1 Introduction

Nitrosoarenes which belongs to the general class of C-nitroso chemical compounds, are used for the synthesis of some organic intermediates [1,2]. These compounds have also found applications in analysis as reagent [1,2]. The nitrosoarenes are known to bind to metal centers and consequently have various biological applications. These compounds are able to bind to the heme biomolecules such as hemoglobin (Hb) and myoglobin (Mb) which contain histidine-liganded hemes [3]. Nitrosating agents have low electrophilicity in comparison with nitration reagents. Therefore fewer reports have been published about the nitrosation reaction in comparison with nitration reaction. Nitrous acid is the mostly used reagent for the synthesis of nitrosoarenes via the electrophilic aromatic nitrosation reaction [3]. The aromatic nitroso-compounds which were prepared using nitrous acid, can be decomposed by oxidation by NO2 [4] or by nitration with nitric acid which was produced from the aerobic oxidation of nitrous acid [5]. Nitrosonium ethyl sulfate has been used as nitrosonium source reagent for the synthesis of nitrosoarenes via the nitrosation of O-alkylphenols and N,N-dialkylanilines [2]. Zolfigol and co-workers reported the N-nitrosation of secondary amines using [NO+·Crown·H(NO3)2−] as anitrosonium source [6]. Didier Roche et al. used a practical polymer-supported nitrosation reagent for the N-nitrosation reaction [7].

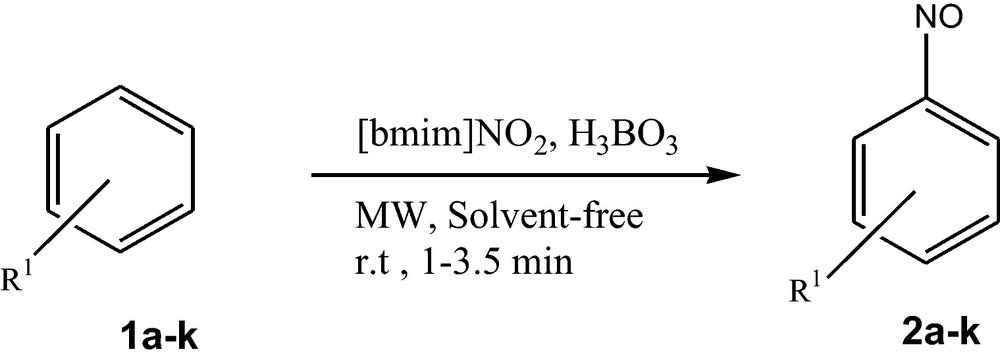

Weak coordination of organic cations such as 1-butyl-3-methylimidazolium, N-alkylpyridinium or tetraalkylammonium with inorganic anions such as Cl−, BF4− or HSO4− produced ionic liquids, which have attracted the chemist's interest due to their interesting physical and chemical properties [8,9]. Many of these compounds known as task-specific ionic liquids (TSILs) are able to play multiple roles as catalyst and/or reagent and solvent have been reported in the literature. TSILs contain functional groups which are covalently bonded to cation or anion in these compounds. TSILs have been increasingly used in synthetic organic chemistry [10–14]. Since the ionic nature of IL's, these compounds absorb very efficiently MW irradiation and can increase the rate of the organic reactions. Boric acid has been used as catalyst for the synthesis of organic compounds such as bis(indolyl)methanes [15], 3,4-dihydropyrimidin-2(1H)-ones [16], unsaturated polyesters [17] and 2-amino-3,5-dicarbonitrile-6-thio-pyridines [18]. In continuation of our interest to use ionic liquids (IL's), water or solventless systems as green reaction medium [19], in this report, we wish to highlight our results on using [bmim]NO2/H3BO3 in nitrosation of aromatic compounds to produce nitrosoarenes in good to excellent yields at room temperature under MW-assisted solvent-free conditions (Scheme 1).

MW-promoted solvent-free C-nitrosation using [bmim]NO2/H3BO3.

