1 Introduction

The gallophosphate cloverite is one of the most interesting large-pore molecular sieves developed during the course of the last decade. It possesses two different pore systems and cavities. The large pores have a diameter of 13.2 Å and are formed by 20 corner-linked (Ga,P)O4 tetrahedra. The narrow pore system consists of eight-ring windows with a diameter of 3.8 Å. At the intersections of the large pores there are supercages with a diameter of 29–30 Å. The accessibility of these cavities is, however, restricted by structural P-OH and Ga-OH groups stretching into the pores [1]. Nevertheless, cloverite was expected to become a promising candidate for application because of its ability to adsorb large molecules within the pores and cavities and to catalyze reactions of larger molecules.

Cloverite was first synthesized by Estermann et al. [1] in 1991. In their paper the authors described the full structure and pointed already to a crucial property of cloverite, i.e. its structural instability after detemplation. This becomes evident when a detemplated cloverite sample is stored at ambient conditions or when ammonia is being allowed to adsorb on the detemplated sample. As a consequence, adsorbed water or ammonia molecules destroy the structure of cloverite within hours. Later, Müller et al. [2] could show that these polar molecules attack the Ga–O bonds of the structure which unavoidably leads to a collapse of the complete structure. A storage of a detemplated cloverite sample as well as a further investigation of the properties of cloverite is consequently difficult due to a rapid change of its structural integrity.

This might be one of the reasons why in the following period only few research groups continued the investigation of cloverite. In most cases the structural properties have been further verified [3,4]; however, nearly no information on a possible application have been reported with the exception of two papers on the formation of methyl-tert-butylether (MTBE) and ethyl-tert-butylether (ETBE) from methanol and ethanol, respectively, and iso-butene on cloverite, published by Richter et al. [5,6].

In recent papers [7–11] the basis of a possible further application has been established. Adachi et al. [7–9] grafted Sn organometallic complexes inside the cloverite pores whereas Zubowa et al. [10,11] showed that liquid crystals could be stored inside the pores without destroying the structure.

The present contribution gives a summary on the conditions under which cloverite can be synthesized and will focus on questions connected with the stability of its structure as well as on a possible application in catalysis despite the structural instability.

2 Experimental

The cloverite samples were synthesized under autogenous pressure from gels having the following composition: 1.0 Ga2O3: 1.0 P2O5: 6.0 Q: 2.2 HF: (0, 1 TiO2)* 200 H2O (Q quinuclidine, *TiO2 used in some cases to study the influence of heteroatoms on the crystallization process of cloverite). Chemicals: Ga2(SO4)3 from Aldrich, H3PO4 (85%, Laborchemie Apolda), quinuclidine (Fluka), HF (48%, Aldrich), tetraethyl orthotitanate. The preparation of the synthesis gel was given elsewhere [12].

The silanes used for modification were chlorotrimethylsilane (CTMS), tri-methylsilane (TMS), and tetraethoxysilane (TEOS); all compounds were obtained from Fluka. Their loading on cloverite has been carried out after detemplation of the samples for about 1 h at 550 °C in a stream of air and in situ evacuation at 400 °C for 4 h at a pressure of 1.3 × 10–3 mbar. The samples were then cooled down to room temperature and the silane chosen was injected on the sample under vacuum.

In some cases cloverite was modified by metal compounds (Table 1) [12]. To obtain a crystalline product, it was necessary to increase the HF content in the gel up to 4.0 mol for Fe- and Ni-cloverite and up to 5.0 mol for Al- and Cu-cloverite. The following chemicals were used for these modifications: tetraethylorthosilicate, tetraethylorthotitanate, Ni(II)- and Fe(III) sulfate, Cu(II) nitrate and Al-iso-propoxide.

