1 Introduction

In recent years, room temperature ionic liquids (RTILs) have attracted much interest as relatively clean and promising catalysts and alternative solvents which possess important attributes such as broad solvating ability, wide liquidus temperature, non-measurable vapor pressure, high catalytic activity, excellent thermal and chemical stability, potential recoverability, design possibilities and ease of the separation of the products from the reaction mixture [1]. In addition, ionic liquids as reaction media, offer better reaction selectivity, higher reaction yields and reusability. In the recent decade, these compounds have found an increasing number of applications in catalysis [2–4], metal extraction [5,6], cellulose dissolution [7,8], energetic materials [9–11], and active pharmaceutical ingredients (APIs) [12]. Furthermore, their excellent thermal and chemical stability, as well as their ease of recycling, make ILs very attractive for industrial applications [13].

Indium (III) species have been used as Lewis acid catalysts in a variety of organic reactions [14]. The advantage of indium (III) chloride compared with aluminium chloride is its hydrolytic stability and reduced oxophilicity. By reaction of indium (III) chloride with an organic halide salt such as [C4mim][Cl], ionic liquids can be formed with good solvating ability and negligible vapor pressure, as well as liquid being both inherently Lewis-acidic and water stable in contrast to the analogues chloroaluminate systems [15].

The range of both microwave (MW) and ultrasonic (US) applications contribute to developing green chemistry, particularly towards developing environment-friendly synthetic procedures. MW-and US-assisted reactions have been successfully carried out in the ionic liquids media, revealing a host of interesting synergic effects [16–18]. Ionic liquids interact efficiently with microwaves through the ionic conduction mechanism and are rapidly heated at rates easily exceeding 10 °C/s without any significant pressure build-up. In fact, the ionic nature of these organic salts facilitates their use in microwave-assisted organic synthesis and makes them highly suitable media for energy transfer to the reaction mixture under microwave irradiation conditions [16]. Hoffmann et al. reported that ionic liquids could efficiently absorb microwave energy by which the reaction rates could be accelerated [19].

In general, US has chemical and mechanical effects. The chemical effects of ultrasound do not derive from a direct coupling of the acoustic field with chemical species on a molecular level. Instead, sonochemistry and sonoluminescence derive principally from acoustic cavitation: the formation, growth and implosive collapse of bubbles in liquids irradiated with high-intensity ultrasound. Bubble collapse during cavitation serves as an effective means of concentrating the diffuse energy of sound: compression of a gas generates heat. When the compression of bubbles occurs during cavitation, heating is more rapid than thermal transport, creating a short-lived localized hot spot. There is a nearly universal consensus that this hot spot is the source of homogeneous sonochemistry [20,21].

Selective introduction and removal or direct conversion of protective groups to the next functional groups is often a necessary process in multi-step synthesis of complex natural products; hence, there is always a demand for selective reagents. Methoxymethylation and ethoxymethylation are the most widely used for the protection of hydroxyl groups of alcohols and phenols [22]. Due to the remarkable stability of methoxymethyl and ethoxymethyl ethers toward a variety of reaction conditions such as strongly basic media, oxidative conditions, reduction with metal hydride, alkylating and acylating reagents, alkoxymethylation is one of the methods of choice for protection of hydroxyl groups in a multi-step organic synthesis [23].