2 Results and discussion

The ionic liquid, [bmim]Cl was readily prepared from commercially available starting materials and reagents in good yields [20]. The exchange of Cl− by NO2− in the presence of NaNO2 at room temperature afforded nitrite ionic liquid, [bmim]NO2 in 91% yield. [bmim]NO2 was purified by drying in a vacuum at 80 °C to remove the residual starting materials and reagents. Nitrosation of N,N-dimethylaniline was chosen as a model reaction. The activity of the nitrite ionic liquid as nitrosonium source was examined for the model reaction in the presence of HCl 37% at room temperature under heterogeneous aqueous media. The experimental results revealed that [bmim]NO2 exhibits good activity and 4-nitroso-N,N-dimethylaniline 2a was prepared in 62% yield over 2 h. Several acids such as AlCl3, H2SO4, ZnCl2 and H3BO3 were examined in this procedure and the best results were found using boric acid. Microwave irradiation was also examined in this protocol and showed that high yield of product in shorter reaction time was produced. One-pot reaction of N,N-dimethylaniline, ionic liquid and H3BO3 under MW-assisted solvent-free conditions afforded the product 2a in 94% yield in 1.5 min. Optimization of the reaction conditions was studied with different molar ratios of the ionic liquid, N,N-diethylaniline and H3BO3. The best ratio was found to be 1.1:1:1.25. Optimized conditions used, [bmim]NO2 was examined for the nitrosation of other aromatic compounds. As can be seen from Table 1, active aromatic compounds, containing electron-releasing groups react faster and afforded the related nitroso products in higher yields in comparison with toluene. The aromatic compounds containing electron withdrawing group nitrosated in very lower yield under the same conditions. Phenol, phenethol, N,N-dialkylanilines, and anisole were nitrosated regioselectively at 4 position as showed in Table 1. β-Naphthol nitrosated regioselectively at the α position. α-Naphthol was nitrosated at 2 and 4 positions with a 74:26 ratio (Table 1, entry 4). Despite the previous reports, the nitroso products were stable during the reaction and no oxidized nitro product was observed under these conditions [5]. Dealkylation has been very often observed in the nitrosation of alkyl phenyl ethers [21]. However, using the [bmim]NO2/H3BO3 for the nitrosation of anisole and phenethol in virtually afforded to related pure nitroso products, and the reactions were not accompanied by dealkylation. All of products were characterized by comparing their (1H, 13C NMR and IR) spectroscopic data and melting points with literature values.

MW-promoted electrophilic aromatic nitrosation using [bmim]NO2/H3BO3 under solvent-free conditions.

| Entry | Ar-H | Product | M.P (lit [Ref.]) (°C) | |

| Found | Reported [Ref.] | |||

| 1 | 92–94 | 92 [2] | ||

| 2 | 103–106 | 103–105 [22] | ||

| 3 | 135–138 | 135–138 [23] | ||

| 4 | 155–157 | 155–157 [24] | ||

| 5 | 82–84 | 82–84 [2] | ||

| 6 | 70–73 | 71–72 [2] | ||

| 7 | 35–36 | 34–35 [23] | ||

| 8 | Liquid | 23 [25] | ||

| 9 | 156–159 | – | ||

| 10 | 156–158 | 160–162 [26] | ||

| 11 | – | 47 [27] |

In summary, it was found that [bmim]NO2/H3BO3 is a highly effective, mild and convenient reagent for the one-pot electrophilic aromatic nitrosation of aromatic compounds. Side processes such as oxidation or dealkylation were not observed during the nitrosation in the presence of this new reagent. Regioselectivity, easy and clean work-up procedure, very short reaction times and excellent yields are the advantages of this method. For comparison, the reaction time and yield of products via the present method and other reported methods were gathered in Table 2. An additional advantage of this method is the creation of nitrosoarenes using a one-pot simple synthesis.

Comparison of the times and yields of the present method with reported methods.

| Product number | Time (min) | Yield (%) | ||

| Found | Reported [Ref.] | Found | Reported [Ref.] | |

| 2a | 1.5 | – | 94 | 87 [2] |

| 2b | 2.5 | 60–75 [22] | 94 | 99 [22] |

| 2c | 2 | 30 [28] | 91 | 85–90 [28] |

| 2d | 2.5 | – | 72 | 99.4 [24] |

| 2e | 1.5 | – | 92 | 96 [2] |

| 2f | 1.5 | – | 92 | 81 [2] |

| 2g | 1.75 | – | 96 | 50 [23] |

| 2j | 1.5 | 85 [26] | 58 | 80 [26] |

| 2k | 3.5 | 20 [27] | 63 | 88 [27] |

3 Experimental

3.1 General information

All reagents were purchased from Merck Company and used without further purification. Infrared spectra were recorded in KBr and were determined on a Perkin Elmer FT-IR spectrometer. 1H NMR spectra were recorded on a Bruker Avance AC- 400 MHz using TMS as internal standard. All melting points measured in open glass-capillaries using Stuart melting point apparatus.