Microwave synthesis of Ti-cloverite. Variation of crystallization conditions

| Synthesis conditions | Product | Average crystal size (μm) | Pore volume (cm3 g–1) |

| 1. Variation of time (170 °C, 315 W mw power, 200 H2O) | |||

| 1 h | Cloverite | 1–2 | 0.23 |

| 2 h | Cloverite | 1–4 | 0.25 |

| 5 h | Cloverite | 1 | 0.21 |

| 6 h | Cloverite | 1 | 0.17 |

| 2. Variation of temperature (5 h, 315 W mw power, 200 H2O) | |||

| 130 °C | GaPO4-a | – | |

| 150 °C | Cloverite | 1–2 | 0.26 |

| 170 °C | Cloverite | 1 | 0.21 |

| Stepwise* | Cloverite | 25–30 | 0.27 |

| 3. Variation of mw power (200 H2O, stepwise*) | |||

| 20% | Cloverite | 30–40 | |

| 50% | Cloverite | 25–30 | 0.27 |

| 100% | Cloverite | 25–30 | |

| 4a. Variation of the concentration of water in the gel (315 W mw power, stepwise*) | |||

| 70 H2O | Amorphous | ||

| 120 H2O | GaPO4-a | ||

| 160 H2O | GaPO4-a | ||

| 200 H2O | Cloverite | 25–30 | 0.27 |

| 250 H2O | Cloverite | 25 | 0.27 |

| 270 H2O | Cloverite + x | 18 | 0.21 |

| 300 H2O | Cloverite + x | 10 | |

| 4b. Variation of the concentration of water in the gel (130 W mw power, stepwise*) | |||

| 200 H2O | Cloverite | 30–40 | |

| 320 H2O | Cloverite | 5–10 | |

| 5. Variation of the HF concentration (315 W mw power, 200 H2O) | |||

| 0.8 HF | Amorphous | – | |

| 1.1 HF | Amorphous | – | |

| 1.7 HF | Cloverite | 30 | |

| 2.0 HF | Cloverite | 60 | |

| 2.2 HF | Cloverite | 35 | |

| 3.2 HF | Cloverite | 4 | |

| 4.0 HF | Cloverite | 2 |

The crystallization was carried out in a MDS 200 microwave device (CEM) equipped with a microprocessor allowing the simultaneous measurement of pressure and temperature within the autoclaves. The crystallization temperature was chosen between 120 and 170 °C, the time of crystallization between 1 and 5 h. The microwave power was equal to 315 W at a radiation frequency of 2450 MHz. To remove quinuclidine by the standard procedure the cloverite sample was calcined temperature-programmed in an air stream at a heating rate of 10 K min–1 from room temperature to 550–650 °C and was then isothermally calcined at this final temperature for 1–2 h. Modifications of the standard procedure will be explained in the text.

The products were characterized by XRD (STOE STADI P, Cu Kα radiation), FTIR (Mattson 5000, Unicam) and NMR (Varian UNITY + 300). Adsorption measurements were made with an ASAP 2010 M device (Micromeritics); thermal analysis was carried out on a TGDTA 92 (Setaram) in Ar. SEM images were made on a DSM 982 GEMINI microscope.

The samples are designated as follows: Q-cloverite (Q = quinuclidine) means the template-containing form whereas the cloverite loaded with silanes has the abbreviated Si source in front, e.g. CTMS-cloverite indicates modification by CTMS.

3 Results and discussion

3.1 Crystallization

For their first successful synthesis attempts Estermann et al. [1] have used a synthesis mixture (1.0 Ga2O3: 1.0 P2O5: 6.0 Q: 0.75 HF: 64 H2O) with lower concentrations of HF and H2O than mentioned above. Later, the advantage of using higher concentrations of HF was pointed out by Guth et al. [13]. Usually, the gel was heated in a Teflon-lined stainless steel autoclave at about 120–170 °C for 15–24 h [3,13] in an oven. Applying these conditions crystallization leads to cubic or truncated cubic cloverite crystals [3,4,14].

Microwave radiation was applied by Zubowa and Fricke [12,15–17] as well as by Park and Komarneni [18]. Advantages of microwave radiation are firstly, that the crystallization times for cloverite are much shorter (about one order of magnitude) and secondly, that investigations of the crystallization process can be performed in a time-efficient way.

