute aspects of the synthetic conditions, and it is of particular interest to investigate this question in the case of nano-objects. Following this idea, synthesis of [Fe(hptrz)3](OTs)2 (hptrz = heptyl-triazole) NPs by both heterogeneous (reverse micelles) [91] and new homogeneous [46] approaches using or not using different stabilizers (surfactants and polymers) was also reported. Nano-objects with various morphologies were obtained, and the relative (dis)advantages of the different approaches were discussed. The modification of both the ω factor of a water/tergitol/hexane ternary system and the concentration of the reagents does not influence drastically the size of the NPs: the average size varying from 35 to 70 nm [91]. In comparison with the bulk sample, the size reduction and the aggregation effects appear to be rather weak on the spin transition behavior. On the other hand, homogeneous synthetic pathways to obtain SCO micro- and nano-objects can bring several advantages, including (1) in contrast to the reverse-micelle technique, this process is simple and versatile, not only because various polar and nonpolar solvents can be used, but also because the whole procedure does not imply the presence of a critical step that influences the final material, such as the destabilization of the micelle phase by an additional solvent. (2) The quantity of the polymer and the solvent used for the synthesis is lower than those used in the reverse-micelle method. As a consequence, measurements of the properties are facilitated by the high concentration of the active species in the matrix. (3) The shape and size of the nano- and micro-objects can be different to those that are elaborated with the microemulsions. (4) The doping of the SCO polymer with an organic molecule (e.g., a fluorescent agent) can be more easily controlled, owing to the absence of two phases with different polarity that could provoke the undesired migration of the guest species, as in the case of a microemulsion. Following this approach, particles of the [Fe(hptrz)3](OTs)2 derivative were synthesized in the presence of various polymeric compounds as Triton X-100 (with a hydrophilic polyethylene oxide group and a hydrocarbon lipophilic group), TOPO (trioctylphosphine oxide), PVA (polyvinyl alcohol), and PEGs (polyethylene glycols) [46]. Whatever the encapsulating polymer used, quite large size particles ranging from 150 to 1500 nm maintaining the SCO properties of the bulk (T↑ = 318 K and T↓ = 308 K) were obtained (Fig. 10). Importantly, attempts to obtain smaller-sized objects by modifying the nature or the concentration of the polymers were unsuccessful. Nevertheless, instead of the rather spherical shape encountered for the reverse micelle syntheses, more anisotropic shapes (rods and plates), depending on the solvent used, were obtained in such homogeneous media. Here 250 nm particles of the [Fe(hptrz)3](OTs)2 derivative synthesized in the presence of PEG were used to probe the sensitivity of a novel SQUID (Superconducting Quantum Interference Device)-like magnetometry device prototype working at room temperature [92]. In this work, an ensemble of [Fe(hptrz)3](OTs)2 NPs with a volume of ca. 3 × 10−3 mm3 has been investigated and was found to give rise to a modulated voltage signal of about 0.55 mV, which reflects the SCO properties.

TEM images showing various sizes and shapes of [Fe(hptrz)3](OTs)2 NPs obtained in homogeneous media. (a) Synthesis in the presence of Triton X-100; (b) synthesis in the presence of PEG; (c) slow precipitation from an oligomer CHCl3 solution; and (d) fast precipitation from a fresh oligomer solution with PEG. Adapted from Ref. [46].

The next step was to find a polymer-free synthetic pathway for the elaboration of SCO NPs, motivated by the expectation that the molecules on the surface are one of the key factors in influencing the spin transition in the NPs. It was possible to stabilize short oligomer solutions of the same [Fe(hptrz)3](OTs)2 compound without embedding it in the polymer or surfactant, by performing the reaction in a specific solvent mixture [46]. The reaction between [Fe(H2O)6](OTs)2 and hptrz in chlorinated organic solvents, such as CHCl3 or trichloroethylene, in the presence of alcohols (up to 5% v/v) yielded relatively stable solutions of a low-level “polymerization” SCO complex. The addition of alcohols effectively prevents the gelation of the complex. The alcohol can play the role of a terminal ligand, slowing down the growth of the oligomers into larger structures. The alcohol has an exclusive influence on the stabilization of the oligomer solution without gelation; in contrast, the use of DMF or DMSO provokes the direct formation of a fibrous gel structure. A few seconds after mixing the reagents, the color of solution turns pink, thus indicating the formation of the LS complex. DLS measurements as a function of time show the presence of 6.5(±2) nm objects in fresh solution and their growth into microstructures over 24 h. Slow growth of the oligomers occurs within a few hours of mixing the reagents until the mean size reaches 8.5 nm; then, a fast and spontaneous formation of about 400 nm crystals takes place with a subsequent gradual increase to about 1400 nm. Alternatively, the addition of PEG-3350 chloroform solution to the initial and diluted oligomer solution results in the formation of colloidal solutions of small NPs of 23(±5) and 6.2(±1.8) nm, respectively (Fig. 10). The properties of such smaller NP studied by optical-reflectance measurements revealed a transition temperature shift of approximately 10 K; the more important observation being the gradual manner in which the spin transition occurs.

