1 Introduction

Catalysis was established as the 9th of the twelve principles of green chemistry and is sometimes referred to as the “foundational pillar” of green chemistry [1]. Among many catalysts, Lewis acids play a central role. Current interest in green chemistry promotes the development of heterogeneous catalysis, including the use of supported Lewis acid catalysts. The potential of such systems brings numerous advantages, such as protection of moisture-sensitive Lewis acids from hydrolysis through their dispersion on a support, easier manipulation, and avoidance of deactivation by hydrolysis. Furthermore, chemo-, regio-, and stereoselectivity can be optimized, work-up is based on simple filtration, wastes are minimized and Lewis acid catalyst recycling becomes possible [2]. Additionally, modern chemistry requires chemical processes designed to reduce waste production, facilitate efficient reuse and recycling, and use of starting material derived from renewable resources or from abundant wastes [3,4].

In line with the aforementioned new trends in organic chemistry, here we report on the preparation and usage of supported Lewis acid catalyst derived from non-conventional biomass, i.e. metal-hyperaccumulating species, that we named “ecological catalysts”. Metal-hyperaccumulating plants, or metallophytes, extract trace metals (TM) from soil and concentrate them in their shoots. Exploring the utility of these plants led to the development of phytoextraction techniques that represent an opportunity to remove TM from contaminated soils, e.g., contaminated mine sites, which in turn represent a major environmental problem worldwide. Nowadays, the approach using plants to clean up the environment is cost-effective, achievable on a large-scale, and has a good public acceptance. The main disadvantage, however, is the lack of real economic opportunities [5–8]. Herein, we demonstrated that metallophytes could be the basis of a novel, plant-inspired, metallo-catalytic platform with synthetic potential in one of the most important processes in organic chemistry, namely the Diels–Alder reaction. In the presented study we used the two best zinc hyperaccumulating plants, Noccaea caerulescens and Anthyllis vulneraria. Both are able to concentrate about 120,000 ppm of ZnII in calcined shoots [9].

2 Results and discussion

2.1 Preparation and characterisation of the ecological catalysts

The ecological catalysts were prepared by thermal treatment of leaves at 400 °C, followed by the addition of HCl (1 M) and the concentration of the solution, which led to an unusual mixture of metallic chlorides and oxides [9–14]. The potential of zinc hyperaccumulating plants for ecological catalysis was based on the total mineral composition of contaminated biomass. The presence of ZnII, CdII and PbII results from the trace metals (TM) hyperaccumulation ability of metallophyte plants. Additionally, NaI, KI, CaII, MgII, FeIII were also present as they are essential for plant growth. X-ray fluorescence (XRF) was used to determine the exact chemical composition of the obtained plant extract (Table 1).

Composition of the obtained plant extract.

| Mass percent composition | Na | K | Mg | Ca | Fe | Zn | Cd | Al | Pb | O | Cl |

| A. vulneraria and N. caerulescens crude extracts | 1.72 | 5.72 | 1.60 | 10.30 | 2.75 | 6.75 | 0.19 | 1.50 | 0.44 | 15.97 | 42.27 |

XRF data were additionally confirmed by inductively coupled plasma mass spectroscopy (ICP–MS). The extract contained high amounts of transition metals: 6.75% of ZnII and 2.75% of FeIII, known to be powerful Lewis acids. A significant amount of CaII (10.30%) was also noted. The results presented in Table 1 confirmed the exceptional capacity of Noccaea caerulescens and Anthyllis vulneraria for the hyperaccumulation of Zn. It has to be noted that, using ion-exchange resin Amberlite IRA 400, it was possible to separate the metallic species and obtain fractions enriched in ZnII and CaII [15]. In this study, however, only crude extracts were employed.