As an example, the synthesis conditions have been varied in a series of experiments with the aim to determine the influence of gel composition and of synthesis conditions on phase composition, crystal size and pore volume of the synthesis products. Results are given in Table 1.

The following conclusions can be drawn.

- 1. The concentrations of water and HF are important factors influencing the crystallization of cloverite under microwave radiation as already emphasized by Guth et al. [13] for crystallization with conventional oven heating. Within the scope of our experiments a relative molar concentration of 200 H2O/1.0 Ga2O3 and an HF concentration of 2.0/1.0 Ga2O3 are necessary to obtain well crystallized cloverite material.

- 2. Synthesis times exceeding 1 h and the microwave power applied are not important. From the use of microwave radiation for syntheses of other zeolites it is known that in some cases the time necessary to synthesize the zeolite is even much shorter than 1 h. It is obvious, that longer synthesis times have no detrimental influence on the quality of the crystallization product but, also, they do not lead to further improvements.

- 3. Concerning the temperature the situation is not so clear. Undoubtedly, at least a temperature of 150 °C has to be applied. Otherwise, the dense GaPO4-a phase will be formed. On the other hand, a stepwise increase of the crystallization temperature from 120 °C (1 h) to 140 °C (1 h), 160 °C (1 h) and finally to 170 °C (2 h) has always led to much larger crystals. This can neither be the influence of the duration of the synthesis process nor of the high temperature because a separate variation of these parameters did not lead to large crystals. It is rather suggested that the slow approach to the crystallization conditions has a strong influence on the crystallization process itself.