Such types of oligomer solution can be extremely useful for the preparation of SCO thin films by spin coating onto different substrates and for the elaboration of nanopatterns by means of soft lithography, as recently reported [93–95]. The importance of obtaining stable nano-objects without the presence of large amounts of additives has been underlined for the surface deposition and patterning of the particles. Indeed, dilution of particles in a surfactant can be a serious obstacle in the study of the SCO properties, and in particular, the electrical and optical properties of the particles can be completely masked by the matrix.

A similar surfactant-free homogeneous approach was used to synthesize homochiral coordination NPs of [Fe(NH2trz)3](l-CSA)2 (NH2trz = 4-amino-1,2,4-triazole, l-CSA = l-camphorsulfonate) [96]. Acetonitrile was used as a solvent and stabilizer to prevent the aggregation of the ca. 50 nm NPs. The introduction of the chiral anion to the coordination framework makes these NPs display specific chiro-optical (circular dichroism) properties that are different in HS and LS states.

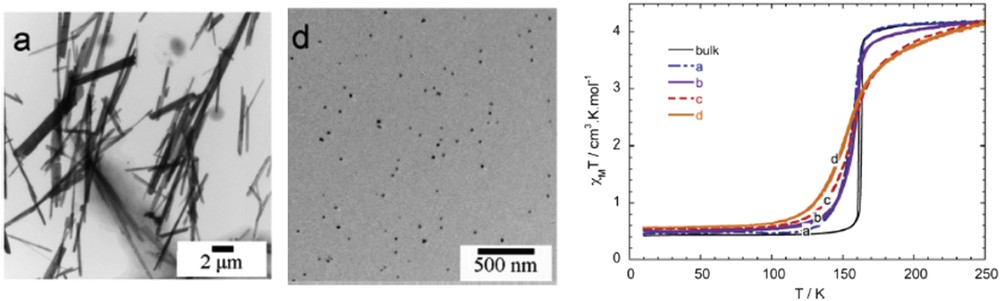

An original homogeneous acid medium method was also used to synthesize controlled size surfactant/polymer-free nanorods and microrods based on the BF4 (tetrafluoroborate) and CF3SO3 (triflate) derivatives of the Fe-triazole family of compounds [97,98]. The control of the size was realized by modifying the acid concentration. In the case of the BF4 derivatives, all of the physical characterizations revealed a correlation between the size of the particles and their composition, the smaller rods correspond to the [Fe(Htrz)2(trz)](BF4) complex with a spin transition localized at high temperature (T1/2 (↓) ≈ 352 K and T1/2 (↑) ≈ 397 K), whereas the longer ones correspond to the fully protonated ligand [Fe(Htrz)3](BF4)2·3H2O derivative, which presents a spin transition just below room temperature (T1/2(↓) ≈ 265 K and T1/2 (↑) ≈ 278 K for the dehydrated compound) [97]. In fact, high concentrations of acid, which preclude the deprotonation of the Htrz ligand associated with a slow evaporation speed of the complex solution, lead to the slow stabilization of the [Fe(Htrz)3](BF4)2·3H2O long rod-shaped particles, whereas short rod-shaped [Fe(Htrz)2(trz)](BF4) particles are obtained for low acid concentrations. Thus, it is demonstrated that not only the size but also the morphology of the objects for a considered material can be tuned. A similar homogeneous acid condition was used for the elaboration of highly anisotropic acicular rods of the CF3SO3 derivatives as well [98]. Syntheses in the absence or in the presence of low concentration of acid allowed us to stabilize rod-shaped particles of the [Fe(Htrz)2(trz)](CF3SO3) derivative, which presents a rather low temperature SCO behavior as compared with other compounds of this family with T1/2(↓) ≈ 162 K and T1/2(↑) ≈ 166 K for the dehydrated form. In contrast, incorporation of larger concentration of acid as for the BF4 derivative led to the precipitation of microrods of the [Fe(Htrz)3](CF3SO3)2 form. This new compound presents a large hysteresis loop of 50 K perfectly centered at room temperature (T1/2(↓) ≈ 278 K and T1/2(↑) ≈ 327 K). Such properties are very scarce and even unique for shaped materials. Indeed, although hysteretic SCO at room temperature is a prerequisite to go toward several applications, the possibility to obtain regular and organized nano- and micro-objects is also crucial. In fact, such simple experiments led to the elaboration of already-shaped SCO objects with very appealing properties, which will be certainly beneficial to undertake the relevant great challenges concerning both fundamental and applied perspectives. In particular, these very high aspect ratio bistable objects could be really useful using soft lithographic approaches or the dielectrophoresis to understand the spatiotemporal behaviors and the transport properties of organized individual objects, which constitute one of the foremost paradigms in molecular electronics. Moreover, the largest measured “real” room temperature bistability reported for these objects is very promising for practical application in the fields of memory devices, display devices, inkless paper, and microelectromechanical systems.

