1 Introduction

How the texture of white and grey cement-based materials behaves over long times and how to follow the aging of these building materials? Answering these questions is particularly important for improving the sustainability and mechanical performance of these building materials and for limiting the necessary CO2 emission required for their production. Moreover, a real and noninvasive multiscale experimental approach must be used to answer these questions. For instance, long-term durability is closely related to unsaturated moisture transport on different length scales of these materials. Among the different techniques, nuclear magnetic relaxation is probably one of the most appropriate experimental approaches to study continuously the evolution of the microstructure of these highly disordered materials.

Several attempts have already addressed the question, but only in the early aged of the materials [1]. In this case there is always enough liquid species in the intricate porosity of the material to achieve a good NMR signal. However, to follow the characteristic features of aging of the material over a long period of time, a sufficiently sensitive NMR technique should be used.

It is well known that hardened cement pastes exhibit a threefold hierarchy pore structure: intra-CSH (hydraulic binder) microscale (below 2 nm), mesopore structure at a scale ranging from 2 to 50 nm and capillary (macro) pore network above 50 nm [2]. To study this material, we are currently studying the moisture transport at different water filling, controlled by temperature and relative humidity ratio, by using a proton NMR multiscale approach including PFG diffusometry, field cycling relaxometry and spectroscopy correlated with T1, T2 and T1ρ measurements. Here, we report two particular studies. First, we present a proton NMR relaxation study of hardened grey and white CEM I Portland cement pastes that shows different pore size hierarchies for these two materials. Second, we focus on the grey cement to show the effects of different degrees of humidity on the transport of moisture during the aging.

2 Materials and experiments

Cement pastes are prepared at 20 °C by mixing anhydrous grey or white CEM I powder and distilled water with a water-to-cement mass ratio w/c = 0.5. After 24 h, the material is kept in a saturated limewater solution to prevent the autodesiccation of the pores. Then, longitudinal relaxation NMR experiments by inversion recovery are performed at a proton Larmor frequency of 360 MHz on these materials in different conditions. Evolutions of longitudinal proton magnetizations are analysed by a “curve-peeling” method as illustrated on Fig. 1. First, one extracts an exponential at long times on the raw data (curve a on Fig. 1.1). Then, we iteratively continue this extraction of exponentials at long times after subtraction of the previous exponential until we reach a mono-exponential behavior (curves b, c, d, e on Figs. 1.1 and 1.2). Finally, we verify the accuracy of the curve peeling procedure by reintroducing all the exponential components to compare with the raw data of longitudinal magnetization decay (Figs. 1.3 to 1.7). This “curve-peeling” analysis leads to a proton population distribution (1H-P.D.) expressed through the weighting factors Ai vs. the longitudinal relaxation times T1i (Fig. 1.8).

Different steps of the “curve-peeling” method are used to extract successively five exponential components from the magnetization raw data (curves 1.1 and 1.2) and shown on semi-logarithmic plots. Then the exponential components are summed step by step (curves 1.3 to 1.7). Logarithmic plots of the five extracted weight factors Ai vs. the five relaxation times T1i shown on curve 1.8 exemplify a proton population distribution (1H-P.D.) of a grey CEM I paste hydrated 5 days with w/c = 0.5 at 20 °C.