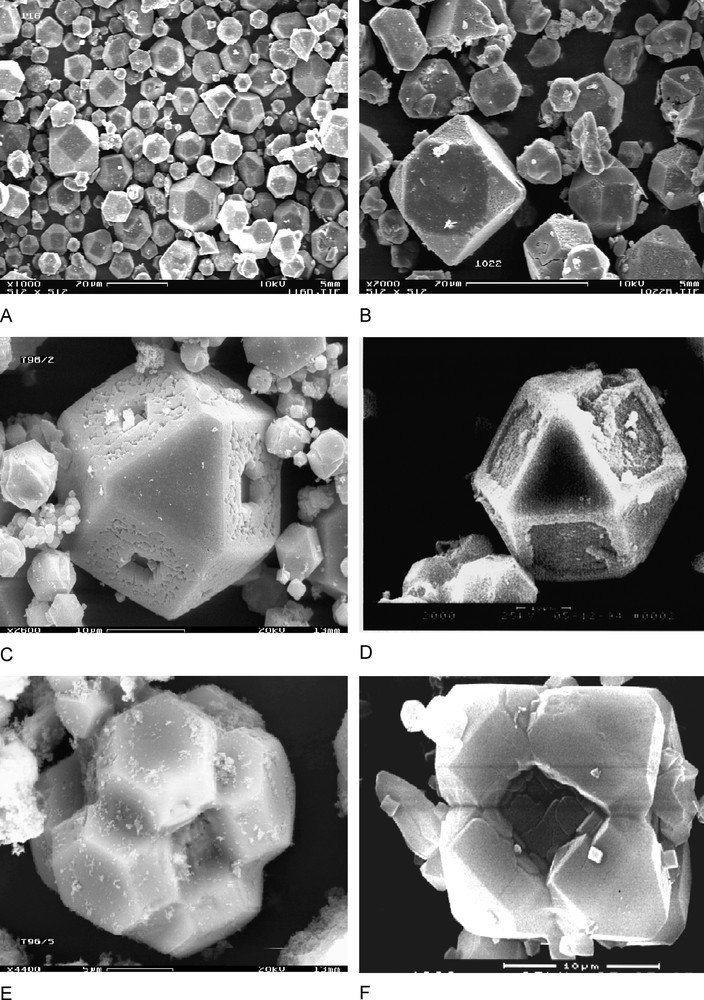

When analyzing the SEM images of the as-synthesized cloverite samples, some other peculiarities appear which might be also discussed in connection to the crystallization process. In most cases the products crystallized in the microwave do not show cubes as obtained by Estermann et al. [1] and Bedard et al. [4] but show truncated cubes or cubo-octahedra (Fig. 1a, b) which, in dependence on the synthesis conditions, may reach a size of 100 μm. Usually, the two different crystal faces consist of squares and hexagonal areas, where the squares have a variable size which leads to hexagonal areas with neighboring edges of different lengths (only in one special case the lengths are identical). Extremely seldom the SEM images show octagonal faces which would correspond to truncated cubes (Fig. 1b).

SEM images of selected cloverite crystals (as-synthesized) synthesized by microwave radiation. a and b: main crystal morphology, c–f were also taken from routinely synthesized cloverite products (maximum concentration of these crystals was some few per cent only). No clear dependence of the formation of these crystal types on the applied synthesis conditions could be found.

One may ask if cubes and octahedra are starting or final points of a crystallization process in cloverite. Because in no case octahedra have been found as crystallization products one may suggest that cubes are the final product of crystallization growth.

There are, however, some other observations which give interesting information on the formation process of large crystals two of which are shown in Fig. 1c, d. It has to be mentioned that these observations have been made in a representative number of cases, i.e. it can be excluded that the selected crystals have to be regarded as a singularity of one special crystallization process.

In the first SEM image the square planes of the crystal all show holes in their center (Fig. 1c). In another crystal shown in Fig. 1d the square plane is nearly completely open like a “window”. The reason for these holes of different size are not quite clear and the experimental basis up to now does not allow to propose a crystallization mechanism. However, if crystals grow and simultaneously change their shape different crystal faces must grow with different rate. It is known from crystal physics that planes that grow faster than others will continuously decrease in size and will be disappeared if the final stage of crystallization is reached. In this connection we have also checked if these holes and “windows” can be the result of “leaching” from the mother liquor after crystallization, i.e. we have stored the final crystallization product for an additional hour in the liquor before opening the autoclave and washing the synthesis product. No increase of the concentration of such crystals could be observed. It could be confirmed, however, that the crystals lost the smoothness of their surface, but without any preference for one of the crystal faces. This ‘face preference’ is, however, one characteristics of the crystals shown in Fig. 1c, d.

Another peculiarity sometimes observed is shown in Fig. 1e, f. Here, the SEM images show crystals which seem to be aggregates of surprisingly high regular shape. If aggregating in the way shown in these images they also form such windows mentioned above. One may speculate on a possible significance of these observations for the interpretation of the crystallization process and whether there is a connection between these observations or not. This would, however, make it necessary to extend these investigations goal-directed.

3.2 Stability of the cloverite structure

In its as-synthesized form (i.e. without any detemplating treatment) the structure of cloverite is quite stable. This has been proven by Bedard et al. [4] who reported a catastrophic break-down of the cloverite framework around 770 °C. This means that cloverite can be regarded as thermally stable at least up to about 700 °C. Simultaneous XRD and IR measurements got Schmidt et al. [19] to regard 600 °C as a critical border-line temperature for the cloverite structure when treating the as-synthesized crystals.

Once being detemplated the cloverite framework has to be handled with care. Already in the early reports it has been mentioned that moisture as well as ammonia have to be regarded as ‘poison’ for the stability of the framework, i.e. already after a storage of the detemplated sample under ambient conditions the framework collapses completely [3,4,19]. It has been suggested by Müller et al. [2,20] that the polar water or ammonia molecules, when entering the narrow pore system, are able to increase the coordination number of the framework gallium atoms from five to six. This leads to the observed instability of the framework which finally results in a complete collapse of the framework. This property would make cloverite unsuitable for application in separation processes and in catalysis.

