1 Introduction

Ionic liquids (IL) have been regarded as the important classes of compounds, and have also been widely used because of their non-flammability, high thermal and chemical stability, large electrochemical window, wide liquid-state temperature range, non-volatility, negligible vapor pressure, favorable solvation behaviors, and the ability to dissolve a wide range of materials. Also, ILs have received considerable interest as eco-friendly solvents [1–5]. It is worth mentioning that the different kinds of BAILs, which add the useful characteristics of solid acids and mineral liquid acids, have been designed to replace traditional mineral acids like sulfuric acid (H2SO4) and hydrochloric acid (HCl) in chemical procedures [6–10].

Moreover, ILs have been extensively applied in some other fields such as the formation of metal nanostructures [11], sensors [12], catalysis [13], analytical chemistry [14], bioanalytical chemistry [15], in basic electrochemical studies of organic compounds and inorganic compounds [16], electrochemical biosensors [17], extraction and separation processes in industry [18]. In addition to the above applications, they are also used in several chemical reactions such as condensation, esterification, alkylation, dehydration, and synthesis of pharmaceutical products (from both laboratory and industrial scales) [19].

Epoxides and their derivatives are the most useful synthetic intermediates in organic synthesis [20]. The synthesis of 2-azidoalcohols has been of considerable interest to chemists because of their usefulness for the synthesis of amino sugars [21], lactames [22], oxazolines [23], and carboxylic nucleosides [24]. They are also useful for the synthesis of vicinal aminoalcohols [25] and precursors of aminoalcohols, which are well known as β-blockers existing in numerous natural products and different bioactive compounds [26]. Several catalysts and methods have been reported for the synthesis of 2-azidoalcohols in the presence of sodium azide, such as NaN3/LiBF4 [27], NaN3/(TBA)4PFeW11O39.3H2O [28], NaN3/Oxon [29], NaN3/PVA (poly vinylamine) or PAA (poly allylamine [30], 1-hydrogen-3-methylimidazolium azide [31], NaN3/CeCl3 [32], NaN3/LiC1O4, NaN3/NH4Cl/MeOHH2O, NaN3/Mg(ClO4)2/CH3CN [33], Nano-Fe3O4-PS-Co-[PAA-g-PEG [34], tributyltin azide [35], NaN3/calcium cation exchange Y-type Zeolite [36], [pbmim](FeCl4)2 [37], diethylaluminium azide [38], NaN3/CAN [39], 1-(1-Alkylsulfonic)-3-methylimidazolium chloride [40], β-cyclodextrine/TMSN3 [41], and Network Polymer/NaN3 [42].

Although some of the reported methods and catalysts are known, still some of these methods suffer from drawbacks such as long reaction times, use of expensive catalysts, high temperature, high cost for the preparation of catalyst, use of solvent or catalyst toxic, and tedious workup. So, the search for finding green and simple catalysts and methods is still of significance. The main objectives of green chemistry are avoidance of toxic solvent and reagents, avoidance of high cost for preparation of catalysts, and the reduction of costs associated with organic synthesis.

Considering the above reports, it seems that in the case of 1,2-azidoalcohols derivatives we still need to develop new methods for using an inexpensive, green, recyclable, and environmentally friendly reagent. Therefore, it seems that the present research is more acceptable because the new method has several advantages such as, solvent-free reaction conditions, using low temperature for complete reaction, high regioselectivity, easy synthesis of reagent, recyclability of ionic liquids, and clean reactions. Here in the following report, two new BAILs functionalized with an acetic acid (Fig. 1) have been shown.

Structures of acetic acid functionalized imidazolium salts.

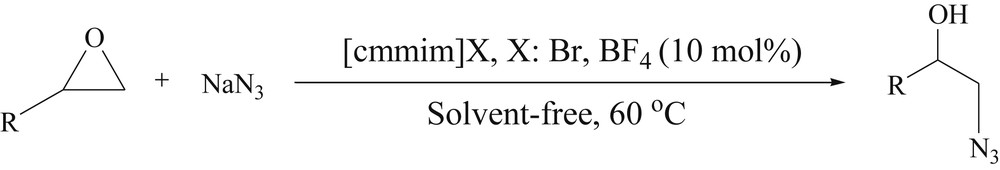

In continuation of our previous studies to develop environmentally benign methods using green catalysts for organic synthesis [43–46], we report herein an efficient, green, convenient, and simple procedure for the regioselective conversion of some epoxides with sodium azide in the presence of a acetic acid functionalized imidazolium salt [(cmmim)Br or (cmmim)BF4] as a green and reusable Brønsted acidic ionic liquid catalyst under solvent-free conditions at 60 °C, which afforded the corresponding 1,2-azidoalcohols in excellent yield and short reaction time (Scheme 1).