3 Results and discussion

3.1 Comparison of data obtained from grey and white cement pastes

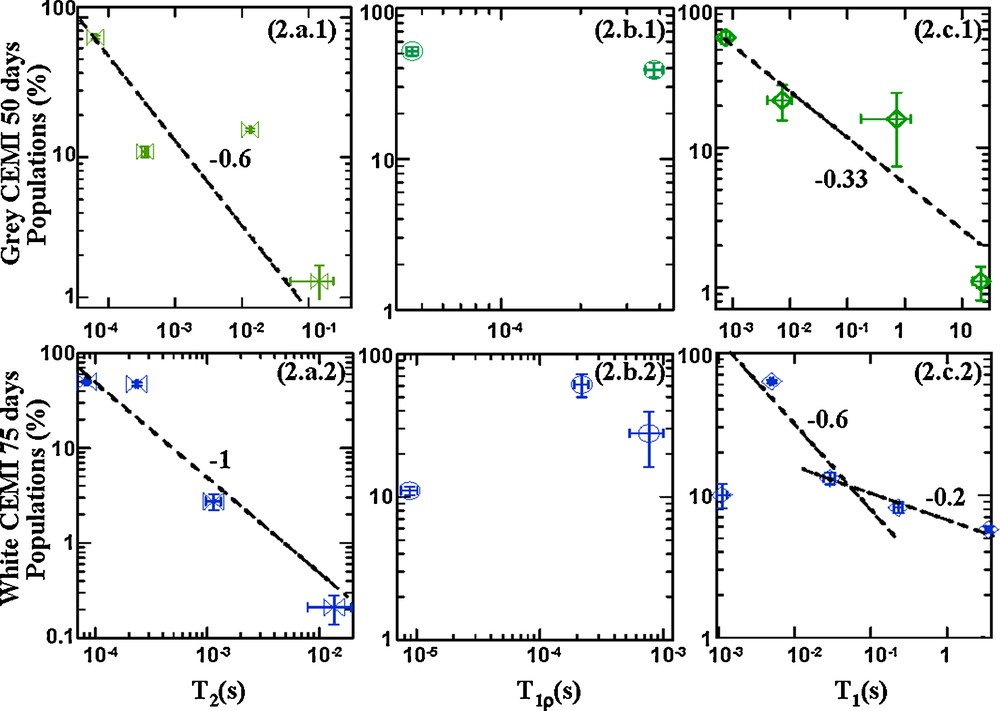

We present on Fig. 2 logarithmic plots of 1H-P.D. vs. the relaxation times T2i, T1ρi and T1i (2.a._, 2.b._, 2.c._, respectively) obtained for 50 days-aged grey (2._.1) and 75 days-aged white (2._.2) CEM I pastes. In these cement pastes, the nuclear relaxation process is mainly controlled by paramagnetic ferric ions [3] and well understood using a biphasic fast exchange model [4] leading to a proportionality relation between Tλ with λ ∈ {1, 2, 1ρ} and the volume to surface ratio of pores V/S which defines an average NMR pore radius <R>NMR α Tλ. Halperin et al. have demonstrated the validity of the biphasic fast exchange model for cement pastes, showing the linear relation between the relaxation times and the volume-to-surface ratio of the pores or average pore size [5]. These results confirm the discrete distributions of pore sizes previously found for similar materials but at the early-aged period [1]. Here, the originality results in the possibility to obtain such structural information well after the complete hydration of the materials. These data have been obtained by pulse sequence operating at different frequencies showing unambiguously the following features:

- • one observes power laws with different exponents for the 1H-P.D. obtained from the T2i data (Fig. 2.a._) for both materials but in different time scales. For the grey cement, the exponent of −0.6 is similar to the ones previously found from the T1i in C3S paste [6]. For the white cement, one notes a net enhancement of the exponent with a value of −1. Such a difference reveals a more hierarchical drying process in white than in grey cement. Often, a power law for a pore size distribution indicates a scale invariance of the data or equivalently a hierarchy of pore sizes. These differences of exponents and time scales indicate clearly distinct drying behavior at large scales for the grey and white cement;

- • the 1H-P.D. found from T1i data (Fig. 2.c._) confirms the different behaviours obtained for both materials. The very long T1 = 10 s is characteristic of portlandite crystals and should not be considered as giving any pore size information. However, the macroscopic and microscopic scales do not follow the same distribution laws for the two materials evidencing again distinct drying behaviour at large scales for the grey and white cement;

- • T1ρi is limited due the higher power involved in the measurement which limits the dynamics needed to follow a large hierarchical behaviour.

Fig. 2 reports logarithmic plots of 1H-P.D. vs. the relaxation times T2i, T1ρi and T1i (2.a._, 2.b._, 2.c._, respectively) obtained for 50 days-aged grey (2._.1) and 75 days-aged white (2._.2) CEM I pastes.

3.2 Effect of aging of grey CEM I cement paste

We present on Fig. 3 the proton T1i distribution for grey CEM I cement in different conditions of drying and aging. In condition 1 (Fig. 3.1), the material is used after a 5 days setting delay. In condition 2 (Fig. 3.2), the material is dried during 3 days under vacuum in a oven after an aging period of 2 months at 25 °C and R.H. = 50%. Finally, in condition 3 (Fig. 3.3), the same material is hydrated again during one month at 25 °C and R.H. = 90% using a saturated water solution by BaCl2 salt. These data reveal the following points:

- • at five days, the observed data follow two power laws with a negative and positive exponents at small and large scales, respectively. This is not a surprising result for a material that does not achieve a complete hydration;

- • after 50 days of aging and 3 days drying process, one observes a 1H-P.D. that follows a unique power law over a large range of relaxation time scale, without counting the longest T1 of 10 s coming from portlandite crystals. Here the microstructure is not modified by the drying process which impacts mainly on the macrostructure range;

- • after 90 days and 30 days of hydration at R.H. = 90%, we restore the distribution corresponding to the macro pore range. The drying processes following these three steps show that only the macro pore populations are involved in the overall drying process. The net change in the sign of the exponent at 5 and 90 days for small and large length scales can be formally understood by either a surface proton distribution S(R) = <R>2-Df in the region of small length scales or a volume proton distribution V(R) = <R>3-Df in large length scales where Df is a fractal dimension between 2 and 3 [7]. The overall behavior of these distributions thus shows the very good sensitivity of our method of analysing the drying history of the material.

Fig. 3 reports successively 1H-P.D. vs. T1 of a 5 days setting grey CEM I (Fig. 3.1), then of the same material dried 2 months later (Fig. 3.2), and finally of the same dried material hydrated at R.H. = 90% during one month (Fig. 3.3). The dotted lines underline the power law behavior of the proton distributions.

4 Conclusions

The main results of this study are twofold. (i) A proton NMR relaxation study of hardened grey and white CEM I Portland cement pastes shows very different pore size hierarchies for these two materials. (ii) We prove the good sensitivity of our method for analysing the evolution of the pore size dependencies under drying and wetting history of the material. We believe that the proposed method could be very useful for studying the durability of building material under conditions of extreme use.

Acknowledgements

This work has been supported by a grant from a CPR contrat pour la recherche between CNRS and Association technique de l’industrie des liants hydrauliques (ATILH).