In a recent paper Girard et al. [21] have theoretically investigated the stability of a great number of existing and hypothetical gallophosphate structures. However, the authors could not apply their model to cloverite due to the fact that the as-synthesized cloverite framework is interrupted by terminal oxygens (P-OH and Ga-OH groups). As a general observation the authors found from their calculations that “all the modified frameworks show very distorted environments around the Ga metal atoms emanating from the removal of oxygen or fluorine atoms from their coordination sphere”. With relation to the cloverite structure this conclusion would support the above mentioned findings of Müller et al. [2] on a particular sensitivity of the Ga coordination and coordination sphere in the case of adsorption of polar molecules.

Some attempts have been made to overcome this structural drawback with respect to a future application of the cloverite molecular sieve. Very early, it has been observed that it is possible to protect the framework from the attack of polar molecules by adsorbing nonpolar molecules. Table 2 gives an overview on a number of adsorbents and their action on framework stability of cloverite.

Influence of the adsorption of various compounds on the framework stability of cloverite

| Sorbate | Stabilitya | References |

| Water | Low | [3] |

| Xylenes | High | [3] |

| n-Hexane | High | [3,19] |

| Decane | High | [19] |

| Ammonia | Low | [14] |

| Pyridine | Medium | [22] |

| Carbon monoxide | High | [22] |

| Nitrogen, liquid | High | [23] |

| Alcohols (MeOH, EtOH, PrOH) | High | [2] |

| Benzene, toluene | High | [2] |

a Classification according to reversible/irreversible changes of the cloverite structure (based on FTIR measurements) after adsorption (mostly at r.t.) and desorption (isothermally or temperature-programmed) of probe molecules.

3.3 Pore filling

Schmidt et al. [19] reported that after adsorption of hexane and decane above 100 °C the storage of the detemplated cloverite samples could be performed successfully over several months.

The effects of only partial detemplation of cloverite on its framework stability have also been studied. It has been found that after destruction of up to 50% of the template (quinuclidine) the stability of the framework structure is maintained [23].

Pore filling with liquid crystal compounds has also been extensively studied with respect to the stability of the cloverite framework as well as of the preservation of the properties of the liquid crystals within the pores and cages of the cloverite structure [10,11]. It could be shown that the cloverite structure as well as the molecular structure of the liquid crystals are maintained after adsorption. Adsorption and desorption of liquid crystals are reversible processes because P-OH and Ga-OH bands at 3665 and 3695 cm–1, respectively, reappear after desorption of the liquid crystals. Evidence has been found for the formation of a new smectic phase of the liquid crystals [11].

3.4 Isomorphous substitution by other metals

Further attempts to stabilize the cloverite framework by isomorphously substitute gallium or phosphorus of the framework by other metals with varying valency (Ni, Cu, Fe, Al, Ti, Si) failed [23]. BET measurements documented a slightly slower loss of surface and pore volume under ambient atmosphere for the metal-modified cloverite variants, however, no systematic influence on the stability compared to the non-substituted version of cloverite could be observed.

3.5 Reactions with silanes

It is known from literature that adsorption or reaction of silanes with oxide surfaces leads to strong modifications of the oxide with respect to hydrophobicity, acidity etc. Important aspects of these reactions have been reviewed by Hair and Tripp [24]. To give an example on the effect of silanation the work of Klemm et al. [25] may be taken where the authors could show that silanation of the surface of a Y-type zeolite distinctly changed acidity and selectivity by reaction of the silanes with the surface hydroxyl groups and by pore blocking. In addition, shape selectivity effects in the disproportionation of ethylbenzene have been observed as well as effects on the deactivation behavior in dependence on the concentration of the adsorbed silanes.

We have investigated if the reaction of silanes with the surface of cloverite could be a suitable tool to protect the framework against moisture. The silanes have been adsorbed on pre-evacuated cloverite samples (at 550 °C) under the conditions described in the experimental part. The concentration of adsorbed silane amounted to about 0.65 ml silane/gcloverite. Fig. 2 shows the XRD pattern of three cloverite samples after modification with different silanes in comparison with an as-synthesized cloverite sample which has not been detemplated.