Regioselective azidolysis of epoxides using acetic acid functionalized imidazolium salts.

2 Experimental

2.1 General

All of the solvents and reagents were purchased from Aldrich and Merck with high-grade quality and used without any purification. The products were identified by comparison of their melting points (MP) and spectral data in the literature. 1H NMR (400 MHz) and 13C NMR (100 MHz) spectra were recorded on a Bruker Avance (400 MHz) spectrometer using CDCl3 as the solvent and TMS as an internal standard. Melting points were taken on an Electrothermal capillary melting point apparatus and are uncorrected. The progress of reaction was followed with thin-layer chromatography (TLC) using a silica gel SILG/UV 254 and 365 plate.

2.2 General procedure for the synthesis of acetic acid functionalized imidazolium salts

1-Carboxymethyl-3-methylimidazolium bromide [cmmim]Br 1a and 1-carboxymethy1-3-methylimidazolium tetrafluoroborate [cmmim]BF4 1b were prepared according to the literature procedure [47–49].

2.3 Reactions of epoxides with NaN3 catalyzed acetic acid functionalized imidazolium salts

A mixture of epoxide (1 mmol), NaN3 (1.1 mmol), and BAILs 1a and 1b (0.1 mmol, 10 mol %) was heated at 60 °C with good stirring for the appropriate time mentioned in Table 4. After complete consumption of the epoxide as judged by TLC (using n-hexane/ethylacetate (5:1) as the eluent), the catalyst was recovered for reuse by simple filtration, and the product was extracted with ethyl acetate (3 × 5 mL). The extract was dried over anhydrous Na2SO4 and concentrated under vacuum to obtain β-hydroxyazide in 85–95% and 86–96% isolated yields. For styrene oxide, further purification was achieved by preparative TLC or by silica gel column chromatography. The spectral data of all the products were identical to those of the authentic samples.

Azidolysis of epoxides with sodium azide using [Cmmim]Br and [Cmmim]BF4.a

| Entry | Product(s) | [Cmmim]Br | [Cmmim]BF4 | ||

| Time (min) | Yield (%)b | Time (min) | Yield (%)b | ||

| 1 | 15 | 96 | 15 | 95 | |

| 2 | 18 | 90(10:90) | 20 | 91(10:90) | |

| 3 | 20 | 90 | 20 | 91 | |

| 4 | 25 | 93 | 27 | 94 | |

| 5 | 20 | 90 | 20 | 88 | |

| 6 | 25 | 88 | 20 | 90 | |

| 7 | 25 | 90 | 25 | 88 | |

| 8 | 30 | 93 | 30 | 95 | |

| 9 | 35 | 89 | 35 | 89 | |

| 10 | 20 | 87 | 25 | 85 | |

| 11 | 20 | 91 | 30 | 90 | |

| 12 | 20 | 86 | 25 | 89 |

a Products were identified by comparison of their spectral data (1H NMR,13C NMR, and IR) with those of authentic samples.

b Yield of isolated products.

2.3.1 1-Azido-3-phenoxy-2-propanol [37]

IR νmax/cm−1: 2103 (N3); 1H NMR (CDCl3, 400 MHz): δ = 3.45–3.54 (2H, m), 3.89 (1H, m), 3.97–4.03 (2H, m), 4.18 (1H, s), 6.95–7.00 (m, 2H), 7.02–7.06 (m, 1H), 7.27–7.36 (m, 2H); 13C NMR (CDCl3, 100 MHz): δ = 53.5, 69.2, 69.3, 114.3, 121.1, 129.4, 158.3.

2.3.2 2-Azido-2-phenyl-1-ethanol [37]

IR νmax/cm−1: 2102 (N3); 1H NMR (CDCl3, 400 MHz): δ = 3.37 (1H, s), 3.74 (2H, m), 4.65–4.69 (1H, m), 7.34–7.44 (5H, m); 13C NMR (CDCl3, 100 MHz): δ = 66.3, 68.0, 127.4, 128.4, 128.6, 136.4.

2.3.3 1-Azido-3-butoxy-2-propanol [37]

IR νmax/cm−1: 2102 (N3); 1H NMR (CDCl3, 400 MHz): δ = 0.87 (3H, t), 1.31–1.35 (2H, m), 1.50–1.53 (2H, m), 3.14 (1H, s), 3.30–3.32 (2H, m), 3.39–3.44 (4H, m), 3.87 (1H, m); 13C NMR (CDCl3, 100 MHz): δ = 13.78, 19.16, 30.74, 53.52, 69.74, 70.59, 70.71.