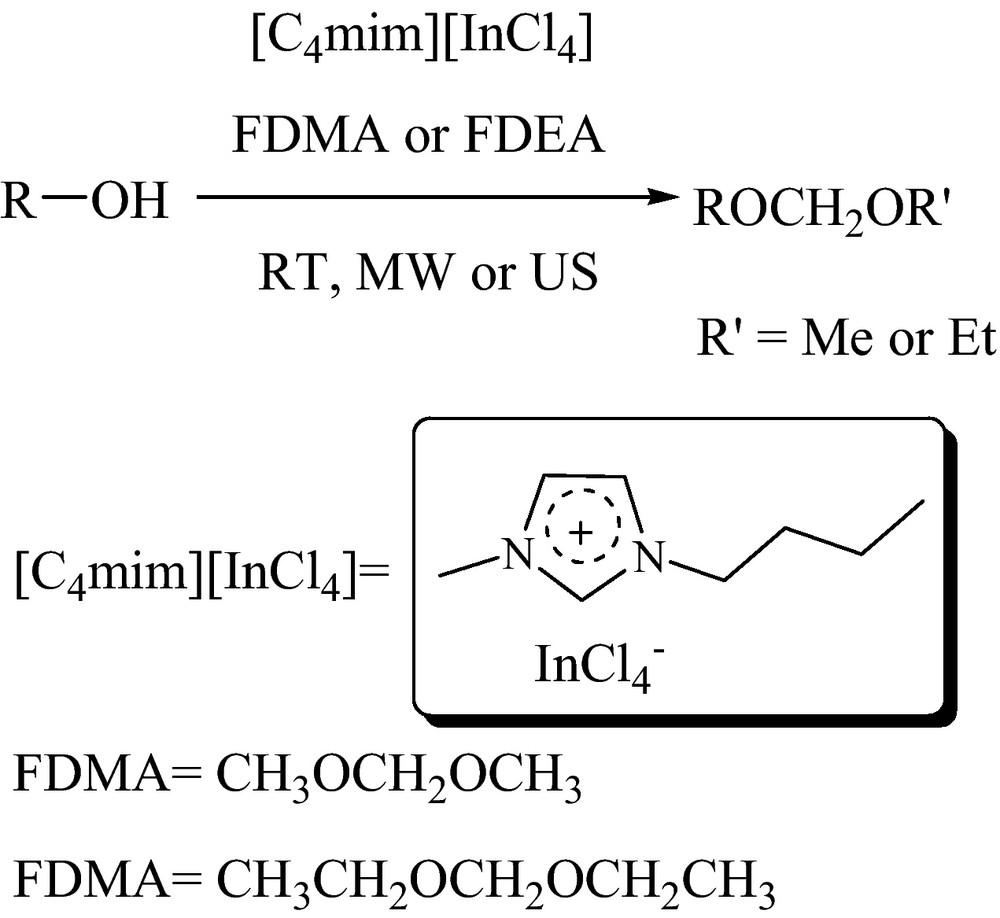

The importance of ionic liquids as novel catalysts and media and also unique catalytic features of indium chloride as a good Lewis acid encouraged us to explore the ability of 1-butyl-3-methylimidazolium tetrachloroindate, [C4mim][InCl4] ionic liquid [24–26] as a highly efficient catalyst-medium for the protection of hydroxyl groups and also direct conversion of methoxymethyl (MOM) and ethoxymethyl (EOM) ethers to other hydroxyl-protecting groups such as acetates and trimethylsilyl (TMS) ethers under different reaction conditions. In continuation to our previous works about the green and new synthetic methodologies [27–31], herein, we report a mild and efficient method for the methoxymethylation and ethoxymethylation of alcohols (Scheme 1) and also direct transformation of them to the corresponding acetates and TMS-ethers (Scheme 2) using [C4mim][InCl4] as a catalyst and medium.

2 Experimental

All materials were purchased from Merck and Sigma-Aldrich chemical companies and were used without further purification. All products are known compounds and were identified by comparison of their spectral and physical data with those of authentic samples [32–36]. All the reactions were monitored by TLC and all yields refer to the isolated products. 1H NMR spectra were recorded on a Bruker-AC500P at 500 MHz. IR spectra were obtained by IR-435 Shimadzu spectrophotometer using KBr or sodium chloride pellets. The microwave system were used for these experiments includes the following items: Micro-SYNTH labstation, complete with glass door, dual magnetron system with pyramid-shaped diffuser, 1000 W delivered power, exhaust system, magnetic stirrer, “quality pressure” sensor for flammable organic solvents, ATCFO fiber optic system for automatic temperature. During experiments, power, temperature, time and pressure monitored and controlled with the “easyCONTROL” software. Temperature was monitored with the aid of ATC-FO sensor TS3517 inserted directly into the corresponding reactions container. The alkoxymethylation reactions under MW irradiation were carried out at 80–90 °C with 100 W applied power in a sealed PTFE vessel.

The ultrasonic device was an UP 400 S instrument from Dr. Hielscher GmbH. A S3 immersion horn emitting 24 kHz ultrasonic at intensity levels tunable up to maximum sonic power density of 460 Wcm−2 was used. Sonication carried out at 100% (maximum amplitude 210 μm). A 3 mm long sonotrode (maximum immerse depth of 90 mm) was immersed directly into the reaction mixture.

2.1 Preparation of the [C4mim][InCl4]

[C4mim][InCl4] was synthesized according to the procedures under thermal conditions [24] and microwave irradiation [25]. In a typical method, InCl3 (0.66 g, 3 mmol) was added to 1-butyl-3-methylimidazolium chloride (0.52 g, 3 mmol) and mixed at 40 °C for 1.5 h or 600 W under microwave irradiation for 15 s. Then a colorless liquid was obtained in nearly quantitative yield.

2.2 General procedure for the preparation of MOM-and EOM-ethers at room temperature, under ultrasonic or microwave irradiation

To a solution of alcohol (1 mmol) in FDEA or FDMA (5 mmol), [C4mim][InCl4] (1.0 mL(was added and stirred at room temperature or exposed to ultrasonic or microwave irradiations for the appropriate time (Table 1). After completion of the reactions (monitored by TLC, eluent: n-hexane/ethyl acetate, 4:1), the excess FDMA or FDEA were removed under reduced pressure. H2O (10 mL) was added and the mixture was extracted with Et2O (2 × 10 mL). The organic phase was dried over anhydrous Na2SO4 and rotary evaporation afforded a residue, which was then passed through a short pad of silica gel (eluent: n-hexane/ethyl acetate, 4:1) to give the pure MOM-and EOM-ethers.

Preparation of MOM- and EOM-ethers from alcohols in [C4mim][InCl4] at room temperature, under ultrasonic and microwave irradiationsa.

