1. Introduction

Biomass is one of the oldest energy sources available on earth. Biomass has a major share in future energy supply of the world, it may partially subside the fossil dependency [1]. Due to its sustainability and environment friendly nature, the biomass is nowadays used in different applications such as energy production and biomaterials synthesis [2, 3, 4]. Currently, biomass has 14% share in world’s primary energy reserves [5]. Around 62% population of Pakistan resides in rural areas and uses solid biomass fuel as a primary source for cooking and heating in traditional cook stoves (TCS) [6]. The traditional use of biomass for cooking and heating in rural areas of Pakistan is inefficient and results in various environmental and health problems [7]. The rural areas of Pakistan such as Tharparkar region uses solid biomass fuel such as firewood, crop waste and animal dung for cooking and heating purposes. However, the combustion of solid biomass fuel in enclosed spaces results in indoor air pollution. Additionally, the combustion of solid biomass also emits particulate matter (PM), which causes pneumonia, stroke, heart disease, chronic obstructive pulmonary disease, and lung cancer [8]. Around 1.6 million people died prematurely in 2017 as a result of indoor air pollution, accounting 3% of global deaths [9, 10].

The cookstove design significantly affects the cookstoves’ performance and fuel consumption rate. The cookstoves’ designs were modified from time to time and improved with technological advancement such as by improving the design of stove and by performing mathematical modelling. Some authors categorized cookstoves i.e., as traditional cookstoves, improved cookstoves (ICS), advanced biomass cookstoves and effective improved cookstoves [11]. Traditional cookstoves (TCS) are commonly available in three types such as three-stone fire, mud stove and traditional coal/charcoal stoves. These traditional cookstoves are inefficient, have high fuel consumption, longer cooking time and high pollutant emissions. ICS are actually TCS-modified traditional stoves having closed combustion chambers with chimneys. ICS includes Magan Chulha generally found in India [12], Envirofit stove, Ugastove, Top-lit-updraft (TLUD) stove, Plancha stove, Patsari stove and Centrafricain stove [11]. All these ICS produce less harmful emissions, consume less fuel and reduce the cooking time as compared to traditional ones [13, 14, 15]. In addition, improved cookstove not only mitigates the greenhouse gas (GHG) and particulate matter (PM) emissions but also reduce the financial burden on a household by improving the fuel consumption [16]. Advanced cookstoves are designed at high standards, considering safety, efficiency, emission, and durability due to which these stoves have high cost and are unreachable for rural people. Improved cookstoves are advanced cookstoves design with scientific principles as well as technology and are user friendly [17].

The TCS have an efficiency of about 9 to 13% [18]. Ergo, to mitigate the environmental and health issues caused by the use of TCS, a lot of research is being carried out throughout the world on the development and dissemination of ICS which have lesser fuel consumption as well as harmful emissions [19]. In the last few decades, various types of ICS have been introduced with the modern scientific approach and are being disseminated in rural areas of developing countries including Pakistan [20]. Many studies have been performed on fuel conservation by ICS particularly in rural areas [21, 22]. The study performed by Harijan and Uqaili [23] estimated that replacing ICS with TCS in Pakistan can result in decreasing the demand for biomass fuel for cooking and heating purposes up to 50%. Furthermore, the dissemination of ICS in rural areas of the country can also reduce the deforestation rate. Still et al. [24] and Jetter and Kariher [25] discussed that ICS have lesser fuel consumption compared to TCS. The study concluded that the ICS not only reduces the fuel consumption, they could also potentially mitigate the health and climate change impacts due to the use of TCS [13, 26, 27, 28]. Bluffstone et al. adopted ICS for biomass cooking in Ethiopia. They reported that ICS reduced the cooking times by 18% over traditional stove in initial adoption of first 5 to 6 months. However, it further reduced by 7% in next 6 months [29].