XRD pattern of a) cloverite, as-synthesized b) TMS-cloverite, c) CTMS-cloverite; d) TEOS-Ti-cloverite. Pattern b–d were taken after 7 days storage of the samples at ambient conditions. Silane concentration = 0.65 ml g–1. The indexing of the reflections were taken from Bedard et al. [4].

In all samples modified by silanes the reflexes of the low angle region (2Θ ≤ 12°) which represent the long-range order of the crystal are present after silanation as well as after 7 days of storage at ambient conditions.

The intensity ratios of some of the peaks (220, 222 and 400 reflections) are different from that of the pure cloverite sample. For TMS-cloverite and CTMS-cloverite the 220 and 400 reflections disappeared after the storage or are of low intensity. For TEOS-cloverite low intensities were found for the 222 and 400 reflections. According to Bedard et al. [4] the variations of these XRD reflection intensities seem to be caused by water molecules adsorbed inside the rpa cages after storage on air.

The short-range order of the structure has already been influenced by the adsorption of the silanes because no reflections are observed at 2Θ ≥ 12. This effect has also been observed after adsorption of liquid crystals into the pore system [10] and points to distortions of the ordering by the adsorbed molecules.

As has been confirmed by FTIR measurements the silanes react with the hydroxyl groups (P-OH and Ga-OH) of the cloverite framework [26]. Stepwise treatment in vacuum up to 400 °C did not reactivate the hydroxyl groups thus confirming that the silanes are strongly bonded to the cloverite surface. Evidence for this conclusion can be also derived from 1H-NMR measurements (Fig. 3). Fig. 3a shows the initial spectrum of the as-synthesized cloverite sample. Five lines at chemical shifts of 2.1, 3.4, 5.3, 6.4, and 8.1 ppm could be observed. Following the only literature data available for comparison [4,27] the lines at 2.1 and 3.4 ppm should be assigned to C–Hx of the quinuclidine cation whereas the peaks at 6.4 and 8.1 (7.6) ppm to P-OH and Ga-OH groups with the broad background belonging to adsorbed water which disappeared after thermal vacuum treatment up to 450 °C [4]. On the basis of these experiments this assignment seems plausible. The peak at 5.3 ppm is not present in the spectra of Bedard and there is no further indication for its origin.

1H-NMR spectra of a cloverite sample, a) as-synthesized, b) after detemplation for 2 h at 550 °C and vacuum treatment at 400 °C for 11 h, c) after adsorption of CTMS on sample b) [26].

On the other hand, after detemplation at 550 °C for 2 h following severe vacuum treatment for 11 h at 400 °C there is only one strong and narrow peak at 3.6 ppm left, together with a broad peak of low intensity at about 0 ppm (Fig. 3b). The peak at 3.6 ppm disappeared completely after CTMS has been adsorbed on the sample (Fig. 3c). Simultaneously a strong peak at 0 ppm appeared assigned to adsorbed CTMS. The peak is asymmetric and superimposed by a broad background chemical shift which is extended up to 15–20 ppm and assigned to partial rehydration of the surface. The assignment of the peak at 3.6 ppm (Fig. 3b) is not quite clear. On the basis of its disappearance after adsorption of CTMS we have, however, concluded that it has to be assigned to P-OH/GaOH groups [26]. Nevertheless, there are still some doubts because there is evidence from IR measurements that also these groups loose considerable intensity if cloverite is vacuum treated at higher temperatures [2,4]. Bedard suggested that there appears some kind of partial fragmentation of double four rings in the framework of cloverite which then leads to the formation of additional terminal hydroxyl groups [4]. It seems reasonable to assume that also these OH groups would react with CTMS as may be concluded from our 1H-NMR spectra.

So far, however, the assignment of the 3.6 ppm peak observed after severe thermal treatment has to be verified or rejected by forthcoming studies.