| Entry | Alcohol | EOM-ether | MOM-ether | ||||

| Time, min (Yield, %)b | Time min (Yield %)b | ||||||

| RT | US | MW | RT | US | MW | ||

| 1 | 120 (88) | 45 (90) | 2 (94) | 120 (90) | 45 (91) | 2 (95) | |

| 2 | 90 (90) | 35 (96) | 1.5 (96) | 120 (92) | 35 (93) | 1.5 (95) | |

| 3 | 90 (87) | 40 (89) | 2.5 (90) | 90 (89) | 35 (90) | 2 (93) | |

| 4 | 120 (86) | 60 (90) | 2.5 (93) | 120 (85) | 60 (88) | 2.5 (94) | |

| 5 | 90 (91) | 30 (91) | 2 (93) | 90 (90) | 30 (91) | 2 (95) | |

| 6 | 90 (87) | 35 (89) | 2.5 (92) | 90 (88) | 35 (90) | 2 (92) | |

| 7 | 60 (91) | 25 (91) | 1.5 (93) | 60 (91) | 20 (92) | 1.5 (95) | |

| 8 | 60 (94) | 20 (93) | 1.5 (97) | 60 (94) | 20 (93) | 1.5 (97) | |

| 9 | 60 (90) | 30 (91) | 1.5 (91) | 60 (91) | 30 (91) | 1.5 (93) | |

| 10 | 60 (91) | 25 (94) | 1.5 (96) | 60 (93) | 25 (93) | 1.5 (97) | |

| 11 | 60 (92) | 25 (93) | 1.5 (94) | 60 (92) | 25 (95) | 1.5 (95) | |

| 12 | 60 (90) | 30 (91) | 2 (94) | 60 (89) | 30 (92) | 2 (92) | |

| 13 | 135 (87) | 45 (86) | 3.5 (89) | 120 (85) | 45 (87) | 3.5 (90) | |

| 14 | 330 (80) | 120 (83) | 9 (84) | 300 (82) | 120 (81) | 8.5 (83) | |

| 15 | 195 (87) | 60 (87) | 4.5 (89) | 195 (93) | 60 (90) | 5 (90) | |

| 16 | 210 (85) | 75 (88) | 5 (89) | 210 (84) | 75 (85) | 5 (88) | |

| 17 | 60 (92) | 25 (94) | 1.5 (97) | 60 (92) | 25 (94) | 1.5 (97) | |

| 18 | 90 (90) | 30 (92) | 3 (92) | 90 (93) | 30 (94) | 3 (96) | |

| 19 | 90 (91) | 35 (90) | 3 (92) | 90 (93) | 30 (96) | 3 (96) | |

| 20 | 270 (81) | 90 (84) | 8 (84) | 270 (85) | 90 (85) | 7.5 (87) | |

| 21 | 195 (88) | 60 (87) | 6 (90) | 195 (89) | 60 (89) | 6 (91) | |

| 22 | 240 (82) | 80 (83) | 7 (87) | 240 (84) | 75 (85) | 7 (88) |

a Reaction conditions: alcohol (1 mmol), FDMA or FEDA (5 mmol), [C4mim][InCl4] (1 mL).

b Isolated yield.

2.3 General procedure for the interconversion of EOM-and MOM-ethers to acetates and TMS-ethers under thermal conditions, under ultrasonic and MW irradiations

A mixture of MOM-or EOM-ether (1 mmol), acetic anhydride or hexamethyldisilazane (HMDS) (5 mmol) was added to [C4mim][InCl4] (1 ml) and stirred at 80 °C or exposed to US or MW irradiations (all reactions were carried out at 145–150 °C with 160 W applied power). After completion of the reaction (monitored by TLC, eluent: n-hexane/ethyl acetate, 4:1), the excess of Ac2O or HMDS were removed under reduced pressure and H2O (10 mL) was added. The mixture was extracted with Et2O (2 × 10 mL). The organic phase was dried over anhydrous Na2SO4 and rotary evaporation afforded the residue, which was then passed through a short pad of neutral alumina (eluent: n-hexane/ethyl acetate, 4:1) to give the pure acetates and TMS-ethers.

2.4 Recycling of the [C4mim][InCl4]

The reusability of [C4mim][InCl4] was investigated in the multiple sequential methoxymethylation of benzyl alcohol with FDMA. At the end of the reaction, the excess FDMA was evaporated and H2O (10 mL) was added. Then, the product was extracted with diethyl ether (2 × 10 mL). The aqueous phase containing IL was dried in vacuo for further use.

2.5 Spectroscopic data for selected products

Benzyl acetate (Table 2, entry 1).

Interconversion of MOM- and EOM-ethers to the corresponding acetates in [C4mim][InCl4] under thermal conditions, ultrasonic and microwave irradiationsa.

| Entry | Alkoxymethyl ether | Transformation of EOM-ether (R = CH2OEt) | Transformation of MOM-ether (R = CH2OMe) | ||||