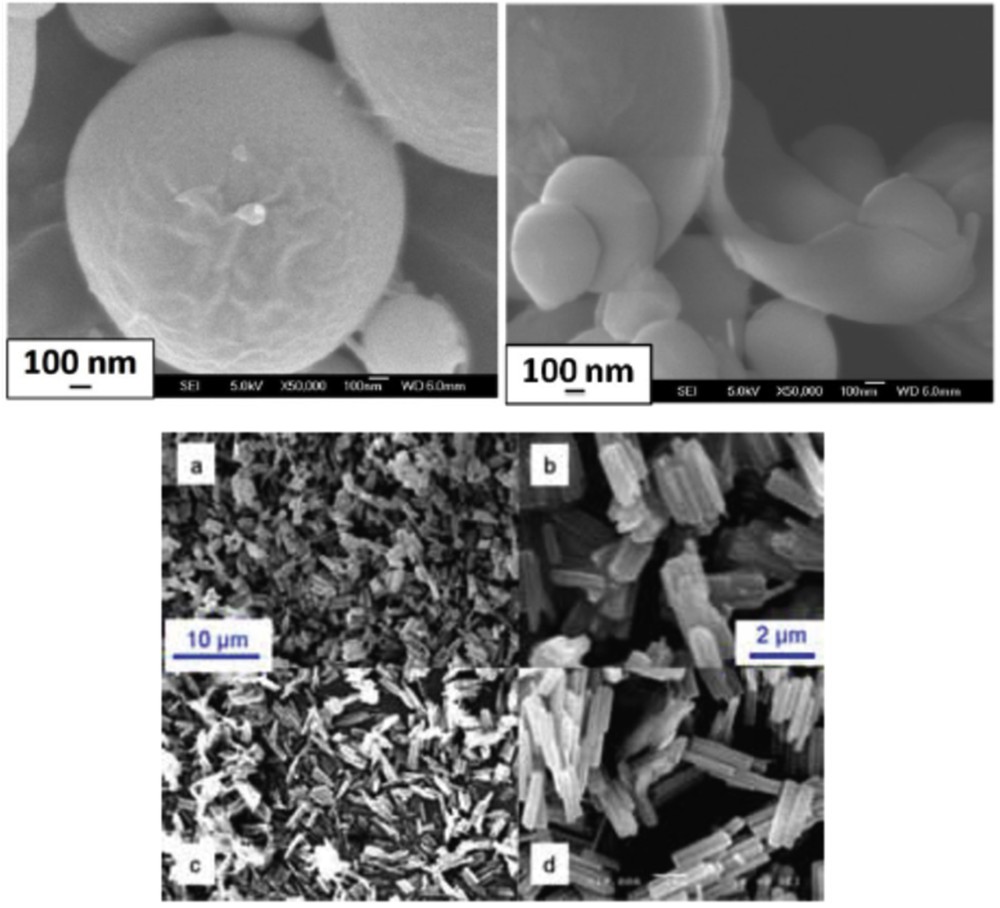

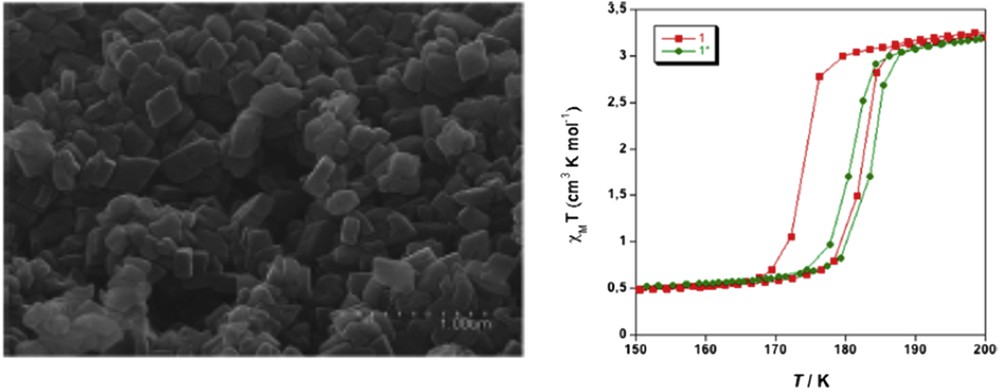

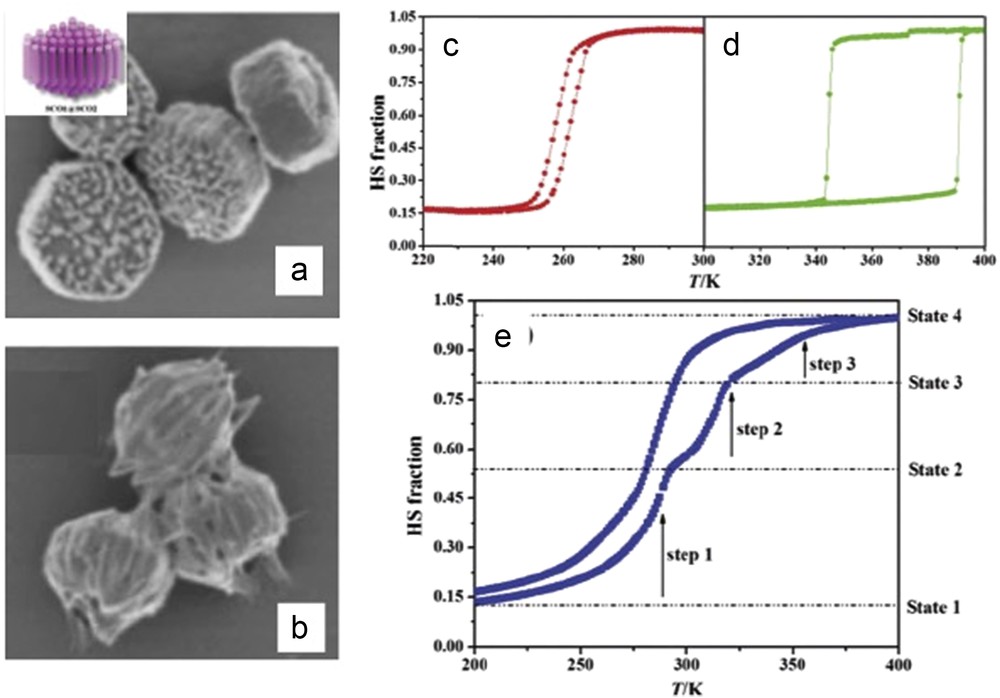

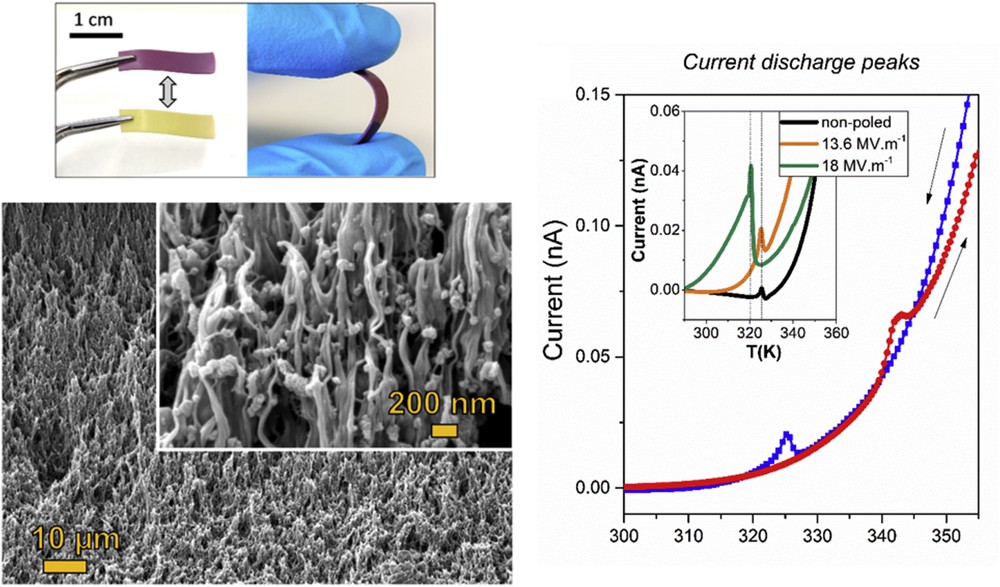

Different SCO NP morphologies were also obtained using a spray-drying method, which is a method to transform aqueous solution into powders [52]. In the case of the CP [Fe(Htrz)2(trz)](BF4) (Fig. 11), the SCO properties of the spherical particles differ from those of the referenced materials, in the sense that SCO is more gradual and incomplete, in adequacy with a poor crystallinity. It is interesting to notice that such techniques commonly used by food and pharmaceutical industries permit to produce in a simple manner a large quantity of material. In this research axe, fluidics methods have become well established as the benchmark method of NP production. Very recently, millifluidics methodology was used to control and increase the NP production. Thus, the first flow synthesis of [Fe(Htrz)2(trz)](BF4) particles in a milliscale segmented flow crystallizer has been reported (Fig. 11) [51].

Scanning electron microscopy (SEM) images of (Fe(Htrz)2(trz))(BF4) synthesized by spray drying (top) and millifluidic methods (bottom). Adapted from Refs. [51,52].

The ensemble of results concerning compounds of the triazole family seems to indicate that the evolution of the SCO properties is not only dependent on the size but also critically on the chemical nature of the compounds and certainly more precisely on the structural arrangement of the chains, which is influenced by the nature of the ligands and that of the counter anions and (in certain cases) by solvent molecules. Unsubstituted triazole ligand in [Fe(Htrz)2(trz)](BF4) and tosylate OTs counter anion in both [Fe(NH2trz)3](OTs)2 and [Fe(hptrz)3](OTs)2 seem to favor strong interactions between the adjacent chains, presumably by means of hydrogen bonds possibly through solvent molecules. This cooperative effect could explain the maintaining of the first-order spin transition in these compounds even at the nanometric scale.