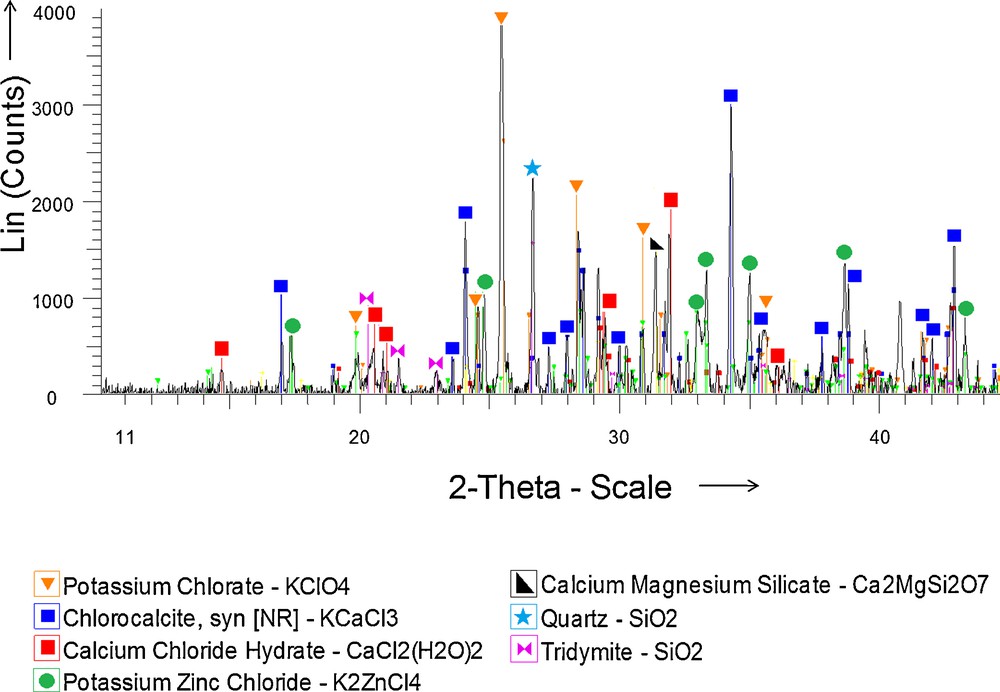

Subsequently, the resulting plant extract was deposited on montmorillonite K10 as a conventional support. The methodology was based on a co-grinding; montmorillonite K10 was placed in a porcelain mortar and air-dried crude extract was then added and mixed with montmorillonite K10 using a pestle to obtain a homogeneous powder [16]. The supported ecological catalyst was characterized by XRD (Fig. 1). As shown in Table 2, K2ZnCl4 was the sole observed zinc chloride; it is a masked form of ZnCl2 [15].

X-ray diffraction (XRD) pattern of our supported ecological catalyst (colour online).

X-ray diffraction (XRD) pattern of our supported ecological catalyst.

| Fraction | Mineral | Formula (simplified) |

| Supported ecological catalyst on montmorillonite K 10 | Chlorocalcite, syn | KCaCl3 |