| Time, min (Yield, % b) | Time, min (Yield, % b) | ||||||

| Heat | US | MW | Heat | US | MW | ||

| 1 | 180 (85) | 60 (88) | 3.5 (91) | 180 (87) | 60 (90) | 3.5 (92) | |

| 2 | 120 (91) | 45 (91) | 2.5 (92) | 120 (89) | 45 (91) | 2.5 (94) | |

| 3 | 180 (86) | 50 (87) | 3 (92) | 180 (84) | 50 (88) | 3 (91) | |

| 4 | 195 (85) | 60 (89) | 3 (92) | 195 (86) | 60 (87) | 3 (93) | |

| 5 | 120 (89) | 45 (90) | 3 (93) | 120 (87) | 45 (90) | 3 (92) | |

| 6 | 165 (86) | 75 (88) | 3.5 (92) | 150 (87) | 75 (89) | 3.5 (93) | |

| 7 | 90 (89) | 35 (90) | 2 (91) | 90 (87) | 35 (89) | 2 (90) | |

| 8 | 90 (87) | 35 (89) | 2 (93) | 90 (88) | 35 (88) | 2 (95) | |

| 9 | 90 (86) | 45 (87) | 2.5 (90) | 90 (87) | 45 (87) | 2.5 (92) | |

| 10 | 90 (89) | 35 (92) | 2 (94) | 90 (88) | 35 (92) | 2 (96) | |

| 11 | 90 (85) | 35 (88) | 2 (92) | 90 (86) | 35 (88) | 2 (94) | |

| 12 | 90 (87) | 45 (88) | 2.5 (93) | 90 (88) | 45 (90) | 2.5 (93) | |

| 13 | 195 (85) | 75 (86) | 4 (89) | 195 (84) | 75 (84) | 4 (90) | |

| 14 | 480 (73) | 180 (75) | 14 (80) | 480 (72) | 175 (77) | 14 (79) | |

| 15 | 240 (83) | 105 (84) | 7.5 (86) | 240 (85) | 105 (84) | 7.5 (86) | |

| 16 | 315 (81) | 120 (83) | 9.5 (85) | 300 (83) | 120 (82) | 9 (84) | |

| 17 | 100 (92) | 35 (94) | 2 (95) | 100 (92) | 35 (95) | 2 (97) | |

| 18 | 120 (88) | 45 (91) | 3.5 (93) | 120 (89) | 45 (89) | 3.5 (93) | |

| 19 | 120 (86) | 45 (86) | 4 (89) | 120 (84) | 45 (86) | 3.5 (88) | |

| 20 | 345 (80) | 135 (81) | 10.5 (84) | 330 (81) | 120 (83) | 11 (87) | |

| 21 | 220 (82) | 90 (84) | 6.5 (90) | 220 (83) | 90 (85) | 6.5 (90) | |

| 22 | 315 (82) | 120 (83) | 8.5 (87) | 315 (84) | 120 (85) | 8 (88) |

a Reaction conditions: Alkoxymethyl ether (1 mmol), Ac2O (5 mmol), [C4mim][InCl4] (1 mL).

b Isolated yield.

IR (KBr): ν (cm−1) 3034, 2955, 1741, 1498, 1456, 1381, 1364, 1229, 1082, 1026, 966, 839, 750, 698, 613, 579, 501; 1H-NMR (500 MHz, CDCl3): δ (ppm) 2.11 (s, 3H, COCH3), 5.13 (s, 2H, OCH2), 7.34–7.38 (m, 5H, Ar).

2-Acetoxybenzyl acetate (Table 2, entry 3). Oil, IR (KBr): ν (cm−1) 2941, 2291, 2252, 1757, 1445, 1375, 1244, 1041, 918, 750, 698; 1H-NMR (500 MHz, CDCl3): δ (ppm) 2.05 (s, 3H, CH2OCOCH3), 2.31 (s, 3H, OCOCH3), 5.08 (s, 2H, CH2OCOCH3), 7.08–7.44 (m, 4H, Ar).

4-Acetoxy-3-methoxybenzyl acetate (Table 2, entry 4). Oil; IR (KBr): ν (cm−1) 2999, 2943, 2850, 2291, 2252, 1738, 1723, 1446, 1377, 1246, 1041, 918, 844, 750, 698; 1H-NMR (500 MHz, CDCl3): δ (ppm) 2.12 (s, 3H, CH2OCOCH3), 2.35 (s, 3H, OCOCH3), 3.78 (s, 3H, OCH3), 5.12 (s, 2H, CH2OCOCH3), 6.99–7.07 (m, 3H, Ar).

2,4-Dichlorobenzyl acetate (Table 2, entry 10). Oil, IR (KBr): ν (cm−1) 3001, 2943, 2848, 2291, 2252, 1743, 1591, 1562, 1446, 1375, 1226, 1105, 1057, 1105, 1056, 918, 842, 816, 744. 1H-NMR (500 MHz, CDCl3): δ (ppm) 2.16 (s, 3H, COCH3), 5.19 (s, 2H, CH2O), 7.27–7.47 (m, 3H, Ar).

4-Nitrobenzyl acetate (Table 2, entry 14). Oil, IR (KBr): ν (cm−1) 2941, 2849, 2291, 2252, 1743, 1533, 1442, 1354, 1228, 1097, 1039, 918, 812, 734, 690, 605; 1H-NMR (500 MHz, CDCl3): δ (ppm) 2.16 (s, 3H, COCH3), 5.20 (s, 2H, CH2O), 7.40–8.40 (m, 4H, Ar).

Benzyloxytrimethylsilanes (Table 3, entry 1). B.p.: 186–190 °C; IR (KBr): ν (cm−1) 3063, 3030, 2966, 1711, 1495, 1452, 1227, 1202, 1068, 1028, 916, 812, 758, 694, 605, 547; 1H-NMR (500 MHz, CDCl3): δ (ppm) 0.16 (s, 9H, OSi(CH3)3), 4.70 (s, 2H, CH2OSi(CH3)3), 7.24–7.33 (m, 5H, Ar).

Interconversion of MOM- and EOM-ethers to the corresponding TMS-ethers in [C4mim][InCl4] under thermal conditions, ultrasonic and microwave irradiationsa.

| Entry | Alkoxymethyl ether | Transformation of EOM-ether (R = CH2OEt) | Transformation of MOM-ether (R = CH2OMe) | ||||