3 Results and discussion

BAILs 1a and 1b were prepared according to the literature procedure [47–49]. BAILs 1a and 1b were also characterized by thermal gravimetric analysis (TGA), X-ray diffraction analysis (XRD), differential thermal gravimetry (DTG), and Fourier transform infrared spectroscopy (FT-IR) analysis [47–49]. We, herein, report the use of an acetic acid functionalized imidazolium salt [Cmmim]BF4 or [Cmmim]Br as an ecofriendly, inexpensive, and recyclable catalyst for the synthesis of 1,2-azidoalcohols by regioselective ring opening of some epoxides with sodium azide under mild and neutral reaction conditions at 60 °C (Scheme 1).

In the first step, in order to optimize the catalyst for the preparation of 2-zzido-2-phenyl-1-ethanol, the reaction of phenyl glycidyl ether (1 mmol) with NaN3 (1.1 mmol) under solvent-free conditions using different amounts of BAIL 1a was chosen as a model reaction in promoting the 1,2-azidoalcohols. The results are presented in Table 1. First, the reaction was performed in the absence of a catalyst, and after 24 h, no product was obtained (Table 1, entry 1). It was found that 10 mol % of the BAIL 1a under solvent-free conditions at room temperature gave 2-azido-2-phenyl-1-ethanol in 91% yield and 25 min (Table 1, entry 5). Moreover, the lower yield of 2-azido-2-phenyl-1-ethanol can be reached by increasing the amount of the catalyst (Table 1, entry 7).

Effect of catalyst on azidolysis of phenyl glycidyl ether (1 mmol) with NaN3 (1.1 mmol) under solvent-free conditions at room temperature.

| Entry | Catalyst amount (mol %) | Time (min) | Yield (%)a |

| 1 | None | 24 h | Trace |

| 2 | 1 | 45 | 81 |

| 3 | 5 | 40 | 85 |

| 4 | 7 | 40 | 86 |

| 5 | 10 | 25 | 91 |

| 6 | 15 | 25 | 91 |

| 7 | 20 | 25 | 88 |

a Yield of isolated products.

In the second step, the model reaction was tested using different temperatures and was obtained in good to excellent yields under solvent-free conditions (Table 2). As it can be seen in Table 2, the best results were obtained when the reaction was performed at 60 °C (Table 2, entry 1). Increasing the reaction temperature did not improve the results and neither increased the yield nor lowered the conversion time (Table 2, entries 4–5).

Determination of the optimum conditions for the pseudo three-component coupling reaction of phenyl glycidyl ether (1 mmol) and NaN3 (1.1 mmol) under thermal solvent-free conditions.

| Entry | Temperature (°C) | Time (min) | Yield (%)a |

| 1 | 60 | 15 | 96 |

| 2 | 80 | 20 | 90 |

| 3 | 90 | 20 | 90 |

| 4 | 100 | 30 | 87 |

| 5 | 120 | 35 | 83 |

a Yield of isolated products.

After optimization of reaction conditions, the reaction was examined in the presence of various catalysts including citric acid, cyanuric chloride, acetic acid, oxalic acid, and silica gel under solvent-free conditions at 60 °C, and the results are summarized in Table 3. Higher yield and short reaction time of product were obtained when an acetic acid functionalized imidazolium salt [Cmmim]BF4 or [Cmmim]Br was utilized as the catalyst (Table 3, entry 6). Therefore, this reaction was developed with various aromatic and aliphatic epoxides with sodium azide in the presence of Brønsted acidic ionic liquids 1a and 1b under solvent-free conditions at 60 °C, and the results are summarized in Table 4.

Effect of various catalysts on the condensation of phenyl glycidyl ether (1 mmol) with NaN3 (1.1 mmol) under solvent-free conditions at 60 °C.

| Entry | Catalyst | Time (min) | Yield (%)a |

| 1 | Citric acid | 120 | 58 |

| 2 | Cyanuric chloride | 120 | 60 |

| 3 | Acetic acid | 150 | 65 |

| 4 | Oxalic acid | 150 | 61 |

| 5 | Silica gel | 180 | Not completed reaction |

| 6 | [Cmmim]Br | 15 | 96 |

a Yield of isolated products.

As can be seen in Table 4, to ascertain the scope and limitation of the present reaction, various aliphatic epoxides reacted with sodium azide using BAIL 1a and BAIL 1b under solvent-free conditions at 60 °C to produce the corresponding 2-azidoalcohols in excellent yields and a short reaction time. Reaction with bicyclic epoxides such as cyclohexene epoxide, cyclopentene epoxide, and cyclooctene epoxide afforded 2-azidoalcohols in an excellent and short reaction time. The structures of 1,2-azidoalcohol products were characterized by IR, 1H NMR and 13C NMR spectral data, and physical properties were compared with the literature values of known compounds.