| Potassium zinc tetrachloride | K2ZnCl4 | |

| Potassium perchlorate | KClO4 | |

| Calcium chloride hydrate | CaCl2(H2O)2 | |

| Calcium magnesium silicate | Ca2MgSi2O7 | |

| Quartz | SiO2 | |

| Tridymite | SiO2 |

2.2 Determination of the Lewis acidity of the crude ecological catalyst

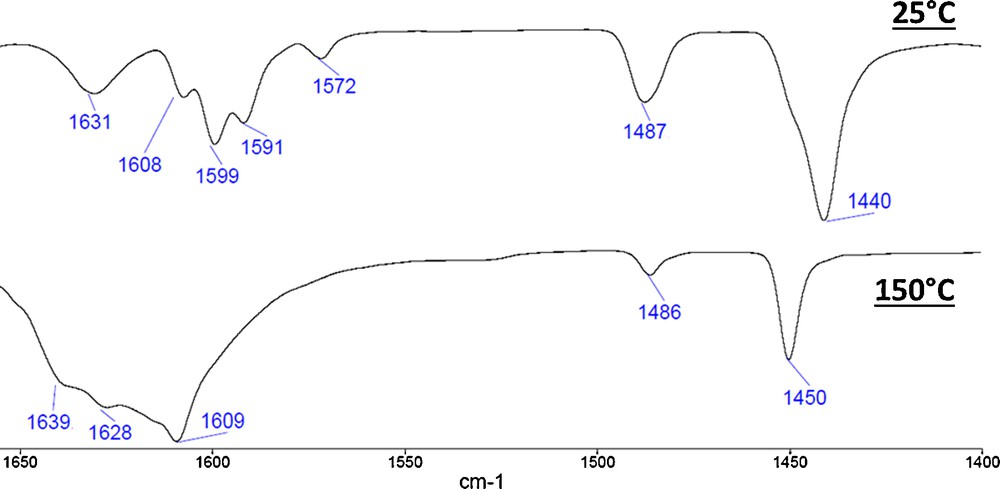

In order to determine the Lewis acidity of the ecological catalyst, infrared spectra of pyridine adsorbed on crude fraction were recorded at 25 °C and 150 °C in order to distinguish frequencies of physisorbed pyridine from frequencies of pyridine coordinated to Lewis sites (Fig. 2). Pyridine is widely used as a probe molecule for the determination of the Lewis acidity of solid acids, by monitoring the bands in the range of 1400–1650 cm−1 arising from its ring vibration modes [17,18].

IR spectra of adsorbed pyridine on a crude extract taken following brief outgassing at the indicated temperatures.

As shown in Fig. 2, a band at 1440 cm−1 observed at 25 °C disappeared after outgassing at 150 °C, and thus could be attributed to physisorbed, weakly bonded, pyridine [17]. In the same range, a band at 1450 cm−1 was observed at 150 °C. This band is characteristic of pyridine, which is still strongly bonded at this temperature by coordination to Lewis acid sites [17]. This was the first indication of the extract Lewis acidity. In turn, the band intensity at 1486–1487 cm−1 could be attributed to physisorbed pyridine, as the intensity was strongly reduced after heating.

Furthermore, the band at 1599 cm−1 observed at 25 °C, which disappeared at 150 °C, is characteristic of hydrogen-bonded pyridine [17]. Additionally, several bands were observed in the range of 1600–1640 cm−1 with small frequency variations, depending on outgassing temperature (1608 and 1631 cm−1 at 25 °C; 1609, 1628 and 1639 cm−1 at 150 °C). The continued existence of bands in this range, in spite of heating at elevated temperature, indicates the presence of strongly bonded pyridine. In previous studies, these bands were attributed to pyridine coordinated to Lewis acid sites. The occurrence of these bands at different frequencies in this range may account for the involvement of different types of Lewis acid sites [18].

2.3 Application of the supported ecological catalyst in the Diels–Alder reaction

The Diels–Alder reaction is one of the most popular transformations for organic chemists to efficiently generate molecular complexity. Since its discovery in 1928 by Diels and Alder [19], this pericyclic reaction involving a conjugated diene and a dienophile has been used for the diastereo- and regioselective generation of six-membered rings with up to four stereogenic centres in a single step. The Diels–Alder reaction has opened the way to the synthesis of a plethora of organic substances with elaborated structures, thus underlining its power for the rapid generation of molecular complexity [20–22]. This transformation is universally acknowledged for the rapid, atom-economical build-up of complex structures of defined geometry with minimal waste. These criteria fulfil the requirements of a scalable chemical process; thus application of this transformation in chemical industry is a feasible enterprise [23–25].

Inspired by the previous works on the successful application of clays [26–28] and zeolites [29] as catalysts for the Diels–Alder reaction, we decided to use our K10-supported ecological catalyst for that transformation. Initially, the reaction of 3-buten-2-one with 2,3-dimethyl-1,3-butadiene, as model substrates, was investigated. Reactions were carried out in toluene at 110 °C for 4 h (Table 3).

Effect of the nature of the Lewis acid catalyst on the model Diels–Alder reaction of 3-buten-2-one with 2,3-dimethyl-1,3-butadiene.

| Entry | Catalysta | Yield [%]b |

| 1 | K10-supported ecological catalyst (0.1 equiv. Zn) | 100 |

| 2 | K10 | 44 |

| 3 | ZnCl2 (0.1 equiv. Zn) | 67 |

| 4 | Recycled K10-supported ecological catalyst (0.1 equiv. Zn)c | 98 |

| 5 | No catalyst | 6 |

a Reaction conditions: toluene, 110 °C, 4 h.

b Yield determined by GC-MS.

c Catalyst recycled one time.