| Time, min (Yield, %b) | Time, min (Yield, %b) | ||||||

| Heat | US | MW | Heat | US | MW | ||

| 1 | 195 (83) | 75 (85) | 4 (90) | 195 (84) | 75 (88) | 4 (94) | |

| 2 | 150 (86) | 60 (87) | 3.5 (90) | 150 (89) | 60 (91) | 3.5 (94) | |

| 3 | 180 (85) | 60 (89) | 3 (92) | 180 (83) | 60 (85) | 3 (92) | |

| 4 | 195 (88) | 75 (87) | 3.5 (91) | 195 (87) | 75 (84) | 3.5 (90) | |

| 5 | 120 (86) | 60 (88) | 3.5 (90) | 120 (87) | 60 (88) | 3.5 (88) | |

| 6 | 165 (85) | 75 (84) | 4 (89) | 165 (84) | 75 (86) | 4 (88) | |

| 7 | 90 (85) | 45 (87) | 4.5 (90) | 90 (87) | 45 (89) | 4.5 (91) | |

| 8 | 90 (84) | 35 (85) | 3 (90) | 90 (83) | 35 (88) | 3 (94) | |

| 9 | 90 (83) | 45 (85) | 3.5 (90) | 90 (84) | 45 (88) | 3.5 (92) | |

| 10 | 90 (85) | 35 (88) | 3 (91) | 90 (83) | 35 (86) | 3 (93) | |

| 11 | 90 (85) | 35 (87) | 3 (90) | 90 (86) | 35 (89) | 3 (93) | |

| 12 | 90 (82) | 45 (86) | 3.5 (91) | 90 (86) | 45 (85) | 3.5 (91) | |

| 13 | 210 (83) | 90 (87) | 5 (89) | 210 (85) | 90 (88) | 4.5 (90) | |

| 14 | 480 (71) | 180 (73) | 16 (78) | 480 (74) | 180 (75) | 16 (77) | |

| 15 | 270 (81) | 120 (82) | 8.5 (86) | 270 (82) | 120 (84) | 8.5 (86) | |

| 16 | 330 (83) | 150 (82) | 11 (86) | 330 (81) | 150 (83) | 11 (86) | |

| 17 | 130 (87) | 45 (89) | 3 (93) | 130 (91) | 45 (91) | 3 (93) | |

| 18 | 150 (86) | 60 (87) | 3.5 (90) | 150 (89) | 60 (91) | 5 (92) | |

| 19 | 150 (85) | 60 (83) | 5 (87) | 150 (86) | 45 (85) | 5 (86) | |

| 20 | 360 (75) | 150 (80) | 13 (81) | 360 (77) | 135 (80) | 13 (81) | |

| 21 | 330 (82) | 150 (84) | 11 (88) | 330 (83) | 150 (83) | 11 (89) | |

| 22 | 330 (82) | 135 (84) | 10 (87) | 330 (80) | 120 (81) | 10 (87) |

a Reaction conditons: Alkoxymethyl ether (1 mmol), HMDS (5 mmol), [C4mim][InCl4] (1 mL).

b Isolated yield.

(2-Methoxy-4-((trimethylsilyloxy)methyl)phenoxy)trimethylsilane (Table 3, entry 4). Oil, IR (KBr): ν (cm−1) 3431, 2956, 2900, 1701, 1637, 1604, 1514, 1463, 1419, 1375, 1280, 1157, 1122, 1037, 904, 850, 754, 688, 634, 557. 1H-NMR (500 MHz, CDCl3): δ (ppm) 0.16 (s, 9H, CH2OSi(CH3)3), 0.24 (s, 9H, OSi(CH3)3), 3.83 (s, 3H, OCH3), 4.63 (s, 2H, CH2Si(CH3)3), 6.77–6.88 (m, 3H, Ar); 13C-NMR (75 MHz, CDCl3): δ (ppm) 55.38, 64.72, 77.40, 109.99, 111.08, 119.43, 120.25, 134.98, 143.84, 150.87.

(2,4-Dichlorobenzyloxy)trimethylsilane (Table 3, entry 10). Oil, IR (KBr) ν (cm−1) 2957, 2899, 1602, 1519, 1456, 1415, 1346, 1251, 1203, 1097, 1014, 842, 750, 688, 644; 1H-NMR (500 MHz, CDCl3): δ (ppm) 0.11 (s, 9H, CH2OSi(CH3)3), 5.02 (s, 2H, CH2OSi(CH3)3), 7.08–7.11 (m, 3H, Ar).

(4-(Benzyloxy)benzyloxy)trimethylsilane (Table 3, entry 13). Oil, IR (KBr) ν (cm−1) 2999, 2941, 2291, 2252, 1444, 1375, 1037, 918, 842, 750; 1H-NMR (500 MHz, CDCl3): δ (ppm) 0.10 (s, 9H, CH2OSi(CH3)3), 4.73 (s, 2H, CH2OSi(CH3)3), 7.20–7.30 (m, 4H, Ar).

(4-Nitrobenzyloxy)trimethylsilane (Table 3, entry 14). Oil, IR (KBr) ν (cm−1) 3001, 2941, 2850, 2291, 1492, 1442, 1087, 1039, 918, 842, 742.634, 607; 1H-NMR (500 MHz, CDCl3): δ (ppm) 0.15 (s, 9H, OSi(CH3)3), 4.63 (s, 2H, CH2OSi(CH3)3), 5.08 (s, 2H, PhCH2O), 6.94–6.98 (m, 2H, Ar), 7.24–7.43 (m, 7H, Ar).

3 Results and discussion

First, the ability of the [C4mim][InCl4], as catalyst and reaction medium was investigated in the methoxymethylation of benzyl alcohol with formaldehyde dimethyl acetal (FDMA) and formaldehyde diethyl acetal (FDEA). The results showed that the highest yield was obtained with 1 mmol of alcohol, 5 mmol FDMA or FDEA and 1.0 mL of [C4mim][InCl4] at room temperature (Table 4).