2.2.2 Three-dimensional Hofmann-like clathrate NPs

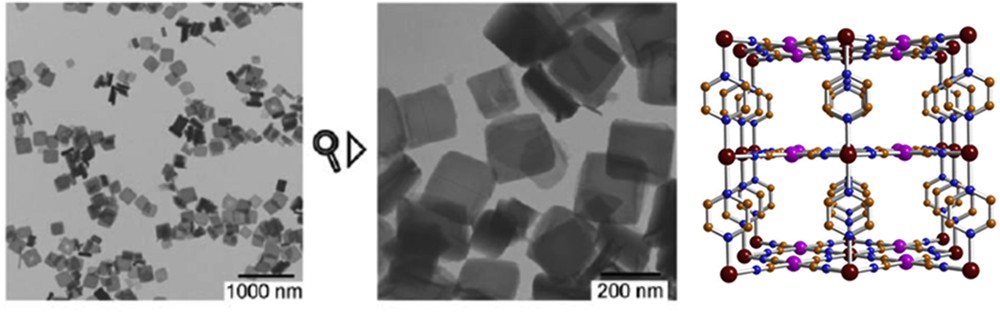

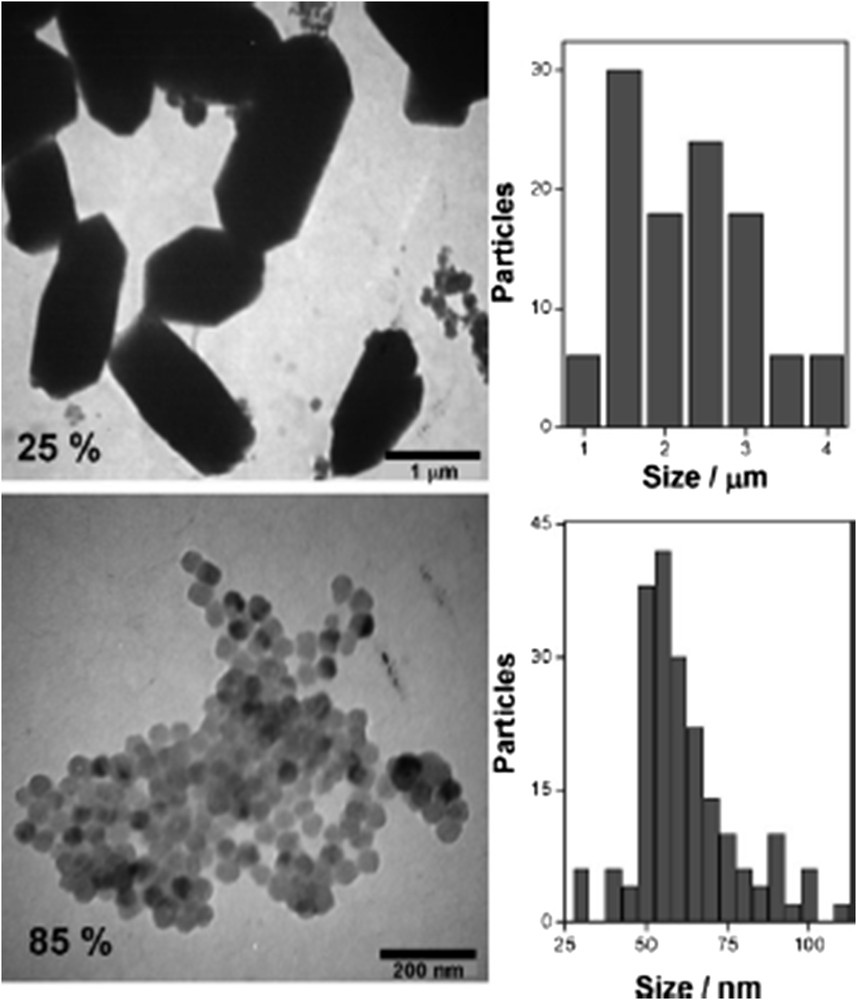

Different synthetic approaches have also been reported for the elaboration of Hofmann-like clathrate 3D network [Fe(L){M(CN)4}] (L = bridging ligand as pyrazine (pz), azopyridine (azpy), etc., M = Pt or Ni) NPs. The water-in-oil microemulsion technique has been used by both Boldog et al. [99] and Volatron et al. [100] to prepare various sized (8–250 nm) nanocrystals of the [Fe(pz){Pt(CN)4}] compound (Fig. 12). In all cases, using a water/AOT/octane ternary system, the control in the size was achieved by modifying the concentration of the precursors and thus the ω factor. The study of the magnetic properties revealed that upon a reduction in the size, particles display SCO behavior, which is different from the bulk. In the anhydrous forms of these nano-objects, the observed modification of the transition temperature, the hysteresis width, the abruptness of the transition, and the residual fractions were related to the size reduction effect (Fig. 13).

TEM images of nanocrystals of the [Fe(pz){Pt(CN)4}] complex and its schematic crystal structure. Adapted from Ref. [99].

Magnetic properties of nanocrystals of [Fe(pz){Pt(CN)4}] of 15 × 15 × 5 (2) and 8 × 8 × 3 (1) nm3 size compared with that of the bulk. Adapted from Ref. [100].