3.2 Preparation of 1-butyl-3-methylimidazolium nitrite

1-Butyl-3-methylimidazolium chloride was prepared from the reaction of N-methylimidazole with n-butylchloride at 80 °C under neat conditions. Sodium nitrite (23 mmol) was added to a solution of this freshly prepared ionic liquid (20 mmol) in dichlorometrhane (10 mL) and stirred for 24 h at room temperature. The suspension was filtered to remove the precipitated sodium chloride salt and the organic layer washed with water (3 × 5 mL) until no precipitation of AgCl occurred in aqueous phase on addition of a concentrated AgNO3 solution. The solvent and other volatile materials were removed from organic layer in vacue and the resulting ionic liquid was stirred with activated charcoal for 12 h, after which the ionic liquid was passed through a short alumina column(s) (acidic and/or neutral) to give a colorless ionic liquid, which was dried at 100 °C in vacue for 24 h or until no visible signs of water present in the IR spectrum. Yields generally 78–82%. IR (KBr): 1652, 1617, 1532, 1350, 1190 cm−1; 1H NMR (400 MHz, CDCl3) δ 1.05 (3H, t, –CH3), 1.41 (2H, m, CH2), 1.76 (2H, m, CH2), 3.83 (3H, s, N–CH3), 3.97 (2H, t, –N–CH2), 7.21 (1H, d, Ar–H), 7.40 (1H, d, Ar–H), 9.12 (1H, broad, Ar–H). 13C NMR (100 MHz, CDCl3) 11.7, 18.3, 25.6, 36.4, 37.8, 124.7, 126.8, 140.0. Anal. Calcd (%) for C8H15N3O2: C, 51.88; H, 8.16; N, 22.69. Found (%): C, 52.12; H, 8.21; N, 22.58.

3.3 Electrophilic aromatic nitrosation using [bmim]NO2/H3BO3, general procedure

Aromatic compound (15 mmol) and [bmim]NO2 (16.5 mmol) and H3BO3 (18.75 mmol) were mixed thoroughly. The mixture was subjected to MW irradiation at 60 W for a few minutes (depending on the reactants, Table 1). The completion of reaction was monitored by TLC using (EtOAc/petroleum 1:6) as eluent and the product was isolated via flash chromatography from EtOAc/petroleum ether as eluent.

4 Selected spectroscopic data

2-Nitrosonaphthalen-2-ol (2b): IR (KBr) (νmax/cm−1): 3405 (OH), 1625 (N=O), 1600 (C=C); 1H NMR (400 MHz, CDCl3) δ: 14.08 (s, 1H, OH), 7.65 (d, 1H, J = 7.50 Hz), 7.49–7.61 (m, 4H), 6.39 (d, 1H, J = 7.50 Hz).

2-Nitrosonaphthalen-1-ol (2d): IR (KBr) (νmax/cm−1): 3201 (OH), 1669 (N=O), 1627 (C=C); 1H NMR (400 MHz, DMSO-d6) δ: 13.89 (s, 1H, OH), 7.61–7.81 (m, 4H), 7.01 (d, 1H, J = 7.35 Hz), 7.13 (d, 1H, J = 7.35 Hz).

2-Nitrosobenzene-1,4-diol (2i): IR (KBr) (νmax/cm−1): 3221 (OH), 1631 (N=O), 1600 (C=C); 1H NMR (400 MHz, DMSO-d6) δ: 11.63 (s, 1H, OH), 6.88 (s, 2H, OH, Harom), 6.80 (d, 1H, J = 7.41 Hz), 6.74 (d, 1H, J = 7.41 Hz).

5-Methyl-2-nitrosophenol (2j): IR (KBr) (νmax/cm−1): 3120 (OH), 1633 (N=O), 1594 (C=C); 1H NMR (400 MHz, DMSO-d6) δ: 13.5 (s, 1H, OH), 7.61 (d, 1H, J = 9.89 Hz), 6.37 (dd, 1H, J = 2.41 and 9.89 Hz), 6.32 (d, 1H, J = 2.41 Hz), 2.09 (s, 3H, CH3).

Acknowledgement

The partial financial assistance from the Research Vice Chancellor of Azarbaijan University of Tarbiat Moallem is gratefully acknowledged.