Preparation of benzylmethoxymethyl ether with different amounts of FDMA and FDEA in [C4mim][InCl4] at room temperature.

| Entry | FDMA | FDEA | ||

| Amount (mmol) | Yield (%)a | Amount (mmol) | Yield (%)a | |

| 1 | 1 | 36 | 1 | 29 |

| 2 | 4 | 83 | 4 | 76 |

| 3 | 5 | 90 | 5 | 88 |

| 4 | 6 | 90 | 6 | 88 |

a Isolated yield.

In order to examine the catalytic activity of [C4mim][InCl4], other common Lewis acidic ionic liquids such as [C4mim][AlCl4] and [C4mim][FeCl4] were investigated for the methoxymethylation of benzyl alcohol at room temperature and under US and MW irradiations. The hydrolytic stability and reduced oxophilicity of [C4mim][InCl4], make this ionic liquid a more reactive catalyst in contrast to [C4mim][AlCl4] and [C4mim][FeCl4] (Table 5). Therefore, we concluded that the air and moisture stable Lewis acidic ionic liquid [C4mim][InCl4] is the most desirable catalyst for these protection reactions. As a control experiment, the same reactions were carried out in the absence of [C4mim][InCl4] and no MOM or EOM-ethers were observed even after heating the reaction mixture for a long period of time.

Preparation of benzylmethoxymethyl ether in the presence of different Lewis acidic imidazolium-based ionic liquids ([C4mim][X]) at room temperature, under ultrasonic and microwave irradiationsa.

| Entry | X | RT | RT | RT | |||

| Time (min) | Yield (%)b | Time (min) | Yield (%)b | Time (min) | Yield (%)b | ||

| 1 | AlCl4 | 600 | 22 | 180 | 24 | 60 | 31 |

| 2 | FeCl4 | 600 | 12 | 180 | 13 | 60 | 16 |

| 3 | InCl4 | 120 | 90 | 45 | 91 | 2 | 95 |

a Reaction conditions: benzyl alcohol (1 mmol), FDMA (5 mmol), [C4mim][X] (1 mL).

b Isolated yield.

Under these optimized conditions, the methoxymethylation and ethoxymethylation of a wide variety of structurally divergent alcohols (primary and secondary) were investigated at room temperature and under US and MW irradiations (Scheme 1). The results, which are summarized in Table 1, showed that primary and secondary alcohols were readily converted to their corresponding MOM-and EOM-ethers using [C4mim][InCl4] as catalyst and medium with excellent yields. Under the same reaction conditions, phenols and tertiary alcohols did not undergo the protection reactions even under reflux conditions, and the starting materials remained intact after 24 hours.

When the reaction mixture was exposed to US irradiation, the reaction times reduced and the yields increased. It seems that in the homogeneous systems, the main effect of US irradiation in these reactions is due to the cavitation phenomenon [20,21].

It was expected that the ionic structure of [C4mim][InCl4] makes it an efficient substrate for quick heating under microwave irradiation. Most of the ionic liquids remain stable up to at least 160 °C under microwave irradiation [16]. Optimized microwave power was 100 W (Table 6) and temperature reached to 80–90 °C under this output power of irradiation. At this power, [C4mim][InCl4] was not decomposed and no decrease in its catalytic activity was observed. The results showed that under MW irradiation, the yields are higher and the reaction times are shorter in comparison with thermal conditions and ultrasonic irradiation (Table 1).

Optimization of microwave power for the synthesis of benzylmethoxymethyl ether in [C4mim][InCl4].

| Row | MW power (W) | Yield (%)a | T (°C) | Time (min) |

| 1 | 80 | 79 | 63 | 4 |

| 2 | 95 | 92 | 74 | 4 |

| 3 | 100 | 95 | 80 | 2 |

| 4 | 150 | 95 | 104 | 2 |

a Isolated yield.

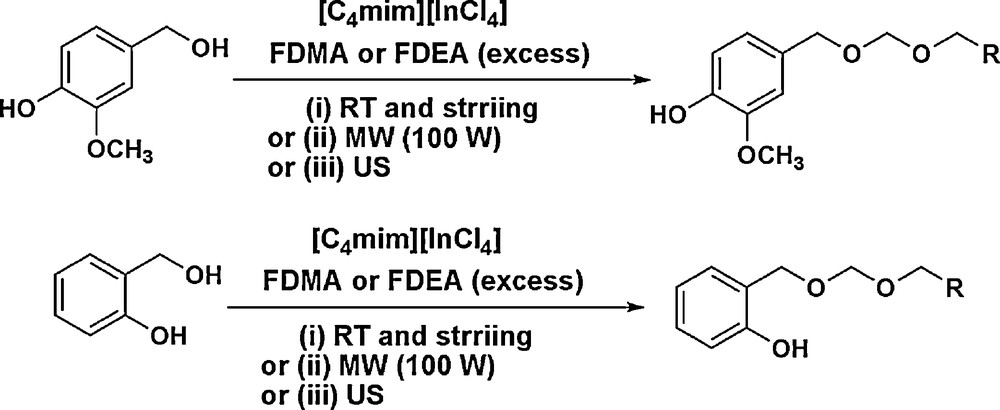

It is noteworthy that in compounds containing both benzylic and phenolic hydroxyl groups (Table 1, entries 3 and 4); only the benzylic hydroxyl group was converted to its corresponding MOM-or EOM-ether with excellent chemoselectivity (Scheme 3). This observation encouraged us to investigate the chemoselectivity of the presented method in a set of competitive reactions between primary or secondary alcohols and phenols or tertiary alcohols. The results indicated that the present protocol is potentially applicable for the chemoselective conversion of primary and secondary alcohols to their MOM-and EOM-ethers in the presence of phenols and tertiary alcohols under different reaction conditions (Table 7). In an equimolar binary mixture of primary alcohol with phenol or tertiary alcohol, only primary alcohol was converted to the corresponding MOM-and EOM-ethers (Table 7, entries 1 and 3). Selective conversion of secondary alcohol to the corresponding MOM-and EOM-ethers in the presence of phenol or tertiary alcohol was also achieved under these conditions (Table 7, entries 2, 4).