ICS dissemination programs mostly are successful in rural areas where the main source of energy is fuel wood [30]. The performance of ICS can be evaluated by fuel efficiency [31, 32]. There are three distinct methods to evaluate the performance of cook-stoves namely; water boiling test (WBT), control cooking (CCT) and kitchen performance test (KPT). WBT is conducted in controlled environment. This method is mainly focused on simulation of cooking practices by water boiling hence does not present the actual cooking conditions. CCT is a field test capable of providing reliable results as compared to WBT. This method measures the fuel consumption and time of cooking. However, it may not predict the outcomes of uncontrolled usage of the cook-stoves in actual practice. KPT is a field base test that involves both qualitative survey and quantitative measurements. This method is quite useful than WBT and CCT since it involves pre-treatment surveys which assess the situation of households before dissemination of stoves and post treatment surveys which assess the impact of the cookstoves in the households [33, 34]. In order to evaluate the performance of TCS and ICS, a field based Kitchen Performance Test (KPT) is used, in which daily basis cooking is monitored and fuel consumption is assessed [13, 35, 36]. A study was conducted by Wallmo and Jacobson [35] for five days using KPT to analyze the fuel use of TCS and ICS. The results estimated that ICS could use 39% less fuel than TCS. Ochieng et al. compared the fuel consumption for TCS and ICS in rural areas of Kenya by conducting a KPT for two days. They concluded that TCS consumed more fuel than ICS [37].

Furthermore, a quantitative assessment using KPT was conducted of fuel use in rural households and the impact of stoves on household energy use with stove in developing countries like India, Nepal, and Peru. These studies concluded that ICS utilizes 27–66% less fuel as compared to TCS [38]. Agurto Adrianzén presented fuel consumption of ICS in Northern Peruvian Andes by using KPT analysis. The authors concluded that ICS could reduce fuel consumption by approximately 46% in the study area [39]. In addition, ICS could also significantly decrease IAP in kitchens by decreasing the particulate matter emissions up to 84% and CO emissions up to 99% [40]. Globally, a number of ICS type exits which can significantly reduce the harmful emission by 40–75%. Moreover, they also increase fuel efficiency by 30% and have the potential to reduce global warming up to 40–60% [41, 42].

Moreover, improved cookstoves (ICS) can be applied for the electricity production by retrofitting with low cost thermoelectric generator. Adding a thermoelectric generator is a viable solution to fulfil the basic needs such as light, phones and other electronic devices [43]. Several researchers have designed a prototype, an energy efficient cookstoves along with a thermoelectric power generator as an advancement in cookstoves [44, 45, 46, 47, 48, 49, 50, 51].

From the above literature, it can be inferred that the use of ICS has several benefits over TCS especially in rural areas of Pakistan in Tharparkar district where there is no gas supply. The people in Tharparkar mainly rely on combustion of fuel wood using TCS for their cooking heating purpose. Previous studies have shown that TCS consumed more fuel wood than ICS and due to increase in the cost of fuel wood along with various socio-economic problems, people in Tharparkar district are facing severe social and economical problems. Therefore, there is an urgent need for improved cooking technology which can be economical for rural population, consumes less fuel and could be environment friendly.

This study aims to identify the fuel wood potential and consumption in rural areas of Tharparkar district. The ICS and TCS cookstoves were used to estimate the fuel wood consumption. The characteristics of fuel wood were determined by ASTM method. A KPT was used to measure the reduction in fuel consumption and reduction in CO2 emissions.