In summary, with respect to a maintenance of the framework structure of detemplated cloverite samples several methods have been applied which, more or less, all are based on a ‘refilling’ of the pore systems with compounds which are able to prevent strong polar molecules to enter the pores and to coordinate in a destructive way to gallium. The attempts to isomorphously substitute Ga3+ atoms by other metals has been successful to a certain degree and has resulted in new or modified properties of this materials [12,14,28,29], however, in terms of stabilization of the framework structure there was no distinct influence.

3.6 Application of cloverite

With respect to “molecular sieving” and catalysis it is essentially to know the sorption properties of a catalyst. Already in one of the first reports on cloverite Merrouche et al. [3] have determined the adsorption capacity at 25 °C and p/po = 0.5 of n-hexane, p-xylene, m-xylene, mesitylene and tri-iso propylbenzene to reach 15.8, 13.1 14.3, 15.3, and 5.3 wt.%, respectively. These studies have been continued by other authors to benzene, toluene, iso-octane, pyridine and alcohols [2,7].

Adachi et al. [7–9] in a number of papers, have reported on the modification of the cloverite surface by adsorption of organometallic complexes. In near coincidence with studies by our group on the adsorption of silanes ([26], this paper) one aim of their studies was to modify the pore entrances by reaction of the hydroxyl groups with metallocomplexes (grafting) to tune the accessibility of the pore systems. When using tetraethyltin they could show that SnEt4 reacts with the hydroxyl groups of cloverite [7]. Further extended studies which included also the grafting of other tin complexes (–SnR3, R = methyl, n-butyl, cyclohexyl) have shown that the adsorption properties of the modified cloverite samples, i.e. adsorption capacities as well as rates of adsorption, with respect to n-hexane, benzene and iso-octane can be strongly influenced by the kind of anchored complex and by its concentration [7–9]. No stabilization effect of the cloverite framework could be observed after anchoring the tin complexes on the surface.

Only very few studies have been undertaken to evaluate catalytic properties of cloverite. A first information was published by Patarin et al. [14] who studied the cracking of n-heptane at 350 °C. Although no further details on the sample pre-treatment and the test conditions were given, fast deactivation was reported due to severe coking.

The only detailed investigation on catalytic properties of cloverite has been published by Richter et al. [5,6,17] for the etherification of isobutene with methanol and ethanol to MTBE and ETBE, respectively. In these investigations different kinds of pre-treatment of the cloverite sample have been studied in detail. It could be shown that conversion levels as high as about 40% could be reached for methanol as well as for isobutene at a reaction temperature of 100 °C with a MTBE selectivity of more than 80% [5]. At 90 °C the conversion degree of methanol and isobutene decreased slightly to 38% whereas the MTBE selectivity reached 98%. The MTBE yield of 37% reached by cloverite is remarkably high, but does not meet the higher values of about 50% of the commercial Amberlyst-15 catalysts or of zeolite beta [30,31]. However, compared to other zeolite types (HY, ZSM-5, ZSM-12 [32], mordenite, omega) cloverite shows a distinctly higher MTBE yield.

Although water is formed during the reaction no deactivation of cloverite has been observed after more than 6 h reaction; further on, 48 h storage under nitrogen atmosphere preserved the catalytic properties without any loss in conversion or MTBE selectivity. However, it became obvious that these catalytic results could only be obtained if the cloverite sample had been detemplated in situ within the catalytic reactor. During this experiments an oxidative pretreatment at 550 °C has been found to be indispensible. Applying cloverite samples which have been detemplated ex situ and then quickly transferred to the catalytic reactors suffer already a methanol conversion loss from 40% to 25%.

Using ethanol for the etherification comparable high ETBE selectivities could be obtained, however the conversion degree of ethanol and isobutene did not exceed 20% due to thermodynamic reasons [6].