The screening of the nature of the Lewis acid catalyst used revealed a pronounced effect on the reaction yield. To our satisfaction, it was found that the use of our K10-supported ecological catalyst leads to the desired product in quantitative yield (Table 3, entry 1), whereas the application of commercially available ZnCl2 gives only 67% of the desired product (Table 3, entry 3). Knowing that the montmorillonite K10 can catalyse the Diels–Alder reaction [28], we have performed the model reaction only in the presence of this catalyst; however, a yield of 44% only of the desired product was obtained (Table 3, entry 2). The reaction carried out in the absence of any catalyst resulted in the formation of only trace amounts of the desired product (Table 3, entry 5). Importantly, we were able to recycle and reuse our ecological catalyst (Table 3, entry 4). After filtration of the K10-supported ecological catalyst, washing with toluene (3 × 20 mL) and Et2O (3 × 20 mL), drying at 150 °C for 5 h, the catalyst was reused and did not show significant loss in activity (Table 3, entry 4).

Subsequently, a selected spectrum of dienes and dienophiles was examined to test the scope and limitations of the K10-supported ecological catalyst (Table 4). When cyclopentadiene was used as a substrate, the reaction proceeded well already at low temperatures and furnished the desired products with very good yields in short times (Table 4, entries 2, 4, 6). It has to be noted that very good endo/exo reports were obtained (Table 4, entries 4, 6). When myrcene was used as a dienophile, very good selectivity of the Diels–Alder reaction was observed (Table 4, entry 7). Importantly, under the same reaction conditions experiments performed with the use of montmorillonite K10 resulted in the formation of the desired products in much lower yields (Table 4, entries 3, 5).

Scope of the Diels–Alder reaction catalysed by the K10-supported ecological catalyst.

| Entry | Diene | Dienophile | Product | Catalyst | Solvent | T [°C] | t [h] | Yield [%]a | endo/exo |

| 1 | K10-supported ecological catalyst (0.1 equiv Zn) | Toluene | 110 | 4 | 100 | – | |||

| 2 | K10-supported ecological catalyst (0.1 equiv Zn) | Toluene | 5 | 1 | 93 | – | |||

| 3 | K10 only | Toluene | 5 | 1 | 34 | – | |||

| 4 | K10-supported ecological catalyst (0.1 equiv Zn) | Toluene | 25 | 0.25 | 91 | 95/5 | |||

| 5 | K10 only | Toluene | 25 | 0.25 | 33 | 95/5 | |||

| 6 | K10-supported ecological catalyst (0.1 equiv Zn) | CH2Cl2 | 5 | 4 | 98 | 91/9 | |||

| 7 | “1,4 adduct”+ “1,3 adduct” (1,4/1,3: 80/20) | K10-supported ecological catalyst (0.1 equiv Zn) | Toluene | 110 | 4 | 99 | – | ||

| 8 | de: 71%b | K10-supported ecological catalyst (0.1 equiv Zn) | Water | 60 | 1.5 | 92 | – | ||

| 9 | c | d | K10-supported ecological catalyst (0.1 equiv Zn) | Water | 25 | 6 | 84 | – |

a Yield determined by GC-MS.

b Determined by 1H NMR.

c Dienophile generated in situ, by mixing formaldehyde and ammonia.

d Isolated as hydrochloride.

Additionally, we discovered that the K10-supported ecological catalyst also catalyses the hetero Diels–Alder reaction (Table 4, entries 8, 9). Environmentally benign conditions of that reaction are worth mentioning; use of water as solvent and moderate reaction temperature and time. Importantly, very good diastereomeric excess (de) in the lactone, formed by rearrangement of the endo transient cycloadduct, has to be noted (Table 4, entry 8). Similar reaction catalysed by Cu(II) reported in the literature gave the lactone with de = 30% [30].

We have also performed the Diels–Alder reaction in an asymmetric fashion. The reaction of cyclopentadiene and dimenthyl fumarate is known to proceed with high stereoselectivity when strong Lewis acids are used at –78 °C, affording 6 in 99% de [31].

However, the search for efficient catalysts that can be used under softer conditions is still needed [32]. Encouraging results were obtained in asymmetric cycloaddition when our Zn-ecological catalyst was used (Scheme 1).

Asymmetric Diels–Alder reaction catalysed by our K10-supported ecological catalyst.

When coordinated to Lewis acids, the dimenthyl fumarate exists in the s-trans form predominantly, thus the two (–)-menthyl groups cover the re face of the molecule [31]. Therefore, the addition of cyclopentadiene affords mainly the product 6, obtained in 63/38 (S,S)/(R,R) ratio with the use of our Zn-ecological catalyst. It should be noted that this value is much higher than that obtained with commercial ZnCl2, reported to be only 52/48 [32].