2. Material and methods

2.1. Study design and sample size

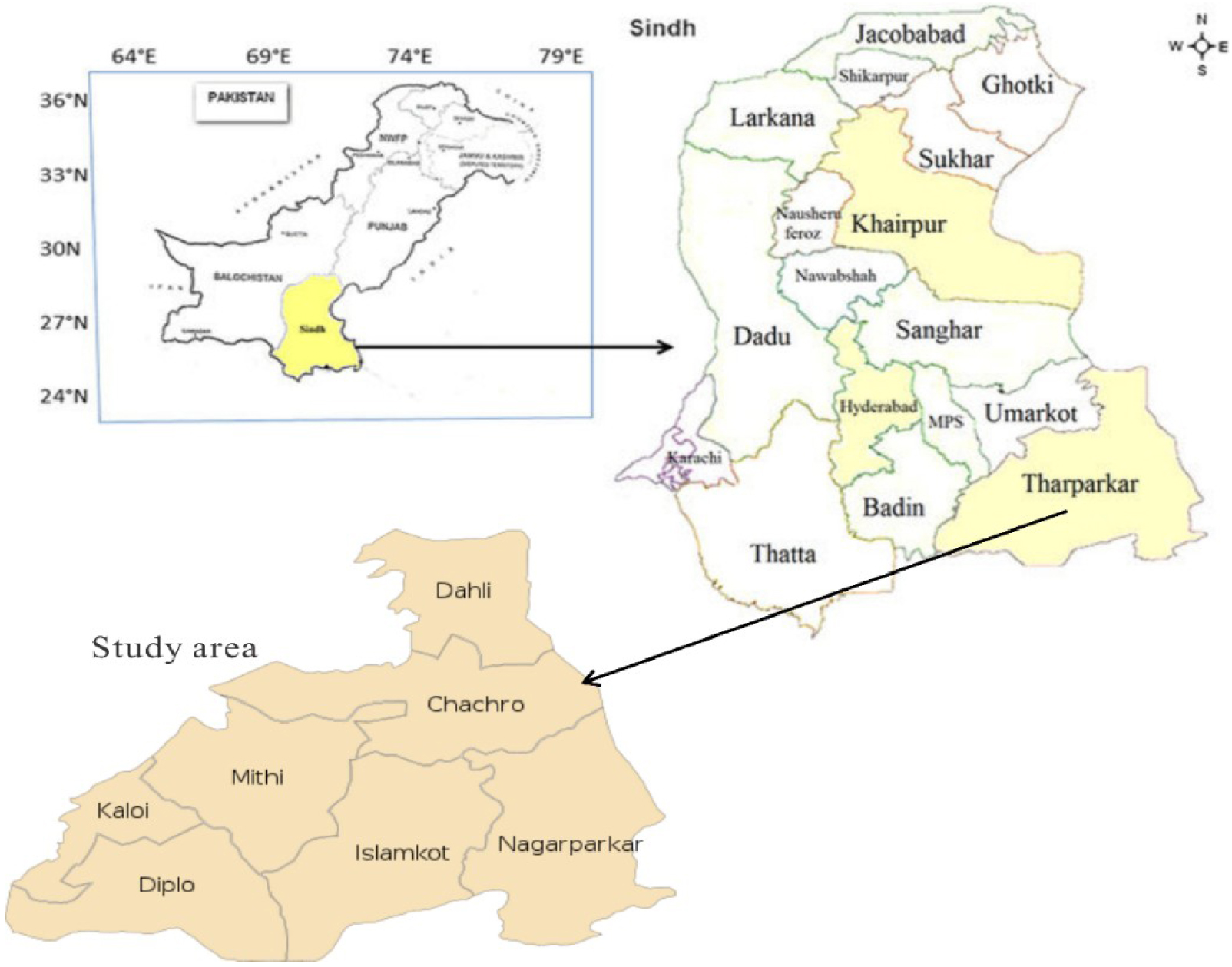

The study was conducted in the Tharparkar district of Pakistan located in the southern part of the country as shown in Figure 1. Tharparkar district was selected since it is to one of the highly remote areas of Pakistan.

Map of Tharparkar district Pakistan focusing study area.

The entire population in the district relies on biomass fuel (i.e. fuel wood) for their basic cooking and heating energy requirements. Tharparkar district is subdivided into 7 administrative talukas, Mithi, Diplo, Islamkot, Chachro, Dahli, Nagarparkar and Kaloi. For this study, Diplo taluka was selected. Diplo is located at 24° 35′′ N 69° 35′′ E, 40 km away from district headquarter Mithi, having an area of 2673 km2 and an estimated population of 147,978 in 2017 [52]. The selected location is remote and rural having an average household size of 5.6 [53]. The households use fuel wood mainly from Propis glaandulosa which is the most common tree found in the study area. Majority of the population in the study area burns fuel wood for their energy needs using TCS. TCS and ICS used in the current study are shown in Figures 2 and 3, respectively.