One of the characteristics of ionic liquids is recovery and reusability. Thus, the recovery and reusability of BAILs 1a and 1b for the condensation of phenyl glycidyl ether (1 mmol) with sodium azide (1.1 mmol) under solvent-free conditions at 60 °C as a model reaction was investigated; the results are shown in Table 5. As can be seen in Table 5, the recovery and reusability for two ionic liquid was tested, after completion of the reaction; the catalyst was recovered by filtration and reused yields remained unchanged.

The reusability of [Cmmim]Br and [Cmmim]BF4 for the preparation of 1-azido-3-phenoxy-2-propanol.

| Product | Total reusability | [Cmmim]Br | [Cmmim]BF4 |

| Yield (%) | Yield (%) | ||

| 1 | 96 | 95 | |

| 2 | 95 | 95 | |

| 3 | 95 | 93 | |

| 4 | 93 | 92 | |

| 5 | 91 | 90 |

In another study, to show the merit of the our work for the synthesis of 1,2-azidoalcohols of phenyl glycidyl ether (1 mmol) with NaN3 (1.1 mmol) under solvent-free conditions at 60 °C in the presence of BAILs 1a and 1b was selected as a model reaction, and were compared with other catalysts such LiBF4, (TBA)4PFeW11O39·3H2O, NaN3/NH4Cl, NaN3/Mg(ClO4)2, NaN3/LiClO4, 3D-network polymer, PTC, SiO2-PEG-ImBr, sulfuric acid, and MPTC. The results are summarized in Table 6. Each of these methods often suffer from some troubles such as long reaction times and tediousness for the completion of the reaction (Table 6, entries 2–7), use of organic solvents under reflux conditions (hard reaction conditions) (Table 6, entries 1, 3, and 8), and use of non-recyclable catalyst (Table 6, entries 1–7). As shown in Table 6, it is clear that the current procedure is the use of a cheap, green, simple work-up procedure, high yields of products, and less time-consuming for the azidolysis of epoxides.

Comparison of azidolysis of some epoxides with different catalysts.

| Entry | Catalyst/solvent/temperature | Time (min) | Yield (%)c | Ref. |

| 1 | LiBF4/t-BuOH/Reflux | 70 | 95 | [27] |

| 2 | (TBA)4PFeW11O39·3H2O/CH3CN:H2O/80 °C | 4.5 h | 94 | [28] |

| 3 | NaN3/NH4Cl/MeOHH2O, reflux | 5 h | 90 | [33] |

| 4 | NaN3/Mg(ClO4)2/CH3CN, 80 °C | 2 h | 78 | [33] |

| 5 | NaN3/LiClO4/CH3CN, 80 °C | 5 h | 92 | [33] |

| 6 | 3D-network polymer/water/80 °C | 1.5 h | 89 | [42] |

| 7 | PTCa/water/80 °C/r.t. | 12h | 94 | [50] |

| 8 | SiO2-PEG-ImBr/water/reflux | 60 | 98 | [51] |

| 9 | Sulfuric acid/water/90 °C | 60 | 98 | [52] |

| 10 | MPTCb/water | 30 | 85 | [53] |

| 11 | [Cmmim]Br/solvent-free/60 °C | 15 | 96 | — |

| 12 | [Cmmim]BF4/solvent-free/60 °C | 15 | 95 | — |

a Poly[N-(2-aminoethyl)acrylamido]-trimethyl ammonium iodide.

b a, a′, a″-N-Hexakis(triethylammo-niummethylene chloride)-melamine as a multi site phase transfer.

c Yield of isolated products.

4 Conclusion

In conclusion, an efficient and new catalytic system is introduced for the regioselective preparation of 1,2-azidoalcohols from some epoxides with sodium azide under solvent free conditions at 60 °C mediated by a new natural-based acetic acid functionalized imidazolium salt [Cmmim]BF4 or [Cmmim]Br as an environmentally benign and reusable catalyst. The recovery of the catalyst, high regioselectivity, high conversions, mild reaction conditions, good to excellent product yields, being an environmentally friendly alternative, clean reaction profiles, and short reaction time make this catalytic system an alternative method for scaled-up synthetic purposes.

Acknowledgements

The authors wish to thank the Islamic Azad University Ilam for financial support to carry out this research. We also thank Dr. Rahimeh Hajinasiri for her assistance.