Competitive protection of alcohols and phenols with FDMA and FDEA in [C4mim][InCl4] at room temperaturea.

| Entry | Substrates | Productb | R | Yield (%)c | Time (min) |

| 1 | H Me | 90 88 | 120 | ||

| 2 | H Me | 93 87 | 195 | ||

| 3 | H Me | 90 88 | 120 | ||

| 4 | H Me | 93 87 | 195 |

a Reaction conditions: alcohol (1 mmol), phenol (1 mmol), FDMA or FEDA (5 mmol) and [C4mim][InCl4] (1 mL).

b Phenol and tertiary alcohol remained intact in the reaction mixture.

c Isolated yield.

Reusability of the [C4mim][InCl4] is an important issue in the context of economic feasibility and sustainable development. Therefore, the investigation of the possibility of recycling and reusing the catalyst was carried out using methoxymethylation of benzyl alcohol with FDMA. The recycling study showed that the catalyst can be recycled several times at room temperature only with a slight decrease in its activity (Table 8). While, under MW irradiation, it was possible to reuse the [C4mim][InCl4] two times. However, under ultrasonic irradiation conditions, [C4mim][InCl4] was decomposed after the first run (Table 8).

Recycling of [C4mim][InCl4] in the preparation of benzylmethoxymethyl ether at room temperature, under microwave and ultrasonic irradiations.

| Run | RT | MW | US | |||

| Yield (%)a | Time (min) | Yield (%)a | Time (min) | Yield (%)a | Time (min) | |

| 1 | 90 | 120 | 95 | 2 | 91 | 3 |

| 2 | 90 | 120 | 89 | 2 | ||

| 3 | 88 | 120 | 81 | 2 | ||

| 4 | 86 | 120 | ||||

| 5 | 83 | 120 |

a Isolated yield.

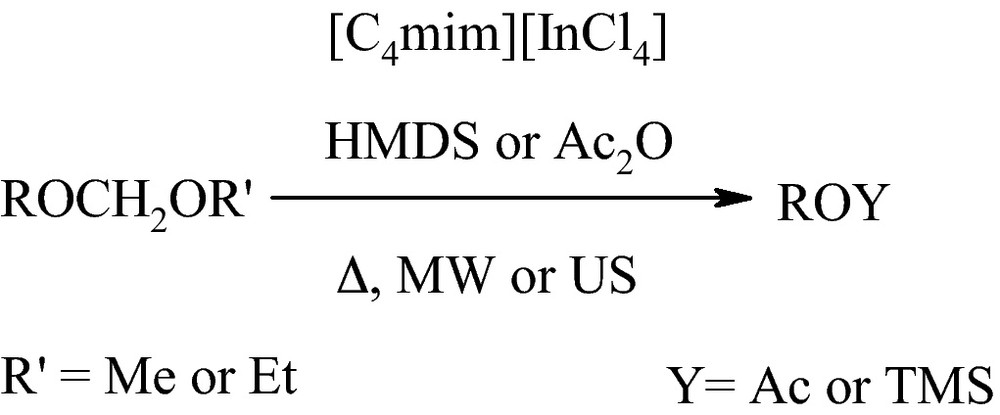

Then, the ability of [C4mim][InCl4], as catalyst and medium, was investigated for transformation of MOM-and EOM-ethers to other hydroxyl-protecting groups such as acetates and TMS ethers. These reactions were also performed under three different conditions: thermal conditions and ultrasonic and microwave irradiations (Scheme 2). These reactions were carried out using acetic anhydride (Ac2O) and HMDS as protecting agents.

In order to optimize the amounts of Ac2O and HMDS, direct transformation of benzylmethoxymethyl ether (1 mmol) to its corresponding acetate and TMS-ether with acetic anhydride and HMDS in [C4mim][InCl4] were chosen as model reactions. The best results were obtained with 5 mmol Ac2O or HMDS in 1.0 mL of [C4mim][InCl4] under thermal conditions, ultrasonic and microwave irradiation (Table 9). The reaction temperature and MW power were also optimized in these reactions. As shown in Tables 10 and 11, the best results were obtained at 80 °C for thermal conditions and at 160 W (145–147 °C) for MW irradiation.

Optimization of Ac2O and HMDS amounts in the interconversion of benzylmethoxymethyl ether to the corresponding acetate and TMS-ether in [C4mim][InCl4] under thermal conditions.

| Protecting agent (mmol) | Ac2O | HMDS | ||

| Yield (%)a | Time (min) | Yield (%)a | Time (min) | |

| 1 | 10 | 180 | 19 | 195 |

| 2 | 34 | 180 | 35 | 195 |

| 3 | 54 | 180 | 49 | 195 |

| 4 | 73 | 180 | 68 | 195 |

| 5 | 87 | 180 | 84 | 195 |

| 5.5 | 87 | 180 | 84 | 195 |

a Isolated yield.