Adapting the microemulsion synthesis, van der Veen et al. [101] obtained 600 × 600 × 30 nm3 [Fe(pz){Pt(CN)4}] nanocrystals and studied the thermal and photoinduced spin state switching on the nanosecond scale for single objects using 4D electron microscopy. In comparison with the measurements on an assembly of particles, a more gradual thermal spin transition with a smaller hysteresis loop has been detected for the isolated particle and the dynamics is significantly faster. Sagar et al. [102] reported a femtosecond time-resolved spectroscopic study of size-dependent dynamics in nanocrystals of the same material. It was observed that smaller NPs (123 or 78 nm cross-section) exhibit SCO with time constants of ∼5–10 ps whereas a ∼20 ps time scale is measured for larger NPs (375 nm cross-section). The authors suggest that the SCO is less efficient in larger NPs owing to their larger size and hence lower residual LS/HS fractions.

The 2D SCO polymers [Fe(3-Fpy)2{M(CN)4}] (M = Ni, Pd, Pt) were also nanostructured in the form of nanocrystals and NPs [45]. Surfactant-free nanocrystals of average length of 400 nm were synthesized from water-in-oil microemulsions, whereas smaller size NPs ranging from 200 to 70 nm were only obtained in PVP-coated polymer. The SCO process is drastically influenced by the dimensions of the crystal/particle. The large nanocrystals exhibit a quasi-complete first-order spin transition centered within the interval 200–225 K, whereas all PVP-coated NPs undergo continuous second-order spin transition at much lower temperatures (ca. 160 K). The nanostructuration of both 2D and 3D Hofmann-like clathrate polymers has provided better insight into the correlation between the maintaining of the cooperativity at reduced size and the dimensionality of the polymer. Despite SCO materials based on the 2D polymers and the 3D one [Fe(pz){Pt(CN)4}] feature cooperative “efficiency” for the bulk material, the 2D polymer NPs (200 nm), undergo incomplete second-order spin transition whereas first-order transition is still observable for the 3D polymer nanocrystals (15 nm). This experimental fact clearly demonstrates, as anticipated, that the 3D polymer enables better cooperativity of the spin transition process.

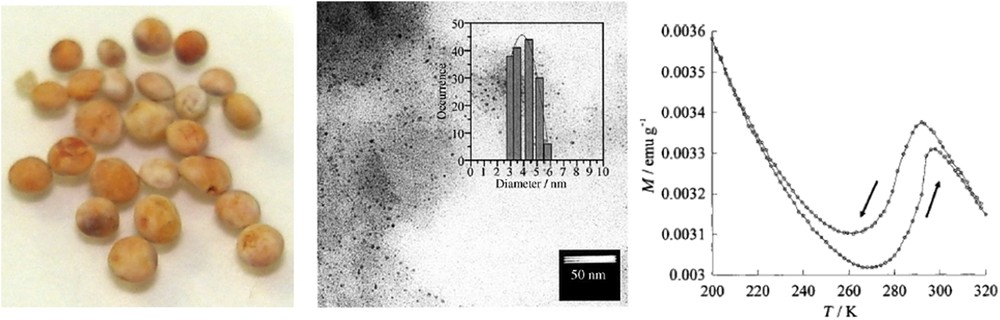

The synthesis of ultrasmall NPs of the SCO CP [Fe(pz){Ni(CN)4}] analogue was also demonstrated by using chitosan biopolymer as matrix [103]. Chitosan is a natural biopolymer obtained by deacetylation of chitin (poly-b-(1,4)-acetylglucosamine) from seafood industry waste (crab and shrimp shells and squid pens) and more rarely from fungi [104]. The procedure was adapted from the multilayer sequential assembly process developed for the preparation of the corresponding thin films [105]. The advantages of this strategy consist of (1) the possibility to covalently anchor the cyanide-bridged metallic network at the reactive functional amino groups of the chitosan; (2) the possibility to afford ultrasmall NPs (less than 10 nm corresponding to the natural size of pores into the chitosan polymer); (3) the water solubility of the chitosan matrix that permits removal of the NPs from the matrix. Thus, the porous chitosan beads allow the reproducible growth of ∼4 nm NPs with a narrow size distribution (Fig. 14). The study of the physical properties of these nanocomposite beads notably by Mössbauer spectrometry revealed that only ca. 1/3 of the FeII ions of the NPs undergo a cooperative thermal spin transition with a hysteresis loop. The decrease in the fraction of iron ions involved in the spin transition in comparison with powder or larger sized NPs may be related to the high percentage (ca. 2/3) of iron ions localized at the surface of the NPs. Indeed, it can be suggested that the different environments around the iron atoms localized at the surface, in comparison with those inside the NPs, can lead to the loss of the SCO properties. Thus, in contrast to that was expected, it seems that even very small particle (3–4 nm) with a few hundreds of SCO metal ions can exhibit high cooperativity. However, if we compare the magnetic properties of the same NPs with comparable size previously obtained by using the reverse micelles method showing more gradual conversion, we can conclude that in the present case the preservation of the cooperativity and the hysteresis loop should be explained by the specific matrix effect generated by the chitosan polymer (see Section 2.3).