Traditional Cook Stove (TCS) used in Tharparkar district, Pakistan.

Improved Cook Stove (TCS) used in Tharparkar district, Pakistan.

In Figure 3, stoves’ emission on the wall of the kitchen represents incomplete combustion due to the usage of TCS for cooking for several years. The use of forced draft ICS can improve combustion by maintaining the required air to fuel ratio. However, the habitants are poor and cannot afford to have force draft ICS that requires electricity or batteries for their operation. Therefore, this study focuses on natural draft ICS only, as they are easy to operate and do not require any additional cost for operation. Although, the gaseous emissions from natural draft ICS are higher than forced draft ICS, they are still lower as compared to TCS due to exhaust chimney.

Figure 4 shows KPT survey approach that was used in present study. The KPT was conducted in two stages: the first stage was conducted before the distribution of selected ICS and at second stage survey was conducted when they ICS were distributed in selected community households. During both stages of the study, a survey covered the consumption of fuel wood by ICS and TCS. The second stage of the survey was conducted after a month and the selected ICS has similar physical properties that were used in the literature [37]. The KPT was performed during 3 months from December 2016 to February 2017. During this period, the baseline information of study households, qualitative features of the stoves and fuel use, number of family members was obtained using interviewer administrated semi-structured questionnaires. In order to find the fuel consumption of TCS and ICS, the testing was carried out by finding the daily measurements as families use the TCS for 3–7 days, followed by daily measurements of the same families using selected ICS for the same period of time. This kind of test makes an evaluation of the family’s daily fuel consumption with the traditional stove and with the improved stove.

2.2. Fuel characterization

The main parameters affecting the wood fuel performance are its chemical composition, heating value and the proximate analysis, i.e. moisture volatile matter, fixed carbon and ash contents. The moisture content is different in different parts of the tree and it affects the energy content in the wood fuel [54]. Higher the moisture content, lower the heating value [55]. Ash content is the core parameter in fuel characteristics that directly affect the heating value. Large ash content in the tree or plant part makes it less desirable as fuel [56]. The fuel characteristics are determined through proximate and ultimate analyses. The proximate, ultimate analysis and gross caloric value of the fuel wood obtained from Propis glandulosa was performed as per the American Society for Testing and Materials (ASTM) standards ASTM E870-82 (2006).

2.3. Fuel use measurement

The fuel use measurement is actually the extent to which how fuel wood is consumed per day for cooking, and heating. The fuel wood consumption is estimated by monitoring the quantity of fuel used before and after cooking and heating. The estimation of per capita fuel wood consumption is presented as “standard adult equivalent” (SAE) per day. The SAE is utilized in the KPT to normalize the caloric energy requirements by gender and age with the following weights: child 0–14 years = 0.5; female over 14 years = 0.8; male 15–59 years = 1; and male over 59 years = 0.8 [57]. In this study, three days of repeated fuel use measurement in a relatively large sample size KPT is performed. The participants prepared food with three batches of fuel enough for 3 days of cooking, based on their typical daily basis requirements. The weight of fuel for each batch was weighed on the calibrated digital scale (Model SF-400A, ranges 0.1–10 kg) before starting the experiment at the start of the day. On the second and third day of the tests, the fuel that remained from the first day was weighed and the difference is recorded as the day’s fuel consumption.