Both reactions are governed by the acidity of the catalyst. It has been already mentioned in literature [2,20,22,33] that the hydroxyl groups in cloverite (P-OH and Ga-OH) exhibit strong or at least medium Brønstedt acidity. This would explain the catalytic properties of cloverite in the etherification reaction. It should, however, be emphasized that also F– ions which are still present in the detemplated cloverite molecule [17] may contribute to the overall acidity of cloverite. There are few experiments only to contribute to an elucidation of these questions.

19F-NMR measurements show a line at a chemical shift at 69 ppm that has been used to compare the F– concentration of the cloverite sample in the as-synthesized form as well as after use in the MTBE reaction. The result shows that about 20% of the original F– concentration is still present after in situ detemplation and MTBE reaction. By means of a fluoride sensitive electrode this relative value could be quantified to about 0.32 wt.% which is about 1 F– ion per 10 unit cells of cloverite.

A Ti-cloverite catalyst showed a conversion degree of isobutene of only 25% (compared to pure cloverite); the relative F– concentration reached 40% under the same conditions. Up to now, it has not been investigated further if titanium, which is in tetrahedral framework coordination or as clusters [17], acts as catalytic active center in cloverite which would have a direct influence on the catalytic reaction. In addition, it is also unknown how other parameters (e.g. temperature, duration and atmosphere of the in situ detemplating process) influence the catalytic performance of catalysts having the cloverite structure.

An amorphous gallophosphate sample of the same chemical composition did not reach such high activity level as pure cloverite or Ti-cloverite. An in situ or post-modification with HF cannot decide the question on a possible contribution of fluoride ions to the catalytic activity of cloverite because it seems doubtful whether the state of fluoride ions in the framework is the same under both conditions, i.e. in the presence and absence of quinuclidine cations (for which F– act as counter ions).

In summary, it is obvious that F– ions are still present in all active cloverite samples after detemplation and during the catalytic reaction but there is still no clear evidence that it is the cloverite structure alone that determines the acidity and catalytic performance of the cloverite catalysts. A certain contribution of fluoride ions to acidity as well as to activity in the formation of MTBE and ETBE has to be considered.

4 Conclusions

Crystallization of the molecular sieve cloverite does not bear any extreme difficulties because the crystallization field is broad. Concerning gel composition and crystallization parameters those conditions can be chosen which allow optimal products with respect to the aim of investigation. In particular, by applying microwave radiation a great number of parameters has been varied showing the borders of synthesis with respect to obtain highly crystalline cloverite material as well as the desired crystal sizes.

Many attempts have been undertaken to stabilize the framework structure. As a conclusion from these results the salient feature seems to be very clear. Whereas the as-synthesized structure is stable at least up to about 600–700 °C the template-free material undergoes fast destructuring under ambient conditions due to coordinative distortions on the Ga atoms by water vapor. No methods are known up to now to directly stabilize the structure itself. Nevertheless, the pore system can be prevented by filling with nonpolar gases or by partial or full blocking by silanes or other complexes. The advantage is that these measures stabilize the framework structure which, on the other hand, includes the disadvantage that the accessibility of molecules which should be converted in a catalytic reaction to the framework is hindered. One can draw the very clear conclusion that if storage of cloverite material is necessary it should be preferentially done in the as-synthesized form.

Compared to other molecular sieve structures there are only very few investigations which can provide information on an application of cloverite material. Modification of the external as well as internal surface of cloverite shows that the adsorption properties, i.e. also the ability to separate molecules from a mixture, can be strongly influenced by anchoring organometallic Sn-complexes or silanes on the surface.

The only available catalytic investigations in the etherification of methanol and ethanol to MTBE and ETBE, respectively, show very interesting properties of cloverite as a catalyst. It seems, however, presently doubtful if the structural instability in the presence of polar molecules will give these molecular sieve a chance to be further investigated and applied.

Acknowledgements

Financial support of the Deutsche Forschungsgemeinschaft (project Fr 992/12-1) is gratefully acknowledged as well as contributions and technical assistance of Dr. D. Müller, Dr. L. Wilde, R. Eckelt and M. Buddrus.