Optimization of reaction temperature for the interconversion of benzylmethoxymethyl ether to the corresponding acetate and TMS-ether in [C4mim][InCl4]a.

| Entry | T (°C) | Acetate | TMS-ether | ||

| Yield (%)b | Time (min) | Yield (%)b | Time (min) | ||

| 1 | RT | 39 | 300 | 41 | 300 |

| 2 | 50 | 61 | 300 | 59 | 300 |

| 3 | 75 | 82 | 240 | 79 | 300 |

| 4 | 80 | 87 | 180 | 84 | 195 |

| 5 | 100 | 87 | 180 | 84 | 195 |

a Reaction conditions: Alkoxymethyl ether (1 mmol), Ac2O or HMDS (5 mmol), [C4mim][InCl4] (1 mL).

b Isolated yield.

Optimization of microwave power for interconversion of benzylmethoxymethyl ether to the corresponding acetate and TMS-ether in [C4mim][InCl4].

| Entry | MW power (W) | Acetate | TMS-ether | ||

| Yield (%)a | T (°C) | Yield (%)a | T (°C) | ||

| 1 | 130 | 85 | 133 | 86 | 130 |

| 2 | 155 | 90 | 143 | 90 | 141 |

| 3 | 160 | 92 | 147 | 94 | 145 |

| 4 | 180 | 92 | 150 | 94 | 147 |

a Isolated yield.

Under these optimized conditions, a wide range of methoxymethyl and ethoxymethyl ethers were subjected to trimethylsilylation and acetylation in the presence of [C4mim][InCl4] under thermal conditions, US and MW irradiations. The results are shown in Tables 2 and 3. It was observed that a wide range of aryl MOM- or EOM-ethers containing electron-withdrawing as well as electron-donating groups such as chloro, bromo, nitro, methoxy, hydroxy, t-butyl, and benzyloxy and also primary and secondary MOM- or EOM-ethers easily underwent one-pot interconversion with acetic anhydride or HMDS to give the corresponding acetates or TMS-ethers, respectively, with excellent isolated yields.

It is also noteworthy that in the conversion of alkoxymethyl ethers bearing aromatic rings to their corresponding acetates no Friedel-Crafts reaction was observed (Table 2, entries 1–16).

The experimental procedure for these transformations is remarkably simple and requires no toxic organic solvents or inert atmospheres. However, the synthesis could not be achieved in the absence of the ionic liquid. The use of [C4mim][InCl4] helps to achieve a green and economic process.

In order to explore the general applicability of this method further, several competitive transformations were also investigated using this catalyst. As can be seen, interesting selectivities were observed. In an equimolar mixture of primary or secondary MOM-or EOM-ether and phenolic MOM-or EOM-ether, primary and secondary ethers were selectively transformed to their corresponding acetates (Table 12, entries 1 and 2) and TMS-ethers (Table 12, entries 5 and 6). Selective interconversion of primary and secondary MOM-or EOM-ether to the corresponding acetates and TMS-ethers were also achieved in the presence of tertiary MOM-or EOM-ether (Table 12, entries 3, 4, 7 and 8). Furthermore, this method can be selectively applied for the chemoselective interconversion of these ethers in the presence of the other hydroxyl-protecting groups such as methyl ether (Tables 2 and 3, entries 4–6) and benzyl ether (Tables 2 and 3, entry 13). These selectivities can be considered as useful practical achievements in these interconversion reactions.

Competitive acetylation of EOM- and MOM-ethers of alcohols and phenols under thermal conditions, ultrasonic and microwave irradiationsa.

| Entry | Substrates | Productb | R | Yield (%)c | Time (min) | ||||

| Heat | MW | US | Heat | MW | US | ||||

| 1 | Et Me | 85 87 | 91 92 | 88 90 | 180 180 | 3.5 3.5 | 60 60 | ||

| 2 | Et Me | 83 85 | 86 86 | 87 90 | 240 240 | 7.5 7.5 | 60 60 | ||

| 3 | Et Me | 85 87 | 91 92 | 88 90 | 180 180 | 3.5 3.5 | 60 60 | ||

| 4 | Et Me | 83 85 | 86 86 | 87 90 | 240 240 | 7.5 7.5 | 60 60 | ||

| 5 | Et Me | 85 84 | 89 88 | 84 86 | 165 165 | 4 4 | 75 75 | ||

| 6 | Et Me | 81 82 | 86 86 | 82 84 | 270 270 | 8.5 8.5 | 120 120 | ||

| 7 | Et Me | 85 84 | 89 88 | 84 86 | 165 165 | 4 4 | 75 75 | ||

| 8 | Et Me | 81 82 | 86 86 | 82 84 | 270 270 | 8.5 8.5 | 120 120 |

a Reaction conditions: MOM- or EOM-ether (1 mmol), acetic anhydride (5 mmol), [C4mim][InCl4] (1 mL).

b Protected phenol and tertiary alcohol remained intact in reactions mixture.

c Isolated yield.

4 Conclusion

In conclusion, we have developed a mild, ecofriendly, simple, and efficient method for the protection of primary and secondary alcohols to their corresponding MOM-and EOM-ethers at room temperature by FDMA and FDEA, respectively, and also direct and one-pot transformation of these ethers to their acetates and TMS-ethers under thermal conditions, ultrasonic and microwave irradiations using [C4mim][InCl4] as a green catalyst and medium. The ionic nature of the catalyst causes the great acceleration of reaction under microwave irradiation. Operational simplicity, short reaction times, the use of an efficient and reusable catalyst, excellent yields and high degree of chemoselectivity are the main advantages of the present method.

Acknowledgment

The authors are grateful to the Center of Excellence of Chemistry of University of Isfahan and also Research Council of University of Isfahan for financial support of this work.