2.4. Fuel wood potential

The major sources of fuel wood in the Tharparkar district are forest and agricultural land. Tharparkar has around 93 thousand hectares of forest cover representing 7% of the total land area of the district. Agriculture land cover is around 1014 thousand hectares of representing 50% of the total land area of the district [58]. The production of agricultural crops completely depends on the rain during the monsoon season and these are only cultivated once in a year. Therefore, the main source of fuel for local inhabitants is only fuel wood for their cooking and heating. This fuel is usually obtained by cutting the local trees in the vicinity of the region. The potential of fuel wood production from the forest in the Tharparkar district can be estimated using Equation (1) [59] as:

| (1) |

2.5. Emissions measurement

The share of ICS in diminishing CO2 emission was evaluated by the amount of fuel wood saving as per the SAE of the households using ICS. The estimation of CO2 reduction was carried out by using the Equation (2) as per clean development mechanism and the United Nation’s framework of Convention on Climate Change which is given as [60]:

| (2) |

ERy = Emission reduction during the year in tons of carbon dioxide equivalent (tCO2e)

By⋅Savings = Annual fuel wood saved per ICS in tons

fNRBY = Fraction of non-renewable biomass

NCVbiomass = Net calorific value of the non-renewable biomass

EFfuel wood = Emission factor of fuel wood.

The values of the parameters used for estimating CO2 reduction by ICS are presented in Table 4. Carbon Monoxide CO is considered indirect greenhouse gas due to its close coupling to atmospheric methane [61]. Therefore, it is necessary to measure the CO emission for the evaluation of biomass improved cookstoves. In the present study, the CO emission is measured by a portable CO analyser (KANE-Model 100-1) and the concentration of particulate matter PM2.5 is measured by Aerosol Monitor (Model DustTrak 8530, TSI Inc.). Presented results are the average of the 3 repetitions of the performance tests.

3. Results and discussion

Tharparkar district is one of the arid region of the Pakistan and its regional population is completely contingent on fuel wood for their basic needs. The major source of fuel wood is natural forest and agrarian land. The natural forest together with the agricultural land could generate around 242 thousand tonnes of fuel wood per year in the district Tharparkar as given in Table 1. However, besides natural forests and agricultural land, there are also few other major sources of wood supply like other wooded lands, plantations beside homes and scrap wood generated during the construction activities. These sources of fuel wood are not counted in this estimation because no reliable data source was available. The population of Tharparkar is around 1.65 million and almost 98% of this population uses fuel wood as a source of energy to meet their daily cooking and heating energy requirements.

Fuel wood production of Tharparkar district

| Fuel wood source | Area (“000” ha) | Fuel wood productivity (tonne/ha/year) | Availability factor (%) | Fuel wood production (thousand tonnes) |

|---|---|---|---|---|

| Forest | 93 | 1 | 80 | 74 |

| Agricultural land | 241 | 0.7 | 80 | 168 |

| Total | 242 |

Considering 0.87 kg of fuel wood consumption per person per day the annual fuel wood consumption of the Tharparkar is estimated to 538 thousand tonnes per year. The consumption of wood in the Tharparkar is almost 1.45 times its fuel wood potential. This higher and inefficient consumption of the fuel wood, as well as the lack of availability of modern energy sources for the daily energy needs, are the main reason for the deforestation and degradation of the environment in the district.

The characteristics of biomass fuel wood are determined and given in Tables 2 and 3. The carbon C and oxygen O content percentage are found within the standard range of about 49.1% and 42.4%, respectively. One advantage of biomass fuel wood over fossil fuel is its very low content of sulphur which was found to be around 0.02%. Volatile matter in fuel wood was 74.47%. The low moisture and ash contents indicated the positive impact on the heating value of biomass fuel wood. The moisture and ash content in the fuel wood were 2.85% and 1.78%, respectively. The low moisture content can be due to fuel type. Thus, the higher heating value was calculated as 17.8 MJ/kg.