(Left) Photograph of the nanocomposite chitosan beads containing [Fe(pz){Ni(CN)4}] NPs. (Middle) TEM images of the NPs within the chitosan beads; the inset shows the size distribution histogram of the NPs. (Right) Temperature dependence of the magnetization measured for the nanocomposite beads at heating and cooling rates of 0.5 K min−1. Adapted from Ref. [103].

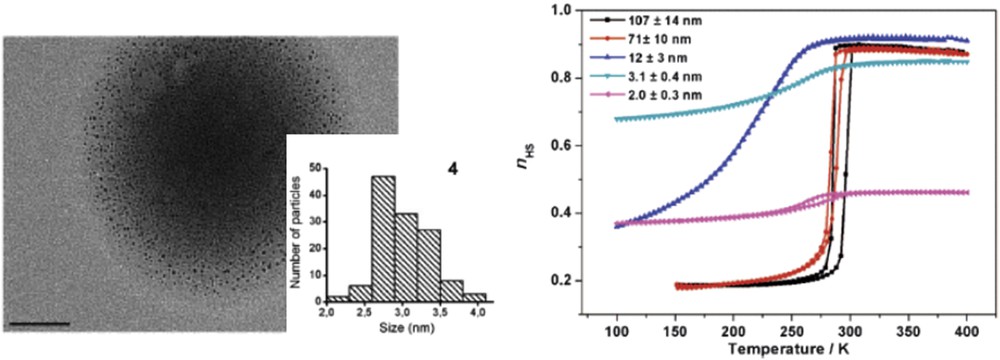

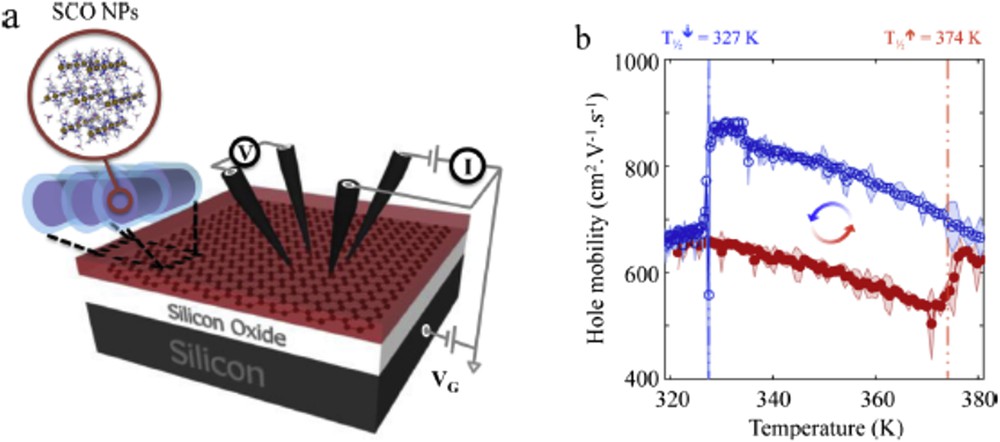

The reverse nanoemulsion technique was also used for the elaboration of different size [Fe(pz){Ni(CN)4}] NPs [106]. With the objective to reach sizes down to 2–3 nm both the preparation of the starting nanoemulsion and the micellar exchange reaction were performed at low temperature. By modifying both the temperature and the concentration of the reactants NPs with sizes from 2 to 110 nm could be obtained. It is interesting to note that a significant change in the color of the powder samples could be observed as a function of the particle size. The darkening of the sample can be explained by the increasing residual LS fraction at room temperature when the size of the NPs decreases. When decreasing the size of the particles from 110 to 12 nm the spin transition shifts to lower temperatures, becomes gradual, and the hysteresis shrinks in agreement with the result reported for the platinate derivative (Fig. 15). On the other hand, a reopening of the hysteresis was observed for smaller (2 nm) particles.