3 Conclusions

In conclusion, we have prepared and characterised a novel supported Lewis acid catalyst issued from biomass of Zn hyperaccumulating plants Noccaea caerulescens and Anthyllis vulneraria. The catalytic activity of the catalyst was tested in the Diels–Alder reaction. The use of this eco-catalyst is featured with mild reaction conditions, simple operation, low catalyst loading, good substrate scope, excellent selectivity, and the possibility of its recovery and reuse. Further experimentation would be required in order to fully determine the potential of the new plant-based catalysts, but there is no doubt that they will continue to display very interesting properties for cutting-edge green chemistry. Additionally, the use of metal-hyperaccumulating plants as a source of metals for applications as catalysts in chemical processes presents an interest for the phytoremediation of mine sites contaminated with heavy metals.

4 Experimental part

4.1 Preparation of catalytic extracts from metallophyte species

Leaves were harvested before flowering, air-dried and crushed. The obtained solid (150 g) was calcinated at 400 °C for 5 h and the resulting powder (24 g) was added to 1-L of a solution of a 1 M HCl solution. The solution was heated at 60 °C and stirred for 2 h. The reaction mixture was filtered on celite. The resulting solutions, composed of different metal chlorides, were concentrated under vacuum. Dry residue was supported on montmorillonite K10 by co-grinding with mortar and pestle, at room temperature. The 2.0 g of montmorillonite K10 were mixed with the plant-derived Lewis acids (amount corresponding to 1.1 mmol of metal of interest/g of support). This mixture was activated at 100 °C for 15 min before use.

4.2 Characterization of catalytic extracts issued from metallophyte species

Chemical analysis of the plant extract samples after calcinations (400 °C for 3 h) was performed by X-ray fluorescence spectrometry (XRF) using a Bruker AXS S4 Explorer wavelength-dispersive spectrometer. The quantitative analysis of major and expected elements was performed on beaded samples for overcoming problems of particle size variation as well as mineralogy effects: the powdered sample is mixed with a Li2B4O7 flux with a flux/sample ratio equal to 8, heated in a crucible between 400 and 600 °C, then cast in a platinum dish to produce a homogeneous glass-like bead.

ICP–MS was used to confirm the composition of the various plant extracts obtained. ICP–MS analyses were performed using the metal analysis of the total dissolved solutes in water. The samples were acidified with nitric acid 2.5% and stirred for 30 min. The digestates were diluted to 0.005 g.L−1. Three blanks are recorded for each step of the digestion and dilution procedure on a HR-ICP–MS Thermo Scientific Element XR.

X-ray diffraction (XRD) data measurements on the samples dried at 110 °C for 2 h were performed by using a Bruker diffractometer (D8 advance, with a Cu Kα radiation λ = 1.54086 Å) equipped with a Lynxeyes detector.

FT-IR measurements were carried out using pyridine as a probe molecule. The samples were pressed into wafers (8 mg.cm−2) and activated in the IR cell under flowing air (1 cm3.s−1) at 400 °C for 10 h and then under vacuum (10−3 Pa) for 1 h. A PerkinElmer Spectrum 100 FT-IR spectrometer was used for recording the spectra. Excess gaseous pyridine was adsorbed, then the samples were degassed for 15 min at 25 °C (10−3 Pa), and a first spectrum was recorded. The samples were then degassed for 15 min at 150 °C (10−3 Pa) to eliminate the physisorbed pyridine, and a second spectrum was recorded.

4.3 Representative procedure for the Diels–Alder reaction

A round-bottom flask equipped with a condenser was charged with the catalyst derived from biomass (32 mg, quantity corresponding to 0,01 mmol of Zn, 0,10 equiv, according to ICP–MS and XRF analysis), 3-buten-2-one (7 mg, 0.1 mmol) and 2,3-dimethyl-1,3-butadiene (8.2 mg, 0.1 mmol) and 2 mL of toluene. The flask was placed in an oil bath and heated at 110 °C for 4 h. After that time, GC analysis was performed using tridecane as an internal standard.

Acknowledgments

The authors would like to thank ANR (11ECOT 011 01), ADEME, FEDER programme for financial supports. Mr. Robert Feldman is acknowledged for the text proofreading.