Ultimate analysis of the fuel wood

| C (%) | H (%) | N (%) | S (%) | O (%) |

|---|---|---|---|---|

| 49.1 | 6.1 | 0.2 | 0.02 | 42.4 |

Proximate analysis of the fuel wood

| Moisture (%) | Ash (%) | Volatile matter (%) | Fixed carbon (%) | HHV (MJ/kg) |

|---|---|---|---|---|

| 2.85 | 1.78 | 74.47 | 14.90 | 17.8 |

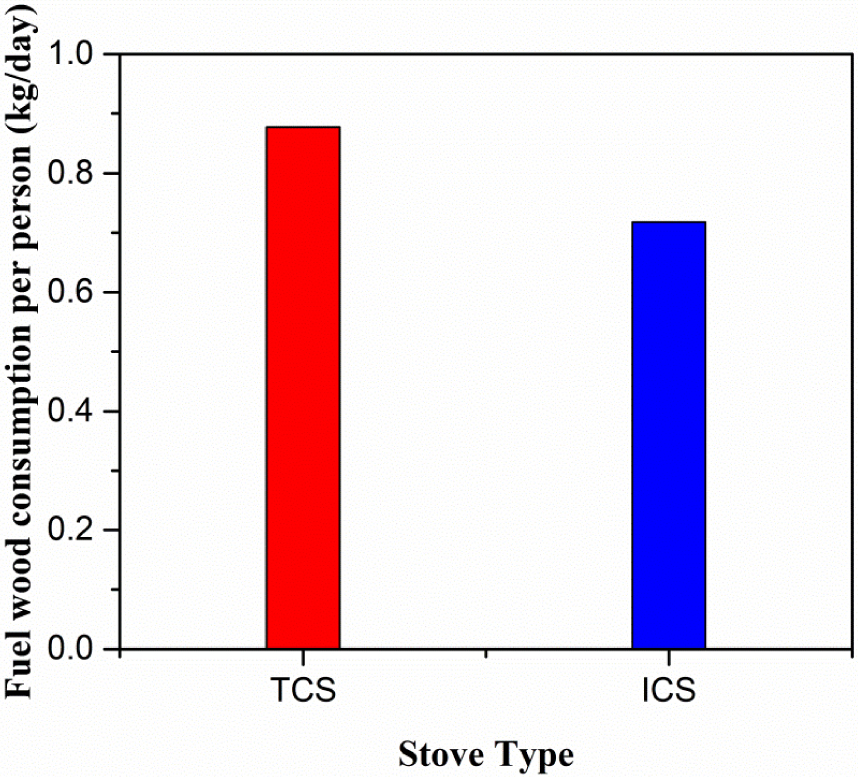

The fuel wood consumption was estimated as per kitchen performance test KPT method by monitoring fuel consumption before and after cooking and heating for the TCS and ICS. For the first day of the test, the fuel consumption of TCS was about 0.880 kg of dry wood with the standard deviation of 0.148, per person per day, while for the second and third day fuel consumption was around 0.865 kg with SD of 0.1126 and 0.891 kg with SD of 0.148 per person per day respectively. Consumption of fuel wood for ICS was about 0.749 kg of dry wood with SD of 0.129 on the first day, 0.705 kg with SD of 0.107 on the second day, and 0.7007 kg with SD of 0.099 per person per day on the third day of the KPT monitoring. A substantial reduction in fuel wood consumption was observed with ICS as compared to TCS.

Figure 5 represents the fuel wood consumption of TCS and ICS. The KPT results show that the TCS consumed fuel wood averagely of about 0.878 kg per day per person and ICS consumed averagely of about 0.718 kg per day per person. The consumption of fuel wood is apparently reduced from 0.878 kg per day to 0.718 kg per day per person when ICS has been successfully installed instead of TCS. Thus, ICS uses almost 0.16 kg/person/day less fuel wood as compared to TCS. Thus, the KPT analysis reveals that there is a significant reduction in fuel consumption when the households have switched to ICS. It is observed that change in fuel use was related to the kind of stove used, with ICS consuming less fuel as compared to the TCS. There have been very few studies presenting household fuel use by conducting KPT. While the studies have shown that a significant amount of fuel can be saved by changing TCS with different types of ICS [19, 25].

Comparison of fuel wood consumption with TCS and ICS.

The performance of cookstove can be compared quantitatively using stove performance index (𝜂SPI), which is defined as 𝜂SPI = (Fs − Fc)∕Fs, where Fc is stove fuel consumption in kg per person per day and Fs is amount of initial wet wood fuel supplied in kg per day which is 12 kg.

The higher values of the stove performance index indicate less fuel consumption and better performance by the cookstove. Figure 6 shows the cookstove performance index for TCS and ICS, respectively. It can be observed from Figure 6 that the values of performance index for TCS and ICS are 0.926 and 0.94 per person per day, respectively. It is implying that the ICS consumed ≈2% less fuel per person per day as compared to TCS. Considering the household size of 4.1 (According to SAEs), the ICS can consume approximately 6–8% less fuel per house as compared to TCS. Moreover, the performance of the ICS can further be enhanced by adapting new scientific approach, designing methods and suitable materials.

Cookstove performance index.

ICS dissemination programs has an important role in the implementation of the policies and programs that aims to reduce the social and environmental problems related to the use of fuel wood in traditional inefficient cook stoves in rural areas of developing countries like Tharparkar district of Pakistan. Thus, the ICS can be successfully disseminated and implemented in different rural regions of the Tharparkar district of Pakistan. Moreover, the current study has also received positive response from the local inhabitants after the dissemination of ICS. Their positive response implies that the ICS not only reduce the fuel consumption but also improve the indoor air quality.

It is very difficult to minimize random errors in a field-based test during the measurement of fuel wood consumption. However, careful consideration was given to the techniques to decrease the errors by following the testing protocols of KPT (for example the test supervisors were from the test area and were given proper training; all the instruments and scales used in the study were calibrated). The participants of the test were also given the training to follow their daily routine cooking style during the test tenure. The test supervisors visited the test participants from time to time to make sure they are following the test protocols correctly. It was also observed in this study that the factors like rainy weather, guests, unattended stove, and cooking by inexperienced cook such as children may also cause some errors in the results. However, these factors are unintentional and cannot always be avoided.

Forests are the main source of fuel wood around the world. The extensive use of fuel wood, growth in the population, agricultural land and poverty are the major threats to forests. The time spent collecting fuel wood has a significant social and economic impact on the life of women and children who spent hours collecting fuel wood. Hence, in this scenario, the use of ICS in the areas where fuel wood is the main source of energy can help in partial reduction of deforestation as well as it will improve the socio-economic conditions of the people living there. Additionally, the use of ICS can also be helpful in climate change mitigation and the reduction in indoor pollution due to the reduction in fuel consumption and reduction of carbon emissions. Especially for Pakistan, who is already suffering from deforestation and has one of the highest deforestation rates in the world.

Table 4 present the estimated the CO2 reduction by the use of the ICS. The CO2 reduction was estimated by applying Equation (2). The CO2 reduction due to the use of ICS was estimated as 0.063 tons equivalent per ICS per person per year. This estimation incorporates the average annual fuel wood saving by ICS of around 58.4 kg per person. Hence, with the normal family size (measured in SAEs) of about 4.1, ICS could decrease 0.259 tons of CO2 equivalent per ICS user.

Values of parameters used for estimating CO2 reduction

| Parameter | Values | Reference |

|---|---|---|

| Annual fuel wood saved per ICS | From KPT | |

| The net calorific value of fuel wood (wet basis) | 15 MJ/kg | [62] |

| Emission factor of fuel wood | 81.6 (CO2/T) | [60] |

| Fraction of non-renewable biomass | 88% | [62] |

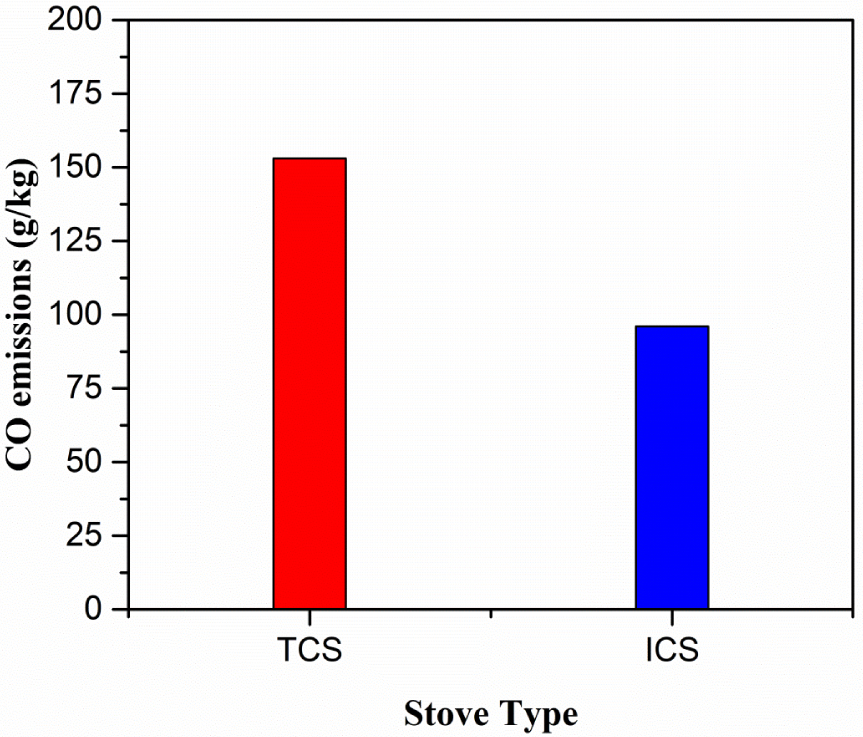

Moreover, Figures 7 and 8 show the CO and PM2.5 emissions for TCS and ICS. The CO emission were measured by a portable CO emission analyser. The emissions were carefully monitored and recorded throughout all three days of the field test. The measured values were repeated and averaged for a single value. The CO and PM2.5 emissions for TCS were recorded as 153 g/kg and 8.9 g/kg, respectively. Similarly, the CO and PM2.5 emissions for ICS were found to be around 96 g/kg (SD = 3) and 5.7 g/kg (0.7) respectively.

CO emissions for TCS and ICS.

PM2.5 emission for TCS and ICS.

Hence, the results in the current work are in good agreement with the study conducted by Roden et al. [63]. ICS significantly reduce the CO emission factor by 37.25%. The reduction in CO and PM2.5 emissions for ICS can be attributed to the improved design and operation of ICS that promote proper combustion of the fuel wood. Thus, ICS not only reduces fuel consumption, but it can also significantly reduce carbon and PM emissions.

4. Conclusions

The fuel wood consumption of cookstove is measured by employing a field-based test (KPT) in the Tharparkar region of the Pakistan. The KPT analysis were carried out for the TCS and ICS. The CO and PM2.5 emission analyses were also carried out. The following conclusion are drawn from the present study;

- The fuel consumption estimation presented in this study shows that in rural Pakistan the use of ICS can lead to a significant reduction in fuel consumption from 0.878 kg per person per day to 0.718 kg per person per day and can also reduce CO2 emissions by 0.259 tons per ICS user annually.

- The performance index represents that the ICS consumes approximately 6% less fuel as compared to TCS.

- The CO emission and PM2.5 concentration reduced nearly 37.25% and 36%, respectively with the intervention of ICS over TCS.

- The dissemination of ICS in the rural areas of Pakistan as well in the other developing countries can offer a short term solution to the deforestation and physical burden on poor people due to the collection of fuel wood. Thus, the ICS can be disseminated successfully in the Tharparkar district of the Pakistan.

5. Recommendations

- KPT is a field-based test conducted in an uncontrolled environment. The result of the test may vary from area to area or community to community. For further understanding of the fuel consumption by ICS, the results obtained from KPT can be compared with the results obtained from a controlled environment based test such as water boiling test (WBT) and control cooking test (CCT).

- Further estimation of fuel consumption by ICS can be performed across a range of stove technologies and fuels such as wheat straw, wood pellets, torrified pellets, and dung.

- The economic, environmental and social impacts of ICS also need further investigation.

Conflicts of interest

No potential conflict of interest was reported by the authors.

Funding

This study was not funded by any funding agency.

CC-BY 4.0

CC-BY 4.0